Subfloor Plywood: Types, Thickness & How to Choose the Right Plywood for Subflooring

Subfloor plywood plays a foundational role in any floor system, directly affecting strength, stability and long-term durability. Whether you are constructing a new residential building, renovating an interior space, or reinforcing a garage loft, selecting the correct plywood for subflooring is a technical decision that should not be overlooked. The wrong choice can result in sagging floors, excessive noise, moisture-related damage, and costly repairs.

Despite its importance, many builders and homeowners remain uncertain about which plywood to use, how thick it should be, and whether plywood or OSB is the better option. This article provides a comprehensive, practical guide to subfloor plywood, addressing the most common questions and helping you make informed decisions based on real-world construction requirements.

What is Subfloor Plywood?

Subfloor plywood refers to structural plywood panels installed directly on top of floor joists to form the primary load-bearing layer of a floor system. Its purpose is to distribute weight evenly across the joists, reduce deflection, and create a stable base for the finished flooring above.

It is important to distinguish subfloor plywood from underlayment, as these two layers serve different functions. The subfloor is a structural element designed to support loads and maintain rigidity, while underlayment is a thinner, non-structural layer installed above the subfloor to smooth the surface, improve moisture resistance, or enhance sound insulation. Confusing these layers often leads to incorrect material selection and compromised floor performance.

Because subfloor plywood carries structural loads, it must meet specific strength and bonding standards that interior or decorative plywood products do not satisfy.

Why Plywood is commonly used for Subfloors

Plywood has remained a preferred subfloor material for decades due to its balanced combination of strength, durability, and reliability. Its manufacturing process involves bonding multiple layers of wood veneer with alternating grain directions, a technique that significantly improves dimensional stability and resistance to bending.

This cross-laminated structure allows plywood to handle both static and dynamic loads effectively. As a result, plywood subfloors perform well under foot traffic, furniture loads, and even heavier storage requirements. Compared to particle-based panels, plywood also responds better to occasional moisture exposure. While no wood product is entirely immune to water damage, plywood tends to retain its structural integrity longer and dries more evenly when moisture intrusion occurs.

Another reason plywood is widely used for subfloors is its compatibility with virtually all finished flooring materials. Hardwood, tile, laminate, vinyl, and carpet can all be installed over properly prepared plywood subfloors, making it a versatile choice for both residential and light commercial applications.

Types of Plywood Used for Subflooring

Selecting the correct type of plywood is essential for ensuring subfloor performance and longevity. Different plywood products are designed for different structural and environmental conditions.

CDX Plywood

CDX plywood is one of the most commonly used materials for subflooring in residential construction. It is manufactured with C-grade and D-grade surface veneers and bonded using exterior-rated adhesive. The rough surface appearance of CDX plywood is not a disadvantage in subfloor applications because it is intended to be covered by underlayment or finished flooring.

CDX plywood offers a practical balance between cost and structural performance. It is suitable for most standard residential subfloors when installed correctly and protected from prolonged moisture exposure.

Exterior Grade Plywood

Exterior grade plywood uses waterproof adhesives and higher-quality veneer bonding than standard interior plywood. It is designed to withstand higher humidity levels and occasional moisture contact, making it suitable for subfloors in kitchens, bathrooms, and entry areas where moisture risks are greater.

Although exterior plywood is more expensive than CDX, it provides additional protection against delamination and long-term degradation in demanding environments.

Tongue and Groove Plywood

Tongue and groove plywood panels are engineered with interlocking edges that connect adjacent sheets. This design creates a more unified subfloor surface and reduces vertical movement between panels. As a result, tongue and groove plywood significantly reduces floor squeaking and improves overall stiffness.

This type of plywood is especially recommended for subfloors installed over wider joist spacing or in areas where enhanced load distribution is required.

Structural or Construction Plywood

Structural-grade plywood is designed for applications that demand higher load-bearing capacity. It is commonly used in garage floors, lofts, workshops, and storage areas where standard residential loads are exceeded. This plywood type is often paired with greater thickness to ensure sufficient stiffness and long-term performance.

What Size Plywood for Subfloor?

The most commonly used plywood sheet size for subflooring is four feet by eight feet. This size has become the industry standard because it provides efficient coverage while remaining manageable during installation. It allows installers to stagger joints effectively across joists, which improves load distribution and structural integrity.

While larger sheet sizes are available for certain commercial or industrial applications, they are less commonly used in residential subfloors due to handling difficulties and limited compatibility with standard framing layouts.

Thickness selection is equally important and must be aligned with structural requirements. Typical subfloor plywood thicknesses range from five-eighths of an inch to one inch, depending on joist spacing and expected load conditions.

How Thick Should Plywood Subfloor Be?

Thickness is one of the most critical factors affecting subfloor performance. Using plywood that is too thin often leads to excessive deflection, floor movement, and premature failure.

In standard residential construction with joists spaced sixteen inches on center, a minimum plywood thickness of five-eighths of an inch is generally accepted. However, many builders choose three-quarter-inch plywood even in these conditions to increase stiffness and reduce long-term deflection. When joist spacing increases to twenty-four inches on center, three-quarter-inch plywood becomes the minimum recommended thickness.

How Thick should Plywood Subfloor be in a Garage Loft?

Garage lofts present a more demanding structural environment than typical living spaces. These areas often support heavy storage loads, equipment, or workshop activities. For garage loft applications, three-quarter-inch structural-grade plywood should be considered the minimum acceptable thickness. In cases where loads are especially heavy or concentrated, one-inch plywood or reinforced double-layer systems provide significantly better performance and safety margins.

Choosing insufficient thickness in a garage loft frequently results in sagging floors and reduced load-bearing capacity over time.

5 factors that Affect Thickness choice

Choosing the correct plywood thickness for a subfloor is not a one-size-fits-all decision. Several technical and practical factors directly influence how thick the plywood should be in order to ensure structural stability, long-term durability, and compliance with building standards.

Joist Spacing

Joist spacing is one of the most critical factors affecting subfloor thickness. The wider the spacing between joists, the more load the plywood panel must carry on its own. When joists are spaced sixteen inches on center, thinner plywood can perform adequately because the load is distributed more frequently. However, as spacing increases to twenty-four inches on center, the subfloor panels must span a greater distance, which significantly increases deflection if the plywood is not thick enough. In these cases, thicker plywood is necessary to prevent floor bounce, sagging, and long-term structural fatigue.

Expected Load and Usage

The amount of weight a floor is expected to support plays a major role in thickness selection. Residential living spaces typically experience moderate, evenly distributed loads from foot traffic and furniture. In contrast, areas such as garage lofts, storage rooms, or workshops are often subjected to heavier and more concentrated loads from equipment, tools, or stacked materials. As load intensity increases, thicker plywood is required to maintain stiffness and prevent permanent deformation over time.

Type of Finished Flooring

The finished flooring installed above the subfloor also influences plywood thickness requirements. Flexible flooring materials such as carpet or vinyl can tolerate minor subfloor movement without visible issues. Rigid flooring materials, including ceramic tile, stone, and hardwood, demand a much stiffer subfloor to prevent cracking, joint failure, or surface irregularities. In these cases, using thicker plywood or reinforced subfloor systems becomes essential to support the finished surface properly.

Environmental Conditions and Moisture Exposure

Environmental conditions, particularly humidity and moisture exposure, affect how plywood performs over time. In areas where temperature and humidity fluctuate significantly, thinner plywood is more prone to expansion, contraction, and warping. Locations such as kitchens, bathrooms, basements, and entryways often require thicker plywood with higher structural stability to compensate for environmental stress and reduce the risk of moisture-related damage.

Local Building Codes and Structural Standards

Local building codes and construction standards often specify minimum subfloor thickness based on joist spacing, building type, and intended use. These requirements are designed to ensure safety, durability, and consistent performance. Ignoring code requirements can lead to inspection failures and long-term structural risks. For this reason, plywood thickness should always be selected in accordance with applicable regulations, even if thinner panels appear sufficient at first glance.

OSB vs Plywood Subfloor: Which Is Better?

The debate between OSB and plywood for subflooring is common in modern construction. While both materials are engineered wood panels, they behave differently under real-world conditions.

Plywood generally provides better long-term load performance due to its layered veneer structure. It resists bending and fastener pull-out more effectively, especially under dynamic loads. OSB, while initially strong, tends to lose stiffness more quickly when exposed to repeated stress.

Moisture performance is another key difference. OSB absorbs moisture more slowly than plywood, but once saturated, it swells significantly and dries slowly. This swelling often remains permanent and can compromise floor flatness. Plywood, on the other hand, dries faster and is less prone to irreversible edge swelling.

Cost is one area where OSB has an advantage, as it is typically less expensive than plywood. However, the initial savings may be offset by reduced durability in environments where moisture or long-term performance is a concern.

How to Choose the Right Subflooring Plywood

Choosing the right plywood for subflooring requires evaluating both material specifications and project conditions. Plywood intended for subfloors should always have an exterior-rated or exposure-rated adhesive, even in interior spaces. This ensures resistance to humidity and occasional moisture intrusion.

Edge design also matters. Tongue and groove panels provide better structural continuity and are generally preferred over square-edge panels for subfloor applications. Core quality and adhesive bonding play a crucial role in preventing delamination and maintaining stiffness over time.

While budget considerations are important, selecting lower-grade or thinner plywood often leads to higher long-term costs due to repairs and reduced lifespan. Investing in appropriate thickness and quality at the subfloor stage typically results in better overall floor performance.

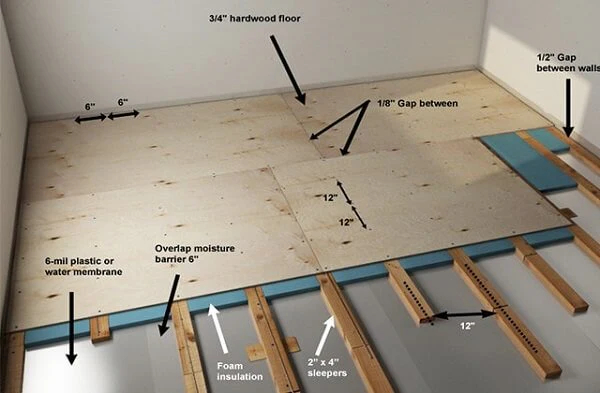

How to Install Plywood Subfloor Correctly

Proper installation is essential to achieving the full benefits of a plywood subfloor. Floor joists must be level, dry, and securely fastened before installation begins. Any damaged or uneven joists should be corrected to prevent future issues.

Plywood panels should be laid out with staggered joints to improve load distribution. Small expansion gaps must be left between sheets to allow for seasonal movement and prevent buckling. Panels should be fastened using appropriate screws or nails, following recommended spacing patterns to ensure secure attachment without overdriving fasteners.

Before installing underlayment or finished flooring, the subfloor should be inspected for movement, unevenness, or squeaks. Addressing these issues early prevents more complex problems later.

Common Mistakes When Using Plywood for Subfloor

Many subfloor failures can be traced back to a few common mistakes. Using interior-grade plywood instead of structural or exterior-rated products is one of the most frequent errors. Choosing insufficient thickness, failing to allow for expansion gaps, and improper fastening patterns also significantly reduce subfloor performance. In moisture-prone environments, skipping vapor barriers or moisture protection further increases the risk of long-term damage.

Avoiding these mistakes greatly improves the durability and reliability of plywood subfloors.

FAQs About Subfloor Plywood

What plywood for subfloor is best for bathrooms or kitchens?

Exterior-grade or exposure-rated plywood provides better resistance to humidity and moisture and is recommended for these areas.

OSB or plywood for subfloor – which lasts longer?

Plywood generally offers superior long-term durability, particularly in environments where moisture exposure or heavy loads are expected.

Can I use two layers of thin plywood instead of one thick sheet?

Using two layers can increase stiffness, but it requires careful installation, proper adhesive bonding, and correct fastening to be effective.

Is plywood subfloor suitable for tile or hardwood flooring?

Plywood subfloors are suitable for both tile and hardwood flooring, but tile installations require thicker, stiffer subfloors and additional underlayment.

Conclusion

Subfloor plywood is a critical structural component that directly influences the performance and lifespan of a floor system. Selecting the right plywood type, thickness, and installation method ensures stability, reduces maintenance issues, and supports a wide range of finished flooring materials.

For most applications, structural-grade plywood with sufficient thickness remains the most reliable choice, particularly in high-load areas such as garage lofts. Understanding these principles allows builders and homeowners to make informed decisions and achieve durable, high-quality flooring systems.

Bình luận