Plywood Grades Explained: Types, Charts, Uses & How to Choose the Right Grade

Plywood is one of the most versatile engineered wood products used in construction, furniture manufacturing, and interior design. From structural applications such as flooring and wall sheathing to high-end cabinetry and architectural features, plywood offers a balance of strength, stability, and aesthetic flexibility that few other materials can match.

However, not all plywood is the same. One of the most misunderstood yet critical aspects of plywood selection is grading. Understanding plywood grades is essential for choosing the right material for a specific application, ensuring the desired appearance, performance, and durability while avoiding unnecessary costs or structural risks.

This guide explains plywood grades in detail, covering different grading systems, wood species, use cases, and how to select the right plywood grade for your project.

What Are Plywood Grades?

Plywood grades are a standardized way of classifying plywood based on the quality of its surface veneers, allowable defects, and intended use. Grading does not measure thickness or overall strength directly. Instead, it primarily describes the appearance and finish quality of the face and back veneers, as well as the bonding standards used in production.

Depending on the region, plywood grading systems may be governed by organizations such as the APA in North America or EN standards in Europe. While the terminology may vary slightly, the underlying principle remains the same: higher grades indicate better surface appearance, fewer defects, and greater suitability for visible or decorative applications.

It is also important to understand that plywood grading is often applied separately to the front and back faces. As a result, a single plywood sheet can have different grades on each side.

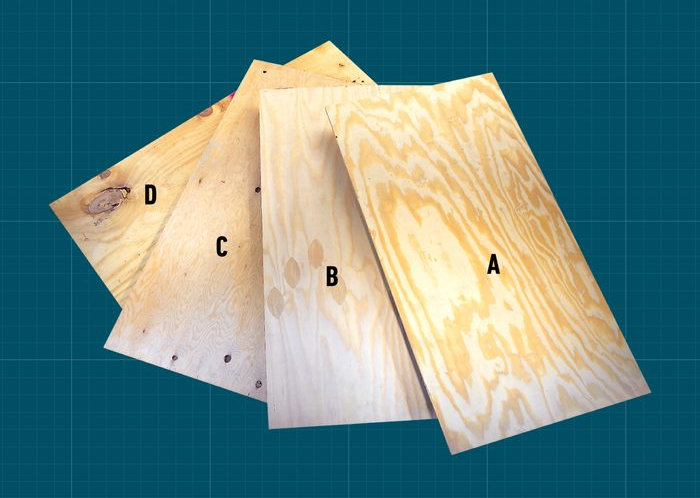

4 Grades of Plywood Explained

One of the most common plywood grading systems uses four main grades: A, B, C, and D. These grades describe the visual quality of the veneer face rather than the internal structure of the panel.

A-Grade Plywood

A-grade plywood represents the highest level of surface quality. The face veneer is smooth, uniform in color, and free from visible defects such as knots, splits, or patches. This grade is designed for applications where the plywood surface will remain visible and receive a clear or natural finish.

A-grade plywood is commonly used in furniture, cabinetry, wall paneling, retail interiors, and architectural features where aesthetics are a priority. Because of its superior appearance, A-grade plywood typically comes at a higher cost than lower grades.

B-Grade Plywood

B-grade plywood also offers a high-quality surface but allows for minor natural characteristics such as small, sound knots or subtle veneer repairs. These imperfections are structurally sound and do not affect performance, but they may be visible upon close inspection.

This grade is well suited for applications where the plywood surface will be painted, stained, or lacquered. B-grade plywood strikes a balance between visual appeal and cost efficiency, making it a popular choice for interior projects that require both durability and a refined finish.

C-Grade Plywood

C-grade plywood is intended for non-decorative or partially concealed applications. The face veneer may contain larger knots, filled defects, splits, or discoloration. Although these imperfections are repaired during manufacturing, the surface appearance is clearly affected.

C-grade plywood is commonly used in structural applications where appearance is not critical, such as subfloors, wall sheathing, and interior framing elements that will be covered by other materials.

D-Grade Plywood

D-grade plywood is considered a non-appearance grade. The veneer face may include open knots, unfilled defects, and noticeable surface irregularities. While this grade is not suitable for visible applications, it can still perform effectively in structural roles where aesthetics are irrelevant.

D-grade plywood is typically used in construction environments where the material will be fully concealed and protected from view.

Understanding Face and Back Grades

Plywood grading applies independently to the face and back veneers. This means that a single sheet can have different grades on each side, expressed using combinations such as AB, AC, or CD.

For example, AB plywood has an A-grade face and a B-grade back, making it suitable for applications where only one side is visible. CD plywood, on the other hand, has a C-grade face and a D-grade back and is generally reserved for structural uses.

Understanding face and back grading is especially important when plywood is used for cabinetry, shelving, or wall panels where both sides may be exposed or partially visible.

Grades of Plywood by Wood Type

Softwood Plywood Grades

Softwood plywood, typically made from species such as pine, fir, or spruce, commonly uses the A-D grading system. These grades are widely applied in construction-focused products such as sheathing, roofing, and subflooring.

One well-known example is CDX plywood, where the C and D grades describe the face and back veneers, and the “X” indicates the use of exterior-rated adhesive suitable for exposure to moisture during construction.

Hardwood Plywood Grades

Hardwood plywood grading often differs from softwood systems and may use alternative designations such as A1, A2, or similar classifications depending on the manufacturer or standard. Hardwood plywood is typically evaluated more strictly for surface appearance, as it is frequently used in furniture and interior design.

A1 hardwood plywood generally indicates a premium surface with minimal defects, suitable for high-end applications where visual consistency is essential.

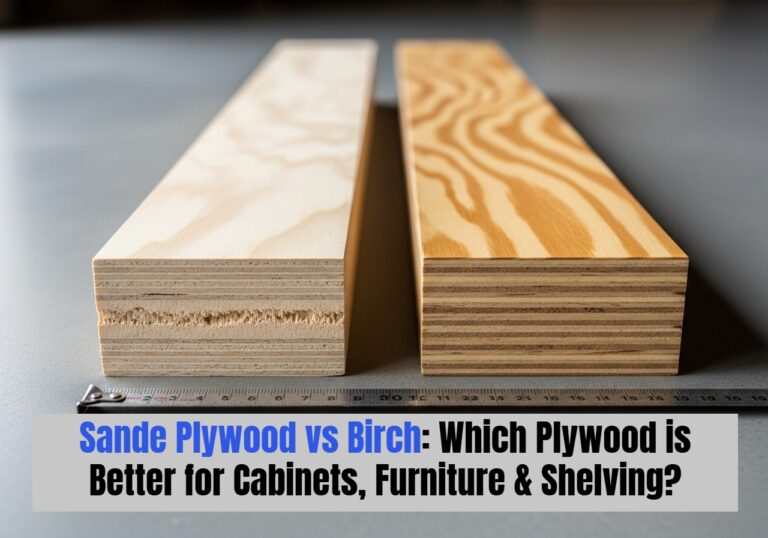

Birch Plywood Grades Explained

Birch plywood is valued for its light color, fine grain, and strength, making it a popular choice for furniture and interior applications.

Standard birch plywood grades focus heavily on veneer consistency and surface appearance. Higher grades feature smooth, uniform faces with minimal color variation, while lower grades allow for knots and repairs that are less visually appealing.

Baltic Birch Plywood Grades

Baltic birch plywood is a specific category known for its all-birch construction and high-quality core. Unlike standard birch plywood, Baltic birch often uses grading systems such as B/BB, BB/BB, or BB/CP.

These grades indicate the quality of both face veneers and allow for small, sound patches rather than open defects. Baltic birch plywood is prized for cabinetry, drawers, and precision woodworking due to its consistent thickness and strong core.

Marine Plywood Grades

Marine plywood is designed for high-moisture and demanding environments. While marine plywood grading still considers veneer quality, it places greater emphasis on adhesive performance and core integrity.

Marine plywood uses waterproof adhesives and high-quality veneers to resist delamination when exposed to water. It is commonly used in boat building, coastal construction, and outdoor structures where moisture resistance is critical.

It is important to note that marine grade does not necessarily mean the highest visual grade. Instead, it signifies superior bonding and durability under wet conditions.

Exterior Plywood Grades

Exterior plywood is manufactured with moisture-resistant adhesives and veneers suitable for outdoor or semi-exposed applications. Grading for exterior plywood often mirrors standard A–D systems but includes additional requirements for bonding performance.

Exterior grades are commonly used for siding, outdoor furniture, and structural elements exposed to weather. In many cases, exterior-grade plywood is sufficient for outdoor use, while marine plywood is reserved for constant or extreme moisture exposure.

Construction vs Project Plywood Grades

Construction plywood prioritizes structural performance over appearance. Grades used in construction applications are selected for strength, load-bearing capacity, and bonding reliability rather than surface finish.

Project plywood, on the other hand, is chosen with visual quality in mind. Furniture makers, designers, and interior contractors often prioritize higher face grades to achieve clean finishes and consistent aesthetics.

Understanding the difference between construction and project plywood helps avoid over-specifying materials where appearance is irrelevant or under-specifying materials where visual quality is critical.

Common Plywood Types and Their Grades

CDX plywood is one of the most recognizable construction-grade products. Its grading reflects its suitability for structural use rather than decorative applications. Sanded pine plywood, often available in higher grades, is commonly used indoors where a smoother finish is required.

Baltic birch plywood stands apart due to its grading consistency and premium core construction, making it a preferred choice for high-precision and design-focused projects.

Plywood Grades Chart and Practical Reference

Plywood grades charts are commonly used as quick-reference tools to compare appearance quality, typical uses, and exposure suitability. These charts help users understand how different grades align with specific applications, from visible furniture surfaces to concealed structural elements.

While charts provide a helpful overview, selecting plywood should always involve evaluating project requirements rather than relying solely on grade labels.

Plywood Grades and Uses

Plywood grades directly influence where and how a material should be used. High-grade plywood is ideal for furniture, cabinetry, and architectural features where appearance matters. Mid-grade plywood serves well in painted or semi-visible applications. Lower grades are best suited for structural roles such as subflooring, wall sheathing, and roof decking.

Matching the plywood grade to its intended use ensures both performance and cost efficiency.

5 tips to choose the right Plywood Grade for your project

Choosing the right plywood grade begins with identifying whether appearance or structural performance is the primary concern. Projects that prioritize aesthetics benefit from higher face grades, while structural applications require reliable bonding and sufficient thickness.

Tip 1: Identify Whether Appearance or Structural Performance Matters More

Start by defining the role of plywood in your project. Visible applications such as furniture or wall panels require higher face grades for a clean finish, while structural uses like subfloors or sheathing prioritize bonding quality and strength over surface appearance.

Tip 2: Evaluate Environmental Exposure

Plywood used in humid or moisture-prone areas needs more than a good surface grade. Always consider exposure conditions and choose grades combined with suitable adhesive and moisture resistance to ensure long-term durability.

Tip 3: Match the Grade to the Final Finish

Clear or natural finishes demand higher plywood grades to avoid visible defects. Painted or laminated surfaces can tolerate mid-grade plywood, allowing cost savings without compromising the final appearance.

Tip 4: Balance Cost With Long-Term Value

Choosing the lowest grade to save cost often leads to additional finishing or replacement later. Selecting a slightly higher grade than the minimum requirement usually delivers better durability, flexibility, and overall value.

Tip 5: Check Standards and Supplier Consistency

Plywood grading can vary by region and manufacturer. Always review project specifications and work with reliable suppliers to ensure grade consistency across face and back veneers.

Common Mistakes When Choosing Plywood Grades

One common mistake is confusing plywood grade with thickness or strength. Another is using appearance-grade plywood in structural applications where durability matters more than finish. Failing to understand face and back grading can also lead to unexpected results, particularly in visible installations.

Avoiding these errors helps ensure the selected plywood performs as intended.

FAQs About Plywood Grades

What do plywood grades mean?

Plywood grades describe the visual quality and allowable defects of the veneer surfaces, not the thickness or overall strength of the panel.

Which plywood grade is best for furniture?

Higher grades such as A-grade or premium hardwood grades are best for furniture due to their smooth, defect-free surfaces.

Is marine plywood always the highest grade?

Marine plywood refers to moisture resistance and bonding quality rather than surface appearance. It may not always have the highest visual grade.

What is the difference between birch and Baltic birch plywood grades?

Baltic birch plywood uses specialized grading systems and features a more consistent core compared to standard birch plywood.

Kosemex – A Leading Plywood Supplier in Southeast Asia

Kosemex is a trusted plywood manufacturer and exporter based in Southeast Asia, supplying high-quality plywood products to international markets across Europe, the United States, and other global regions. With a strong focus on quality control, compliance, and production consistency, Kosemex supports a wide range of construction, furniture, and interior design projects.

All plywood products are manufactured in accordance with internationally recognized standards and certifications, including CE marking for the European market and FSC® certification for responsible forest management. These certifications ensure that Kosemex plywood meets strict requirements for safety, sustainability, and traceability.

One of Kosemex’s key strengths lies in its large-scale and stable supply capacity. With modern production facilities and well-managed raw material sourcing, Kosemex is able to deliver consistent quality and reliable volumes, even for high-demand and long-term projects. This makes the company a preferred partner for importers, distributors, contractors, and OEM customers seeking dependable plywood solutions.

By combining certified quality, export experience, and flexible production capabilities, Kosemex positions itself as a reliable plywood supplier for partners looking to balance performance, compliance, and long-term value.

Contact Kosemex for product specifications, samples, or commercial inquiries:

WhatsApp: +84 399 741 589

Email: anna@kosmexgroup.com

Conclusion: Why the Right Plywood Grade Makes All the Difference

Understanding plywood grades is essential for selecting the right material for any project. The correct grade ensures the desired balance of appearance, durability, and performance while preventing unnecessary costs or structural issues.

By aligning plywood grade with application requirements, builders, designers, and manufacturers can achieve better results and longer-lasting outcomes. Choosing the right grade is not just a technical decision but a critical factor in the success of any plywood-based project.

Bình luận