Why Kosmex is trusted for Eucalyptus plywood for EU market

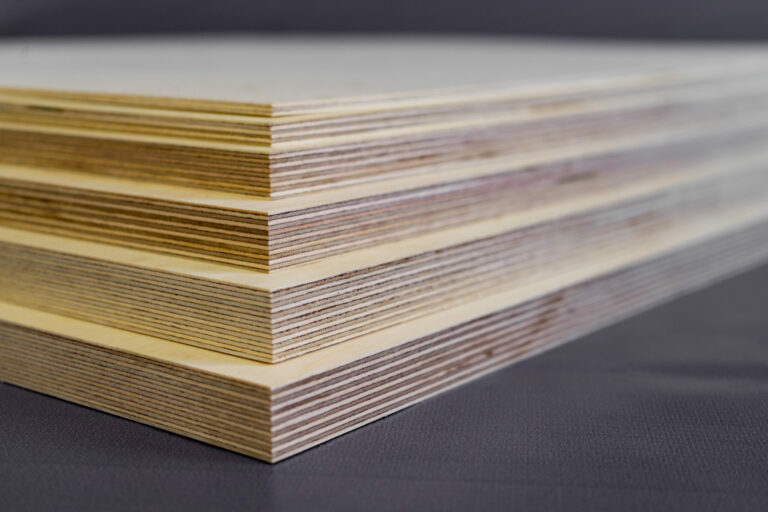

European buyers are now scrutinising Eucalyptus plywood for EU market sourcing more closely than ever. Birch prices continue to rise, compliance rules are tightening, and customers expect panels that perform consistently—not just attractive brochures.

This guide is written for furniture factories, plywood wholesalers and construction contractors who need plywood that meets EN 636-2, EN 314-2 Bond Class 2 and CE2+ expectations. It explains how Vietnam suppliers differ, why phenolic glue matters, and how to evaluate which eucalyptus plywood options will actually work in your factory or job site.

Who actually buys eucalyptus plywood from Vietnam – and why

Demand for Eucalyptus plywood for EU market sourcing mainly comes from three segments:

- Furniture factories & OEM manufacturers: They use eucalyptus or mixed hardwood cores to reduce carcass cost while keeping screw-holding strength and dimensional stability strong enough for humid apartments and kitchens.

- Plywood wholesalers & import distributors: They build “good–better–best” product ranges and need reliable mid-tier and structural options that meet EN standards—not just commercial-grade boards.

- Formwork & construction contractors: They look for film-faced panels with predictable reuses, strong edges and resistance to storage moisture on site.

Across all three segments, buying decisions come down to the same question:

Which supplier can provide eucalyptus plywood that performs consistently and comes with clean, verifiable EUTR/EUDR documentation?

Standards, numbers and glue systems that really matter

Before we get into the technical details, it’s worth noting something I’ve seen in many EU sourcing discussions: buyers don’t care about marketing language once production risks are involved. That’s why, once they move past the glossy samples and into technical sheets, a clear pattern appears.

Serious offers for Eucalyptus plywood for EU market projects share three pillars: clearly stated standards, basic physical data and honest glue descriptions.

Standards and intended use

Instead of vague phrases like “waterproof board”, look for explicit references such as:

- EN 636-2 – plywood for humid conditions, used in kitchens, bathrooms, protected external areas and much formwork.

- EN 314-2 Bond Class 2 – bond quality suitable for humid service, not just dry rooms.

- CE2+ – structural conformity level under EN 13986, relevant when panels are used as load-bearing components rather than only decorative linings.

These standards form the baseline when evaluating any Eucalyptus plywood for EU market products intended for humid or structural use.

Key technical data

From what I’ve observed when comparing Vietnam and Eastern European suppliers, technical data becomes the fastest way to filter serious mills from casual exporters. Typical technical sheets for eucalyptus-core panels quote ranges like:

- Density: roughly 560–650 kg/m³ at 8–12% moisture.

- Moisture content at dispatch: typically 8–12%.

- Thickness tolerance (calibrated panels): often around ±0.3 mm on thicknesses such as 12–21 mm.

- Screw-holding performance: face screw withdrawal commonly in the 1,500–2,500 N range.

With a data sheet like this in hand, it becomes much easier to compare Vietnam products against existing birch, poplar or pine specs used in EU factories, and to judge whether a particular Eucalyptus plywood for EU market option really fits your application.

Glue systems and boiling tests

For EU buyers, glue is often the real deal-breaker.

- Normal eucalyptus plywood: uses MR or melamine-UF systems—adequate for interiors but unreliable under long-term humidity.

- Structural eucalyptus plywood: uses phenolic WBP glue, engineered to resist severe moisture cycles.

Phenolic lines built for EU standards are typically designed to withstand extended boiling tests (up to 72 hours) without delamination.

This level of performance is what makes phenolic eucalyptus plywood suitable for Service Class 2 structural use, formwork and high-humidity furniture applications.

This is the single biggest difference between normal eucalyptus plywood and a Vietnam-made phenolic Eucalyptus plywood for EU market line engineered for serious humidity exposure.

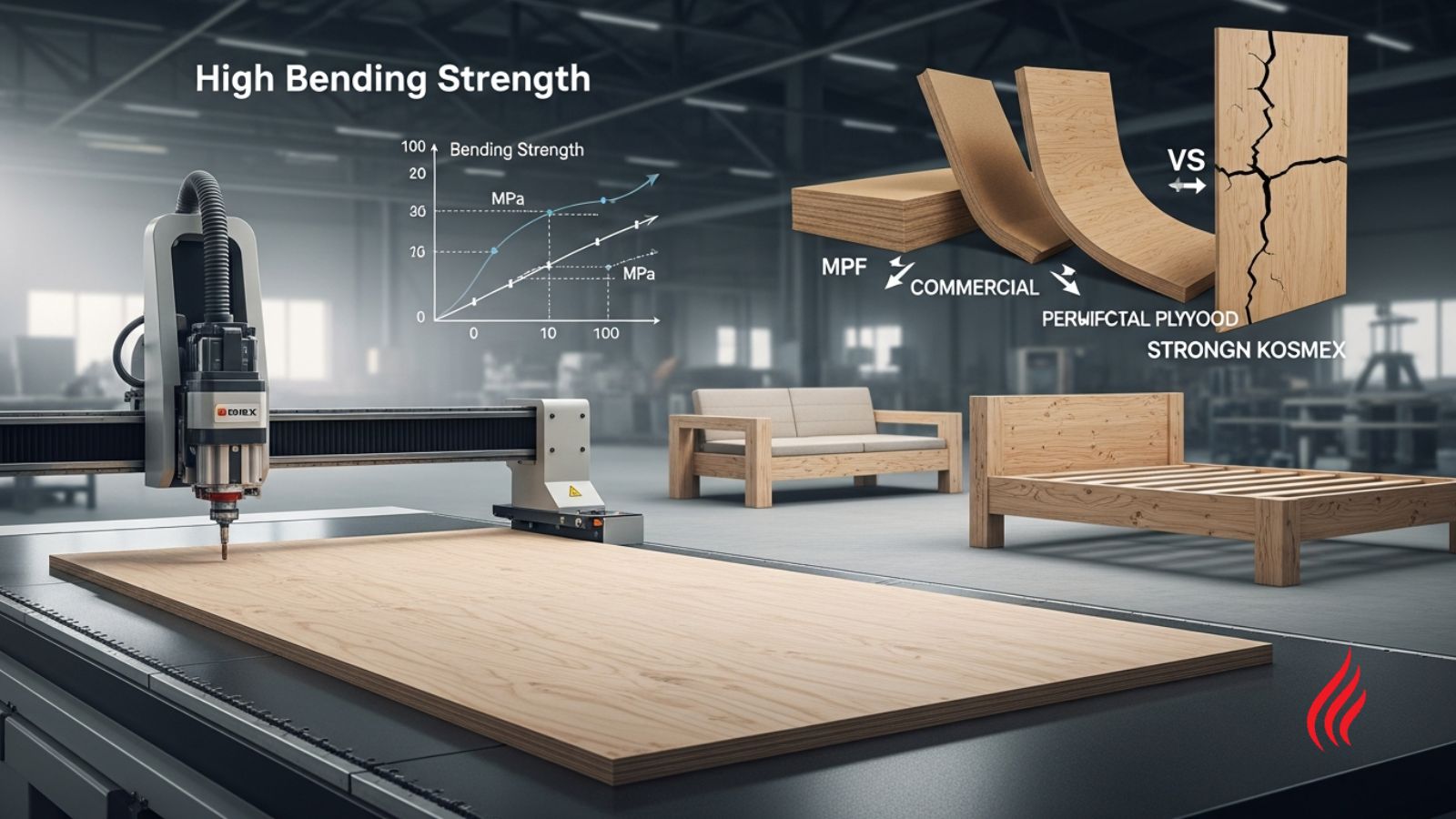

Normal eucalyptus plywood vs Kosmex Eucalyptus phenolic glue plywood

When I explain plywood differences to EU customers, I’ve noticed that the conversation becomes clearer when they see real trade-offs side by side. Price is rarely the main issue—risk, reject rates and glue behaviour matter far more. That’s why the table below focuses on the differences that actually affect production and field performance.

| Feature | Normal eucalyptus plywood (MR / melamine) | Kosmex Eucalyptus phenolic plywood (EN 636-2 / CE2+ oriented) |

| Typical use | Low-cost carcasses, light shelving, packaging; low-risk indoor applications | Structural/semi-structural cabinet parts, humid-area carcasses, shopfitting, subfloors, film-faced formwork |

| Glue system | MR or melamine-UF; moisture-resistant but not waterproof; not suited for prolonged humidity | Phenolic WBP glue engineered for harsh moisture cycles; reference adhesive system for structural + formwork plywood |

| Boiling/moisture performance | Swelling and delamination risk under extended moisture; limited reuse in formwork | Designed to withstand 72-hour boiling cycles with no glue-line failure on specified product lines |

| Standards focus | Often “commercial grade”, or EN 636-1 only; not intended for structural use | Developed around EN 636-2 + EN 314-2 Bond Class 2, with selected film-faced items supporting CE2+ structural applications |

| Service class fit | Dry or mildly humid interior environments | Service Class 2: humid interiors, protected exterior zones, and load-bearing formwork |

| Dimensional accuracy | Looser tolerances; inconsistent calibration increases rework in automated lines | Calibrated thickness with tighter tolerances (≈ ±0.3 mm); ideal for CNC machining + stable assembly |

| Documentation & compliance | Basic CO/packing list; limited technical/legal paperwork | Full technical data sheets, CE info (where applicable), legality + species documents supporting EUTR/EUDR |

| Life-cycle cost | Cheap upfront but higher risk of swelling, edge breakdown, rejects and formwork failures | Higher unit price but lower real project cost thanks to reduced rejects, fewer failures and longer formwork life |

Inside a realistic factory trial

European factories rarely switch plywood specifications overnight. Before accepting any Eucalyptus plywood for EU market option, they follow a structured trial process to verify performance, machining behavior and long-term stability.

Paper screening

A mid-sized kitchen manufacturer in southern Germany is under pressure: birch prices keep climbing and margins are shrinking. The purchasing team asks three Vietnam suppliers for full technical documentation.

Kosmex stands out because their pack includes EN 636-2 and EN 314-2 Bond Class 2 references, CE2+ information for selected formwork lines, calibrated thickness data, moisture and density ranges, and 72-hour boiling test results for phenolic boards.

The documentation is clear enough for the engineering team to move forward. In Germany, buyers rarely entertain offers without glue-line test data; too many projects have failed because MR panels were supplied without proof of bond quality.

Sample run

A trial pallet arrives on a Friday afternoon. The production manager, a line supervisor and a senior operator pull out several boards for quick checks:

cutting, edging, CNC routing, hinge mounting and edge stability.

One operator runs his hand along a freshly machined edge and notes that it “feels closer to birch than the low-grade boards we tested last year.” Small comments like this often influence the early stages of decision-making more than people think. Operators have rejected entire specifications simply because the edges felt fragile long before lab data confirmed anything.

Stress testing

Offcuts go into the factory’s small test room. Pieces are soaked, boiled and cut open to assess glue-line integrity. Moisture content is measured against the declared 8–12% range. Edges are checked for swelling, veneer lift and micro-cracks.

The phenolic eucalyptus panels hold together cleanly. A competing MR-bonded sample shows early veneer separation after an aggressive soak test—exactly the type of failure that causes problems in humid interiors and Service Class 2 environments. Many teams focus only on swelling during these tests, but ignoring glue-line behaviour often masks the real performance difference between MR and phenolic bonding.

Controlled line trial

The factory runs a six-week comparison:

Line A uses the phenolic eucalyptus spec, while Line B continues with birch.

Reject rates, tool wear, assembly time, carcass squareness and repair frequency are tracked carefully. Customer feedback is also monitored.

By week four, reject rates on the phenolic line drop noticeably and machining performance remains consistent. Savings begin to show up in labour and rework—factors that rarely appear in spreadsheet comparisons based solely on price per sheet.

Decision point

With engineering and finance aligned, the factory gradually shifts more SKUs to the new specification. Birch stays for premium lines, but most production moves to phenolic eucalyptus plywood because performance has been proven on their own line, not just in a supplier’s brochure.

This combination of technical evidence and operator feedback is why experienced EU buyers trust controlled trials. It turns Eucalyptus plywood for EU market sourcing from a “risky switch” into a data-backed decision.

What to expect from a serious EU-focused supplier

At this stage, most EU buyers already know roughly which mills look credible. The real difference shows up in how suppliers communicate. When you narrow down your shortlist for Eucalyptus plywood for EU market orders, a few behaviours signal that a mill understands European expectations.

Clear technical communication

Professional suppliers:

- explain which lines use phenolic glue and which remain MR or melamine;

- show how their internal tests connect to EN 636-2, EN 314-2 Bond Class 2 and CE2+ claims;

- recommend specific products for furniture factories, plywood wholesalers or formwork customers instead of offering one generic board.

This kind of dialogue helps you match individual products to real-world applications instead of guessing.

Consistent quality targets

Instead of soft promises, expect written targets for:

- density and moisture ranges;

- thickness tolerance and calibration strategy;

- face grade, repair criteria and putty policies.

That lets your incoming inspection teams line up their gauges and moisture meters with the numbers the mill is working to for each Eucalyptus plywood for EU market product.

Compliance-ready documentation

EUTR and EUDR expectations mean paperwork is now part of the product. A serious supplier will typically provide:

- species and origin declarations;

- legality and supply-chain documents;

- technical data sheets and test summaries formatted so you can drop them directly into your due-diligence system.

When auditors or customers ask for proof, having that documentation ready turns a stressful email into a routine reply and makes your Eucalyptus plywood for EU market sourcing defensible.

How to move from reading specs to testing real panels

If you’re reviewing options for Eucalyptus plywood for EU market sourcing, the most reliable next step is to examine real technical data and test how the boards behave in your own production environment.

Kosmex Company Limited – Vietnam

Office: No. 5, Lane 205/37/26 Xuan Dinh Street, Hanoi

Factory: Yen Son District, Tuyen Quang Province

Phone / WhatsApp: +84 399 741 589

Email: anna@kosmexgroup.com

You can request:

- Full technical specification sheets: Including density targets, moisture range, phenolic glue details, EN 636-2 / EN 314-2 Bond Class 2 information, and CE2+ documentation where applicable.

- Trial samples for machining and boil-testing: So your engineering team can evaluate cutting, routing, pressing and moisture behaviour directly on your line.

- A configuration recommendation based on your application: Whether you run furniture production, wholesale distribution or formwork projects, Kosmex can point you toward the most suitable setup.

Most European factories make confident sourcing decisions only after seeing how the panels perform under their own conditions. A short trial usually provides all the clarity needed.

FAQ: quick answers for busy EU buyers

Can eucalyptus-core panels really replace birch in furniture production?

In many carcass and structural applications, yes – provided you choose boards with comparable density, good machining behaviour and properly documented glue performance. Phenolic eucalyptus panels aligned with EN 636-2 and EN 314-2 Bond Class 2 can take loads and moisture levels that lighter, cheaper boards cannot handle reliably.

How many reuses can I expect from film-faced panels in formwork?

There is no universal number because reuse depends on edge sealing, stripping technique, concrete mix and storage. However, phenolic-bonded plywood designed for CE2+ structural applications gives you a much better starting point than MR-bonded commercial boards, especially on demanding Eucalyptus plywood for EU market sites.

What is the minimum technical information I should demand?

At minimum, ask for density and moisture ranges, thickness tolerances, EN 636 and EN 314-2 references, glue type and clear statements about recommended and restricted uses. Serious mills always have this on file for their Eucalyptus plywood for EU market ranges and can share it as part of your due-diligence process.

Bình luận