Birch Plywood 2026: Uses, Benefits and Buying Tips

Birch plywood is widely regarded as a premium plywood material in furniture manufacturing, cabinetry, and CNC production. Compared to regular plywood, birch plywood usually comes with a higher price tag, which often raises an important question for buyers: is birch plywood really worth the investment?

This guide explains what birch plywood is, its key properties, density and strength, and how it performs in real world applications. More importantly, it provides practical tips to help you choose the right birch plywood for your project instead of paying for features you may not actually need.

What is Birch Plywood?

Birch Plywood Meaning and Definition

Birch plywood is a type of hardwood plywood made by bonding multiple thin layers of birch wood veneer together with alternating grain directions. This cross layered construction significantly improves strength, stability, and resistance to warping compared to solid wood and low grade plywood.

The term birch plywood generally refers to panels that use birch veneers on the face and back. The core can be made entirely from birch veneers in premium grades or from other hardwood species such as acacia, eucalyptus, or poplar in more economical versions.

Birch plywood is mainly used for interior applications where surface quality, durability, and machining performance are important.

How Birch Plywood is Manufactured

The manufacturing process of birch plywood begins with rotary peeled birch logs that are sliced into thin veneers. These veneers are dried, graded, and then layered so that the grain direction of each layer runs perpendicular to the next.

Adhesive is applied between layers and the panel is pressed under high temperature and pressure. This process creates a stable panel with balanced internal stress.

Depending on the intended use, manufacturers may use moisture resistant glue for interior applications or phenolic glue for environments with higher humidity. Certified birch plywood often meets international standards such as CARB Phase 2, TSCA Title VI, or FSC requirements.

Birch Plywood Texture and Appearance

One of the most attractive features of birch plywood is its clean and consistent appearance. The surface color typically ranges from light cream to pale yellow brown, with a fine and straight grain pattern.

Birch plywood has a smooth texture that requires minimal sanding. This makes it especially suitable for painted finishes, clear coatings, and modern interior designs. Compared to softwood plywood, birch plywood shows fewer knots and visual defects, resulting in a more refined final product.

Birch Plywood Properties Explained

Physical Properties of Birch Plywood

Birch plywood is known for its uniform structure and balanced construction. The multiple thin layers reduce internal stress and help the panel maintain its shape over time.

Key physical properties include good dimensional stability, resistance to twisting, and consistent thickness across the sheet. These characteristics are especially important for furniture production and precision machining.

Birch Plywood Density

Birch plywood density typically ranges from 680 to 760 kilograms per cubic meter, depending on the grade and core structure. This density is higher than that of most softwood plywood, which usually falls between 450 and 550 kilograms per cubic meter.

Higher density contributes to improved strength, better screw holding capacity, and increased resistance to surface damage. However, it also means birch plywood is heavier, which should be considered when handling and transportation are factors.

Birch Plywood Strength and Structural Performance

Many buyers ask how strong birch plywood really is. In practice, birch plywood offers excellent mechanical performance compared to regular plywood.

Its high bending strength allows it to span longer distances without sagging, making it suitable for shelving and cabinet construction. The dense hardwood structure provides strong screw holding, even near panel edges, which is essential for durable joinery.

Birch plywood also performs well under compression and impact, which is why it is commonly used in furniture frames, drawer boxes, and CNC cut components that must retain precise dimensions.

Is Birch Plywood a hardwood or softwood?

Yes, birch plywood is classified as hardwood plywood. Birch trees belong to the hardwood category because they are deciduous species rather than coniferous ones.

In practical terms, this means birch plywood is denser and harder than plywood made from pine or fir. It offers better durability and surface quality, although it is usually more expensive. Compared to other hardwood plywood such as oak or maple, birch provides a balance between strength and cost.

Is Birch Plywood Good?

When Birch Plywood is a Good Choice

Birch plywood is a good choice when surface quality and durability are important. It is commonly used in high end furniture and cabinetry where the plywood edges or faces remain visible.

It is also well suited for CNC machining because of its consistent density and minimal internal voids. Projects that require precise joinery and clean edges benefit greatly from birch plywood.

When Birch Plywood may not be Necessary

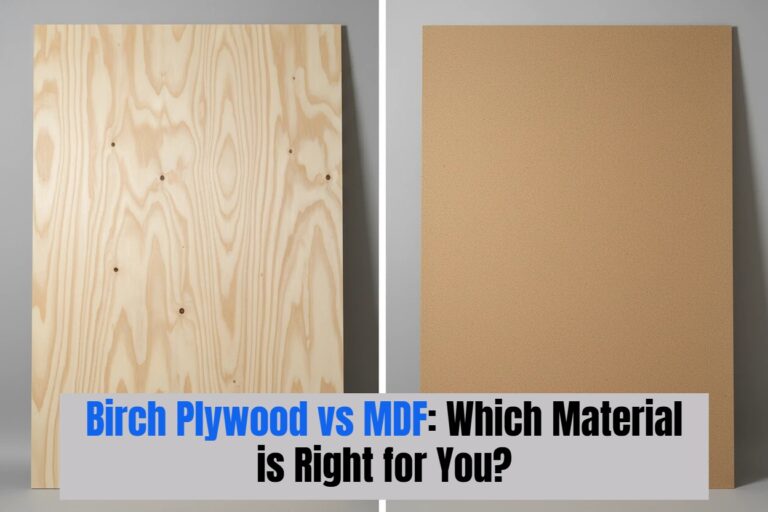

Birch plywood is not always the most cost effective solution. For hidden structural components such as cabinet backs or subfloor layers, regular plywood often performs just as well.

If the surface will be fully painted and appearance is less critical, MDF may provide a smoother finish at a lower cost. For outdoor applications, birch plywood is not recommended unless it is properly sealed and protected from moisture.

What is Birch Plywood Used For?

Furniture Manufacturing

Birch plywood is widely used in furniture manufacturing due to its strength and clean appearance. Common applications include tables, desks, wardrobes, and bookcases.

Its ability to hold screws securely and maintain structural integrity makes it ideal for residential and commercial furniture.

Cabinet and Interior Applications

In cabinetry, birch plywood is often used for cabinet boxes, shelves, and drawer components. The smooth surface accepts paint and veneer well, while the stable structure supports heavy loads such as kitchenware and appliances.

Birch plywood is also used for interior wall panels and built in storage systems.

CNC, Laser Cutting, and Specialty Uses

CNC workshops favor birch plywood because of its predictable machining behavior. It cuts cleanly with minimal tear out and maintains tight tolerances across large panels.

Typical CNC and specialty uses include flat pack furniture, decorative panels, and signage for commercial interiors.

Key Benefits of Birch Plywood

Birch plywood offers several advantages that justify its use in many interior projects. It provides high strength and structural stability, a smooth and attractive surface, and excellent machinability.

It holds fasteners securely, resists warping, and is available in a wide range of thicknesses. When certified, birch plywood can also meet low emission and sustainability requirements for indoor use.

Tips for Choosing the Right Birch Plywood

Choose the Right Grade for Your Application

Higher grades such as B or BB are best for visible furniture surfaces. For structural components that will not be seen, lower grades can reduce costs without sacrificing performance.

Select Proper Thickness Based on Load

Thin panels are suitable for drawer bottoms and cabinet backs, while thicker panels are required for shelving and load bearing furniture. Always match thickness to the expected load.

Check Core Structure Carefully

All birch core plywood offers the highest consistency, but mixed hardwood cores can provide value at a lower cost. Inspect the panel edges to check for gaps or voids.

Consider Moisture Exposure and Glue Type

Interior birch plywood is designed for dry environments. For areas with higher humidity, plywood bonded with phenolic glue offers better resistance to delamination, though it is not fully waterproof.

Verify Certifications and Compliance

Look for certification marks such as CARB Phase 2, TSCA Title VI, or FSC. These indicate compliance with emission standards and responsible sourcing.

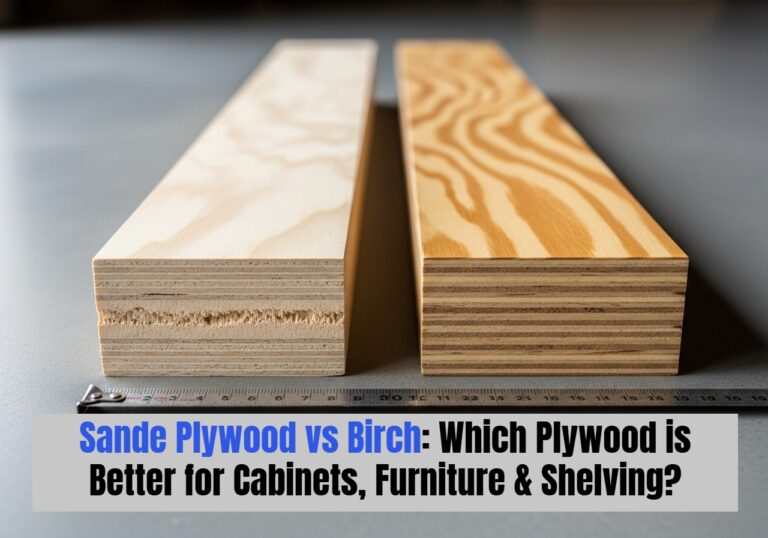

Birch Plywood vs Regular Plywood

Birch plywood differs from regular plywood in material composition, strength, and appearance. It is denser, stronger, and more visually refined, but also heavier and more expensive.

Regular plywood is often sufficient for construction, hidden components, and budget focused projects. The right choice depends on whether appearance, precision, and durability are priorities.

Is Birch Plywood Waterproof?

Birch plywood is not naturally waterproof. Interior grades resist normal indoor humidity but should not be exposed to direct water.

Exterior or marine grade birch plywood uses waterproof glue, but the wood itself can still absorb moisture. Proper sealing of surfaces and edges is essential when moisture exposure is expected.

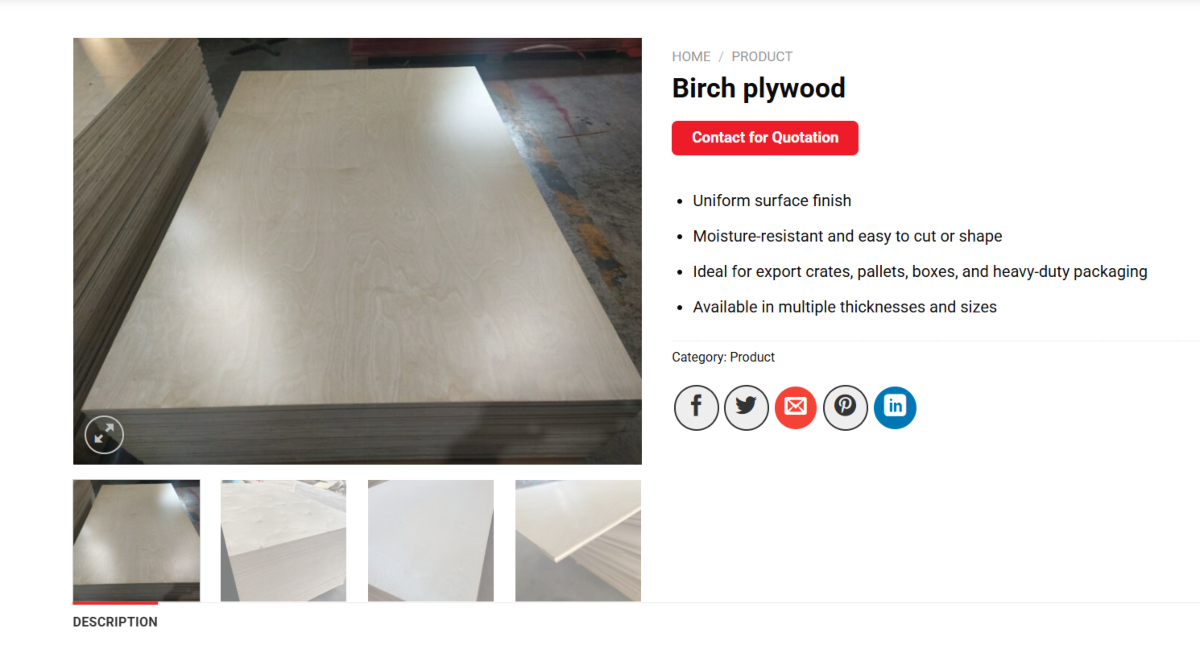

Birch Plywood from Kosemex Vietnam

Kosemex birch plywood is manufactured in Vietnam using responsibly sourced birch veneer and modern plywood production technology. Although birch trees do not naturally grow in Vietnam, Kosemex combines imported birch veneer with strict quality control to deliver panels with consistent thickness, smooth surfaces, and reliable structural performance for international markets.

Designed for furniture, cabinetry, interior panels, and architectural applications, Kosemex birch plywood offers excellent strength and stable multi ply construction, with a fine grain that is easy to paint, stain, or veneer. The product is available in multiple grades and thicknesses, with low formaldehyde emissions, making it a practical and eco friendly choice for professional buyers seeking quality birch plywood from Vietnam.

Visit Kosemex’s birch plywood product page to explore specifications, grades, and ordering options. For detailed information about certifications and quality assurance, check Kosemex’s certificate library and test reports.

Birch Plywood FAQs

What Is So Special About Birch Plywood?

Birch plywood combines strength, smooth surface quality, and consistent structure. These characteristics make it ideal for furniture and precision applications where appearance and durability matter.

Does Birch Grow in Vietnam?

Birch trees do not naturally grow in Vietnam due to the tropical climate. However, many manufacturers produce birch plywood in Vietnam using imported birch veneers combined with locally sourced hardwood cores. Kosemex is a leading producer using this approach to deliver premium birch plywood products.

What Is a Birch Ply?

Birch ply is a shortened term for birch plywood. It refers to plywood panels made with birch veneers and multiple layered construction.

Is Birch Plywood Worth the Price?

Birch plywood is worth the price when its advantages are fully utilized. For visible furniture, cabinetry, and CNC projects, it often provides better long term value than cheaper alternatives.

Conclusion: How to Choose Birch Plywood Wisely

Birch plywood is a high performance material that delivers excellent results when chosen correctly. Its value lies in strength, surface quality, and dimensional stability, not simply in its premium label.

To use birch plywood wisely, match the grade, thickness, and core structure to your actual project requirements. When applied strategically, birch plywood can offer outstanding durability and a professional finish without unnecessary costs.

For sourcing quality birch plywood from a reliable manufacturer, explore Kosemex’s product catalogue or contact their team to discuss your specific needs. Learn more about the company and its commitment to quality at Kosemex Group.

Bình luận