Birch Plywood Phenolic Glue: EN 314-2 Test Explained and Why It Matters

Plywood used in furniture and formwork must deliver reliable bonding strength, moisture resistance and structural stability. That is why EN 314-2 testing is the benchmark for evaluating how well plywood veneers are glued together under demanding conditions. This article explains how the EN 314-2 test works, what Class 1, Class 2 and Class 3 actually mean, and why these ratings matter for manufacturers of sofas, beds, cabinets and concrete formwork.

It also shows how EN 310 bending strength supports real world performance and why Kosmex phenolic glue plywood achieves higher strength, cleaner cores and better durability than many alternatives. With certified test data and export grade production, Kosmex provides dependable plywood for global buyers.

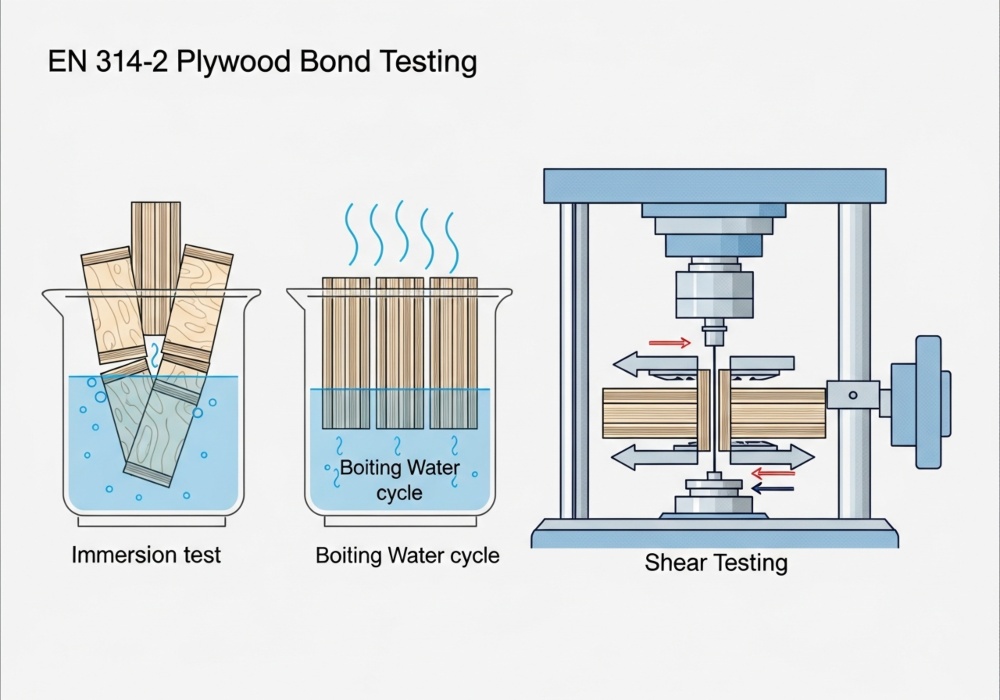

What EN 314-2 actually tests and what the classes mean

EN 314-2 examines the durability of the adhesive bonding between veneers after specific pre treatment cycles that simulate wetting, drying and thermal stress. The testing protocol uses immersion and boiling cycles followed by shear testing of the glue line. The resulting bond classification has three levels.

Class 1 is suitable for dry interior conditions where risk of wetting is negligible. Class 2 covers humid or protected exterior conditions, such as behind cladding or in sheltered outdoor locations. Class 3 is the highest rating and indicates the panel can withstand unprotected exterior exposure, frequent wetting, or long term high humidity exposure. When plywood achieves Class 3, it has passed rigorous immersion and boiling sequences and then retained enough glue joint integrity to meet mechanical strength thresholds.

Meeting EN 314-2 Class 3 is not a guarantee that a panel will survive all outdoor conditions. Proper edge sealing, correct installation, and use of appropriate species for face veneers remain critical. Still, Class 3 identifies phenolic glue plywood whose glue system and manufacturing process deliver exceptional bond durability.

How bending strength and EN 310 relate to real world performance

Bond classification is one axis. Bending strength and modulus, tested under EN 310, are another. EN 310 measures the panel’s modulus of rupture and modulus of elasticity, both parallel and perpendicular to the face grain. Panels with high MOR and MOE values resist deflection and local failure when supporting furniture frames, heavy shelving, or dynamic loads caused by people sitting and shifting.

A phenolic glue plywood panel with Class 3 bonding and high EN 310 bending results is ideal for demanding furniture applications. It will resist sagging, keep fasteners secure, and extend the service life of any structure that depends on it.

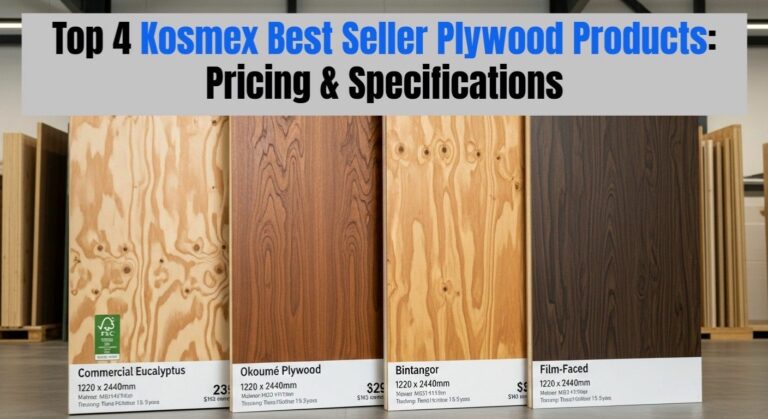

Kosmex high impact phenolic glue plywood advantages in brief

Kosmex manufactures phenolic film faced plywood engineered for export quality applications. Compared to many alternatives, Kosmex panels demonstrate measurable manufacturing and performance advantages.

Key product points are listed here and explained in the next section:

- Core jointed by composer machine for consistent, gap free cores

- Core free of holes and overlaps for uniform mechanical properties

- High density film face veneer at 145 to 180 grams per square meter, eliminating burn marks and surface overlap defects

- High bending strength, compliant with EN 310 strength grading

- Phenolic glue bonding, suitable for Class 3 level performance when required

- FSC and CE certification plus JAS test reports available upon request

Manufacturing differences that create reliable performance

Kosmex achieves its results by controlling core structure, overlay quality and bonding process. Machine jointing of the core veneers eliminates voids, holes and overlaps that create local weak points. A consistent core means shear tests and bending loads distribute evenly across the panel, rather than concentrating at hidden defects.

On the surface the high density phenolic film faced veneer at 145 to 180 grams per square meter creates a durable, non burning surface. Lower density film veneers, commonly 90 to 100 grams per square meter, are more prone to surface defects and reduced abrasion resistance. A high density face reduces finishing work, improves reusability on formwork and makes the panel more resilient where furniture edges receive frequent contact.

The production process for phenolic panels involves longer compression time, higher pressure and careful temperature control. This yields a stronger glue line and increased bonding penetration between phenolic resin and wood. The result is improved bending strength and better long term resistance to wetting and heat exposure.

Lab evidence and real test data

Kosmex testing shows robust bending strength for the phenolic glue plywood sample tested at 12.0 millimeters, seven ply construction. The laboratory report indicates bending strength values of 50.00 megapascals along the face and 43.50 megapascals across the face under JAS 0233-2 structural plywood test conditions. These figures represent high performance that compares favorably to common birch plywood used in premium EU and US markets.

Kosmex provides test certificates from independent laboratories and maintains both FSC and CE certification. These documents are available for export customers who require verifiable quality data for procurement, specification and compliance.

Practical guidance for specifying plywood for furniture and formwork

When specifying plywood for structural or long life applications, consider both bond class and bending strength. For furniture frames such as sofa structures and bed bases, choose panels that meet Class 3 or a high class 2 rating plus elevated EN 310 bending numbers. Where repeated movement, high humidity or direct wetting is possible, always require phenolic bonded panels.

Panel thickness matters. For load bearing components, common thicknesses range from 12 millimeters to 25 millimeters depending on span, fastener spacing and the expected loads. Kosmex produces a full range of high strength panels from 8 millimeters up to 30 millimeters, all manufactured on the same production lines and subject to consistent quality control.

Edge sealing and finishing are essential for exterior use. Even Class 3 panels can degrade at unsealed edges. Specify sealants and recommended installation details to maintain the expected service life.

Comparing phenolic and melamine in real world choice

Phenolic bonded plywood excels where water resistance, heat tolerance and bond longevity matter. Melamine or MUF systems provide cost effective moisture resistant panels for interior furniture and cabinetry. If the application is interior and not load critical, melamine may be acceptable. For export furniture, outdoor seating, industrial tables, formwork and any high stress structure, phenolic bonding is the safer long term selection.

Read more: Phenolic vs Melamine: The Complete Guide for Furniture and Formwork Plywood Buyers

EU buyers section, focused and practical

European importers demand traceable quality and performance. Kosmex phenolic plywood offers the high bending strength and consistent bond quality that EU specifications require. Kosmex panels achieve performance comparable to birch panels but at a competitive price point. Full documentation, including CE marking, FSC certificates and independent test reports to JAS or EN standards, is available for compliance audits and customs clearance.

Stable supply, consistent core quality and reproducible test results are why importers choose phenolic glue plywood from Vietnam when performance and certification matter.

How to evaluate suppliers and what to request

Ask potential suppliers for the following minimal documentation before placing a trial order. Request independent test certificates for EN 314-2 and EN 310 using the exact panel thickness you intend to buy. Verify FSC and CE documents for the production line or mill. Inspect production photos that show core jointing and face film density. Ask for sample panels and conduct your own bending and delamination checks.

Quality control on arrival should include checking for core gaps, veneers with no overlap or holes, and a smooth face with no burning points. For furniture production, trial a sample in your assembly and evaluate fastener holding and edge behavior during routing, drilling and sanding.

Pricing context and value proposition

Phenolic panels cost more than melamine bonded alternatives due to higher resin cost, longer pressing time and often thicker veneers. However, long term value is different. Phenolic bonded panels reduce failure risk, require fewer replacements, and command higher resale or reuse value on projects such as formwork.

Kosmex positions its phenolic glue plywood as a premium commercial product with performance close to birch at lower incremental cost per cubic meter. Typical savings versus imported birch phenolic glue plywood range from 100 to 150 US dollars per cubic meter, while delivering bending properties and bond durability required by demanding markets.

Final recommendations for manufacturers and designers

Specify phenolic glue plywood when you need weight bearing capacity, moisture resistance and long life. For interior decorative elements where loads are low and cost sensitivity is high, consider melamine based panels and validate bond class accordingly. Always insist on independent test data, and match panel thickness to expected loads.

For export buyers, ask for CE, FSC and full lab reports. For OEM furniture manufacturers, request samples in the exact thickness you will use and perform finishing and assembly trials before scaling into production.

How Kosmex supports buyers?

Kosmex offers free samples in requested thicknesses, container quotations for EU, US, Middle East and Southeast Asia markets, and one to one technical consultation for sofa frame, bed frame or cabinet designers. Kosmex provides FSC, CE and independent test reports upon request, and offers technical support to help buyers select the ideal panel for each application.

Closing summary

EN 314-2 testing defines bond quality in a way that directly correlates to field performance. Phenolic glue, combined with consistent machine jointed cores and high density film face veneers, produces plywood that resists delamination, carries heavy loads and endures humid or wet environments.

Kosmex high impact phenolic glue plywood demonstrates these properties with independent lab results, industry certification and production practices that reduce defects and variability.

Bình luận