Subtotal: 0 ₫

What Is Anti Slip Film Faced Plywood (Wiremesh Plywood)? Structure, Usage & EU Buyer Checklist

If you’re sourcing panels for truck flooring, trailer decks, scaffolding planks, or industrial walkways, the requirement is usually the same: more grip, more wear resistance, and stable bonding in wet conditions. That’s exactly what anti slip film faced plywood (also called wiremesh plywood or non-slip film faced plywood) is built for.

This guide explains what anti slip film faced plywood is, how it’s constructed, where each surface pattern fits best, and how EU-focused buyers (procurement + QA) can approve a supplier faster using standards, independent test reports, and clear specification language.

Definition: what is anti slip film faced plywood?

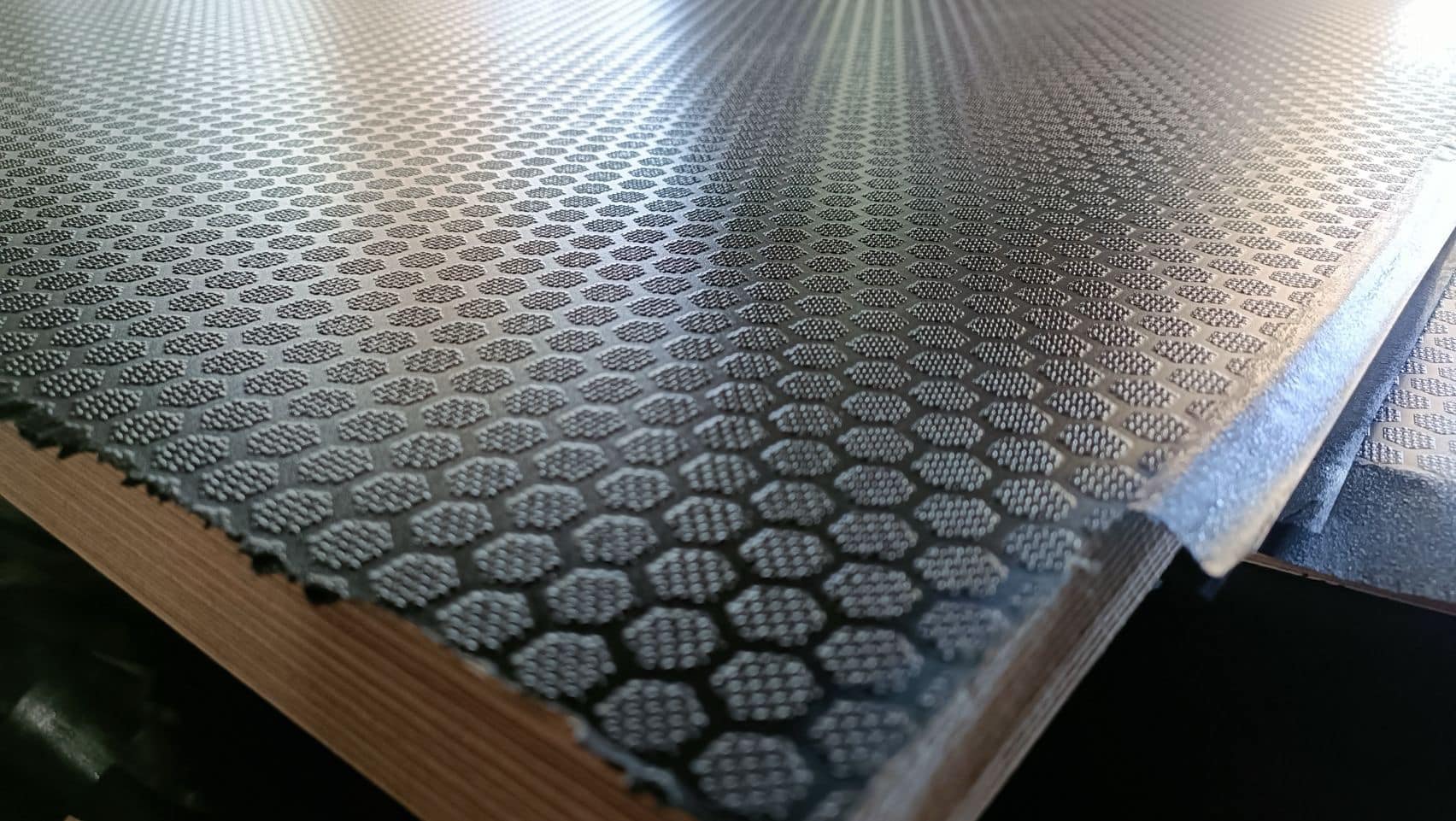

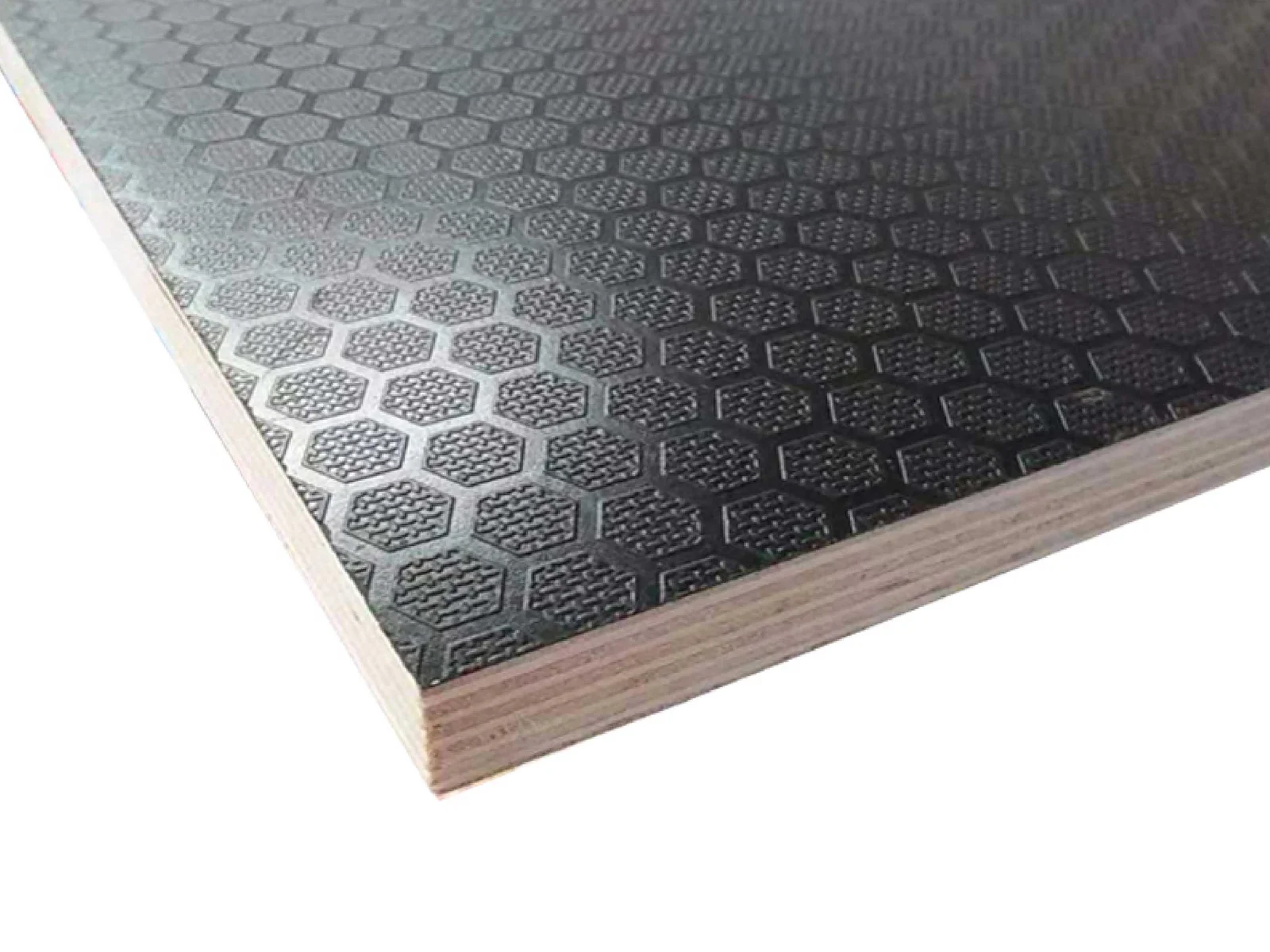

Anti slip film faced plywood is a plywood panel laminated with a resin-impregnated film. One face is embossed for traction (wiremesh, rice, hexagon), while the other may remain smooth for cleaning or installation convenience.

Kosmex describes its anti-slip panel as a phenolic-film-coated plywood with one smooth face and one “wiremesh / patterned” face — ideal for heavy-duty environments such as trailers, containers, ramps, and scaffolding floors.

If you also need standard plywood options for formwork or non-textured applications, you can compare it with Kosmex’s general Film Faced Plywood catalogue.

Why choose anti slip film faced plywood instead of basic plywood?

When safety and durability matter, anti slip film faced plywood is a clear upgrade over basic plywood or painted floors — especially in environments where surfaces get wet, dusty, or contaminated with oil and mud. Plain plywood becomes slippery very quickly, and paint coatings tend to wear off under traffic.

With anti slip film faced plywood, the textured phenolic film is pressed onto the surface under heat and pressure, creating a durable, three-dimensional pattern. This gives you long-lasting traction and allows slip performance to be measured in a laboratory, rather than guessed on site. That’s crucial for buyers who must demonstrate compliance and control of safety risks.

From a lifecycle perspective, anti-slip panels usually save cost over time. The film surface resists abrasion and moisture, so the floor can stay in service for more loading cycles before replacement. For truck floors, container decks, ramps and scaffolding boards, this often means fewer shutdowns, fewer damaged panels, and fewer slip incidents across the life of the project.

Construction (structure) — what actually creates grip and durability?

To evaluate anti slip film faced plywood like a real buyer, look at 5 performance “layers”:

A) Core (strength + screw holding)

Kosmex uses high-quality hardwood cores (e.g. mixed hardwoods) to ensure strength, load capacity, and good screw/nail holding — essential for truck floors, container decks, and repeated loading/unloading cycles.

B) Glue line (bonding class)

For demanding environments, you’ll typically see WBP systems. Kosmex uses phenolic and melamine-based adhesive systems (MUF/PF) suitable for exterior and humid conditions. EU buyers often reference EN 314-2 bonding classes when defining the required glue line performance.

C) Film overlay (surface wear & moisture barrier)

Kosmex specifies phenolic films in the 120–240 g/m² range depending on product and program. Heavier films generally provide better abrasion resistance and longer service life. In the anti-slip line, the technical sheet shows surface types such as FF, FW (pattern rice / hexagon) with 220 g/m² film.

D) Embossed pattern (traction)

Grip comes from the embossed film texture — this is the classic “wiremesh” effect. On the Kosmex product page, the surface is described as Smooth / Anti-slip (wire mesh). Other emboss options (rice, hexagon) are available for different traction and cleaning requirements.

E) Edge sealing (longevity)

Edges are a common failure point in any plywood flooring system. Kosmex seals panel edges with waterproof paint to reduce water penetration — critical for flooring panels that see impact damage, washing, and repeated wet/dry cycles.

Independent test results: anti-slip index & abrasion resistance

Kosmex doesn’t just claim performance — the panels are backed by independent laboratory testing.

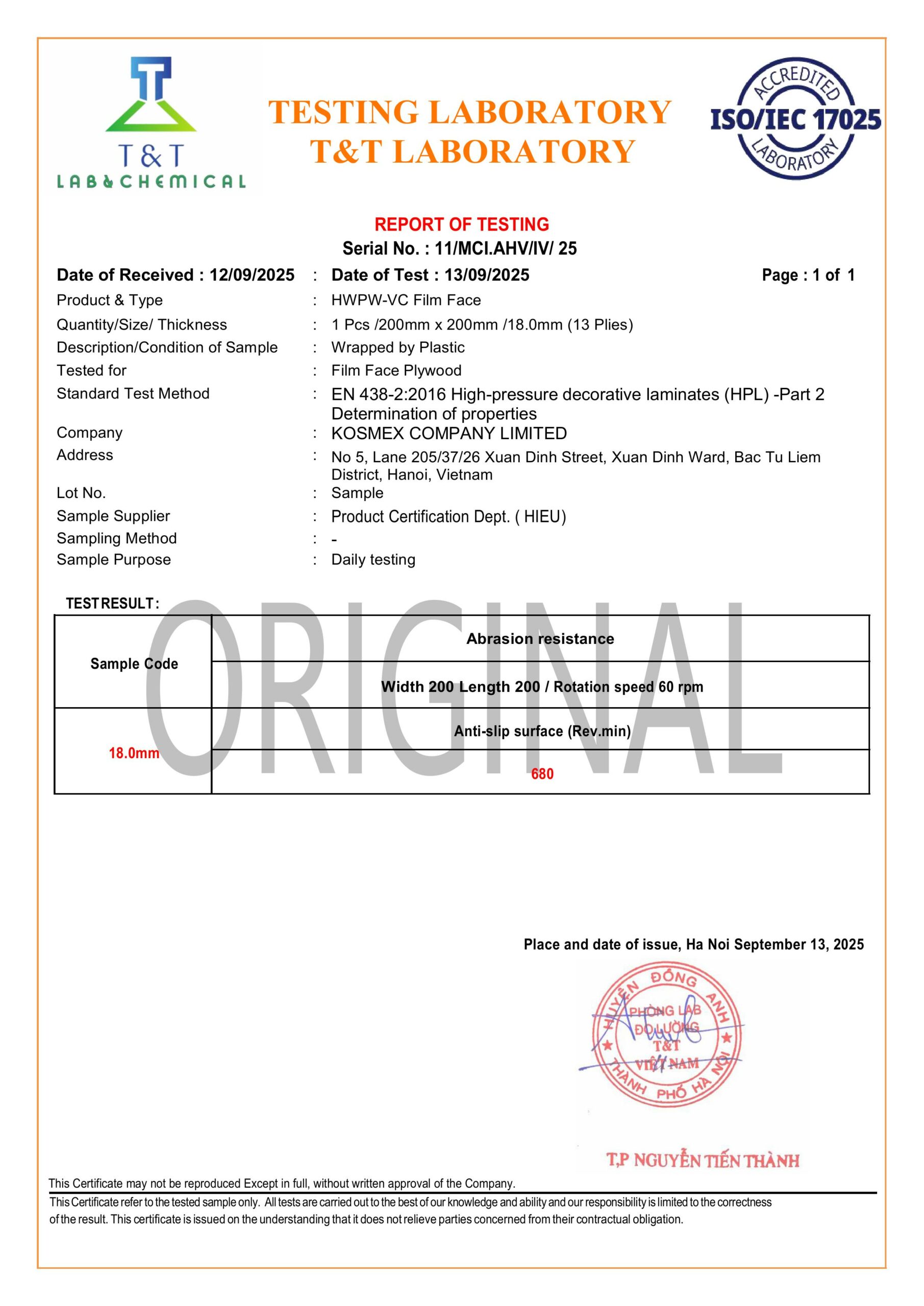

Taber abrasion resistance (EN 438-2:2016)

A sample of Kosmex anti-slip film faced plywood (HWPW-VC film face, 18 mm, 13 plies, 200 × 200 mm, anti-slip surface) was tested at T&T Laboratory using EN 438-2:2016 (High-pressure decorative laminates – Part 2, determination of properties).

Under standard Taber abrasion test conditions (60 rpm, defined load), the anti-slip surface reached 680 revolutions before reaching the specified end point.

For buyers, this gives a concrete, numerical indication that the surface is engineered to withstand substantial wear from traffic, pallets, or equipment before the texture is significantly degraded.

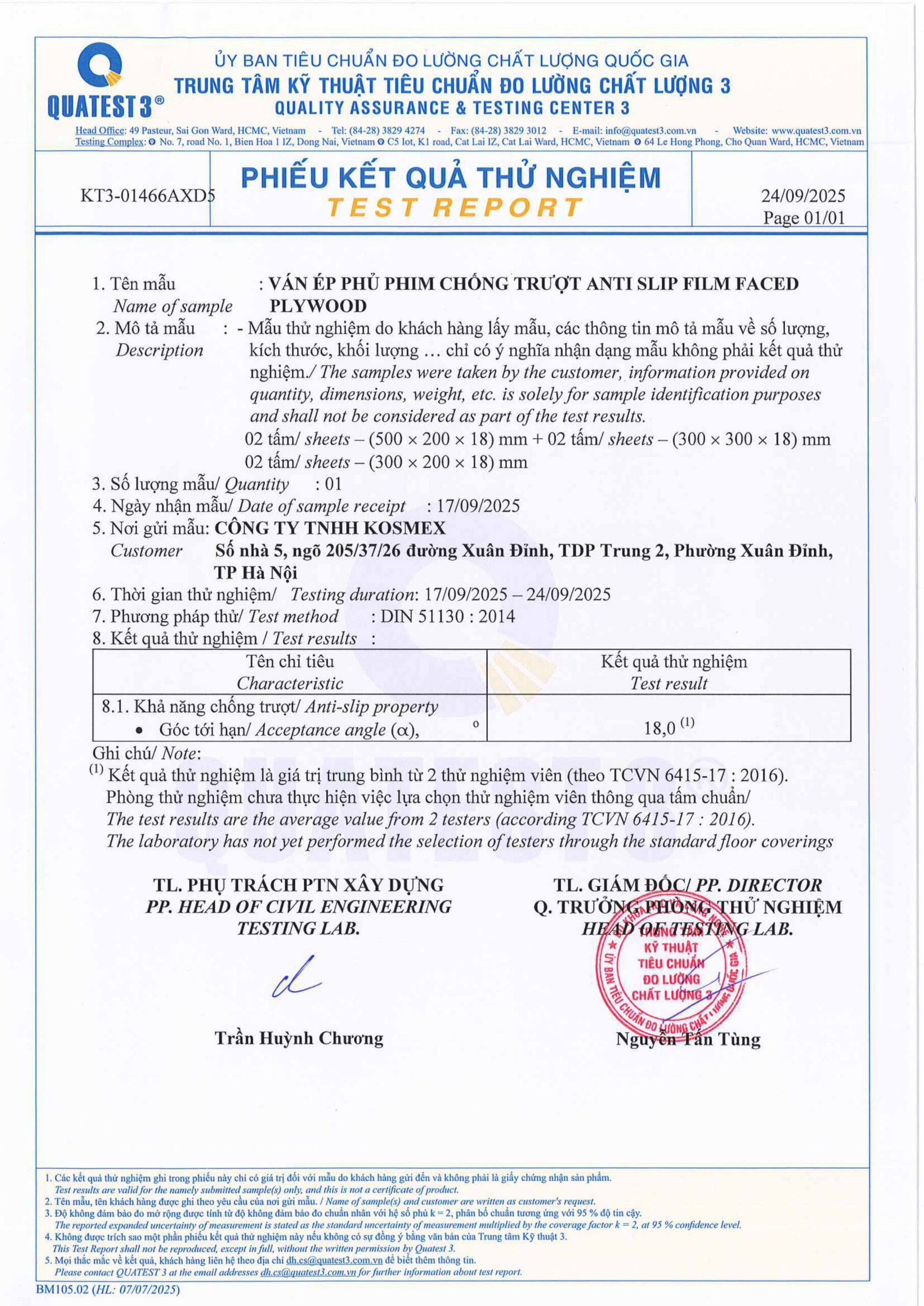

Anti-slip property — DIN 51130:2014 ramp test

A separate sample from Kosmex was tested in a civil engineering testing laboratory using DIN 51130:2014, the classic ramp test for slip resistance of floor coverings.

The report records an acceptance angle (α) of 18.0° for the anti-slip surface.

In practical terms, this means the test person could walk safely up to that inclination on a lubricated ramp before slipping. This angle is typically used by QA teams and safety engineers to compare anti-slip performance between alternative materials and to check against internal or regulatory requirements.

Together, these two certificates give procurement and QA teams lab-verified evidence of both surface durability (680 Taber cycles) and slip performance (18° acceptance angle) for Kosmex anti slip film faced plywood — not just marketing claims.

Patterns: wiremesh vs rice vs hexagon (how to choose)

Many buyers casually call everything “wiremesh plywood”, but in practice you’re choosing a surface geometry for your application:

- Wiremesh (mesh) pattern – a general-purpose anti-slip texture for work platforms and transport floors. Good all-round grip and very familiar to installers.

- Rice pattern – combines traction with easier cleaning, often preferred where regular wash-down is required (logistics hubs, container floors, light-industrial walkways).

- Hexagon pattern – gives a strong “bite” underfoot, commonly used in high-traffic loading zones, ramps, and heavy-duty vehicle flooring.

Kosmex’s technical sheet explicitly lists pattern rice / hexagon in the anti-slip product line, alongside the smooth / wiremesh options. This allows you to match surface texture to risk level, cleaning regime, and customer expectations.

Where anti slip film faced plywood is used (high-intent applications)

Kosmex positions its anti-slip film faced plywood for:

- Truck and trailer flooring

- Container flooring

- Scaffolding platforms and construction walkways

- Loading ramps and dock boards

- Stage systems and temporary outdoor platforms

These are exactly the environments where slip incidents, abrasion, and moisture cycling are common — and where anti slip film faced plywood typically outperforms basic plywood plus paint or simple non-textured panels.

EU buyer checklist (specs + standards + tests you can ask for)

A) Standards (language procurement understands)

Kosmex references EN 636 (plywood for general use – classification by service conditions) and EN 314-2 (bond quality requirements) for this product range. These are common reference points for European buyers when they assess whether a plywood panel is suited for dry, humid, or exterior use and what bonding performance is expected.

B) Slip resistance: “R” rating (R10/R11)

From the DIN 51130:2014 ramp test report, Kosmex can provide a measured acceptance angle of 18.0° for the anti-slip surface.

Include this value in your internal risk assessment or in specifications where slip resistance criteria must be documented.

C) Abrasion resistance (surface wear)

Use Kosmex’s Taber abrasion test report to document surface durability: 680 revolutions for the anti-slip surface according to EN 438-2:2016.

This number is useful when comparing alternative products or when your internal standard requires a minimum number of rotations.

D) Mechanical performance (strength/stiffness)

KOSMEX provides EN 310-based values on the technical sheet, including for the anti-slip line:

-

Bending strength (length): 50 N/mm²

-

MOE (length): 5000 N/mm²

E) Practical production tolerances (important for installers)

Their technical sheet lists:

-

Length/width tolerance ±1mm (EN 315:2000)

-

Thickness tolerance ±0.5mm (EN 315:2000)

These are important for installers who need panels to “drop in” without excessive trimming or gaps.

F) Common sizes & thickness (buyer-ready)

KOSMEX lists:

-

Thickness: 9–21mm

-

Size: 1220×2440mm / 1250×2500mm

You can start from these as standard, then specify any project-specific sizes or machining if required.

Quick selection guide (use-case → recommended spec)

Use this to speed up RFQs for anti slip film faced plywood:

-

Truck/trailer flooring: hexagon or wiremesh; prioritize abrasion + slip rating

-

Container flooring / ramps: hexagon; prioritize edge sealing + consistent tolerances

-

Scaffolding / walkways: wiremesh; prioritize bonding class + moisture control

-

Stages / temporary outdoor platforms: rice or hexagon; balance grip with cleaning needs

(Then confirm thickness, glue system, and film weight based on the load and span.)

Conclusion

If your EU customer needs a safer, longer-lasting floor panel, anti slip film faced plywood is a proven choice — especially when you can supply independent test reports for slip resistance and abrasion together with EN-based specifications.

Kosmex supports you with:

- DIN 51130:2014 anti-slip test report (acceptance angle 18.0°)

- EN 438-2:2016 Taber abrasion report (680 revolutions)

- EN 636 / EN 314-2 structural and bonding references

- Size, thickness, and pattern options tailored to truck, container, ramp, and scaffolding programs

Request quotation + technical sheet + test pack from KOSMEX:

- Company: KOSMEX CO., LTD.

- Phone / WhatsApp: 0399 741 589

- Email: anna@kosmexgroup.com | anna.kosmex@gmail.com

- Office: House No. 5, Lane 205/37/26, Xuan Dinh Street, Trung 2 Residential Area, Xuan Dinh Ward, Hanoi City

When contacting Kosmex, include your target application, size, thickness, surface pattern (hexagon / rice / wiremesh), glue system, and any required slip/abrasion criteria so the team can quickly propose the best-matching anti slip film faced plywood and attach the relevant test reports.

FAQ

1) Is wiremesh plywood the same as anti-slip plywood?

Wiremesh refers to the embossed anti-slip surface. In most supplier catalogs, it’s a type of anti slip film faced plywood.

2) What patterns does Kosmex supply?

KOSMEX lists pattern rice/hexagon for the anti-slip line, plus smooth/anti-slip (wiremesh) surface options.

3) What does R10/R11 mean?

They are DIN ramp-test slip classes; commonly cited ranges are R10 (10–19°) and R11 (19–27°).

4) What abrasion performance can I request?

KOSMEX states 680 rotations from a Taber abrasion test referenced to EN 438-2 (for the anti-slip line).

5) Which standards matter most for EU approval?

Buyers commonly reference EN 636 (use class) and EN 314-2 (bond quality).

Anti slip film faced plywood (Hexagon/Pattern Rice)

Anti slip film faced plywood (Hexagon/Pattern Rice)

Bình luận