What is CDX Plywood: Uses, Benefits & Maintenance

CDX plywood is one of the most widely used building materials in construction, yet many builders and DIY enthusiasts don’t fully understand what makes it distinct or how to maximize its potential. This comprehensive guide explains everything you need to know about CDX plywood: from its meaning and manufacturing process to its best applications, proper maintenance, and suitable alternatives.

What is CDX Plywood

CDX Plywood Meaning

CDX plywood is a type of construction-grade plywood manufactured with an exterior-grade adhesive that provides moisture resistance suitable for outdoor and structural applications. The term “CDX” breaks down into specific components that define the material’s characteristics:

C Grade: Refers to the plywood’s face veneer quality. The C-grade veneer on the front allows visible knots and repairs up to 1 1/2 inches in diameter, making it suitable for applications where appearance is less critical than functionality.

D Grade: Describes the back veneer quality, which has even more knots and defects than the C-grade. This lower-quality backing reduces cost while maintaining structural integrity where it’s needed.

X Grade: Stands for “exterior-grade adhesive” (phenol-formaldehyde or phenolic resin glue). This exterior-grade glue is the critical differentiator, making CDX plywood resistant to moisture and suitable for outdoor exposure. The “X” designation indicates the plywood can withstand exposure to weather, humidity, and moisture without the adhesive failing.

The Difference Between CDX and Regular Plywood

Regular plywood (typically BC or AC grade) uses interior-grade adhesives that break down when exposed to moisture. CDX plywood differs fundamentally in three ways:

Moisture Resistance: CDX’s exterior-grade adhesive prevents delamination (layers separating) when exposed to moisture, rain, and humidity. Regular plywood’s interior adhesive fails under prolonged moisture exposure, causing the veneer layers to separate and weakening the panel.

Durability in Outdoor Conditions: CDX plywood maintains structural integrity in wet environments and outdoor applications. Regular plywood deteriorates quickly outdoors, making it unsuitable for roofing, exterior sheathing, or ground-level applications where moisture contact is likely.

Cost and Application Focus: CDX plywood is engineered for temporary and permanent outdoor use, making it ideal for construction projects. Regular plywood works best for indoor furniture, cabinetry, and protected interior applications where moisture exposure is minimal.

Veneer Grade Implications: CDX’s C and D grade veneers tolerate surface defects because appearance matters less than weather-resistance. Regular plywood’s higher veneer grades (A, B, C) prioritize aesthetic appearance for visible applications like cabinetry and interior design.

Benefits of CDX Plywood

CDX plywood offers multiple advantages that make it a preferred choice for construction professionals and serious DIYers:

Cost-Effective Option

CDX plywood provides exceptional value for construction projects. The combination of lower-grade veneers (C and D) with exterior adhesive creates affordability without sacrificing weather-resistance.

For large projects requiring substantial sheathing or structural components, CDX’s lower cost per sheet significantly reduces material expenses. Budget-conscious builders can specify CDX knowing they’re getting moisture-resistant performance at economy pricing.

Versatility

CDX plywood adapts to numerous applications across residential and commercial construction. Whether you need roof decking, exterior wall sheathing, concrete formwork, or temporary structural bracing, CDX delivers adequate performance. This versatility reduces the need to stock multiple plywood grades, simplifying procurement and inventory management. Builders can specify one material for diverse applications throughout a project.

Accessibility

CDX plywood is readily available at virtually every building supply store, lumber yard, and home improvement retailer. This widespread availability means consistent supply and competitive pricing due to market competition. You can find CDX sheets in standard sizes (4×8 feet being most common) and multiple thicknesses from 3/8 inch to 3/4 inch, making it simple to source exactly what you need without special orders or delays.

Strength and Stability

The cross-grain layup (each veneer layer grain perpendicular to adjacent layers) creates exceptional strength in both directions. This multi-directional strength makes CDX excellent for structural applications like roof trusses, floor joists, and wall sheathing where loads come from multiple directions. The gluing process bonds veneers so thoroughly that CDX panels resist warping and twisting even under stress.

Moisture Resistance

While not waterproof, CDX plywood’s exterior-grade adhesive resists moisture penetration better than interior plywood. The glue maintains its integrity when exposed to damp conditions, rain, and humid environments, preventing delamination that weakens standard plywood. However, the veneer itself can absorb moisture, so protective coatings remain important for long-term durability.

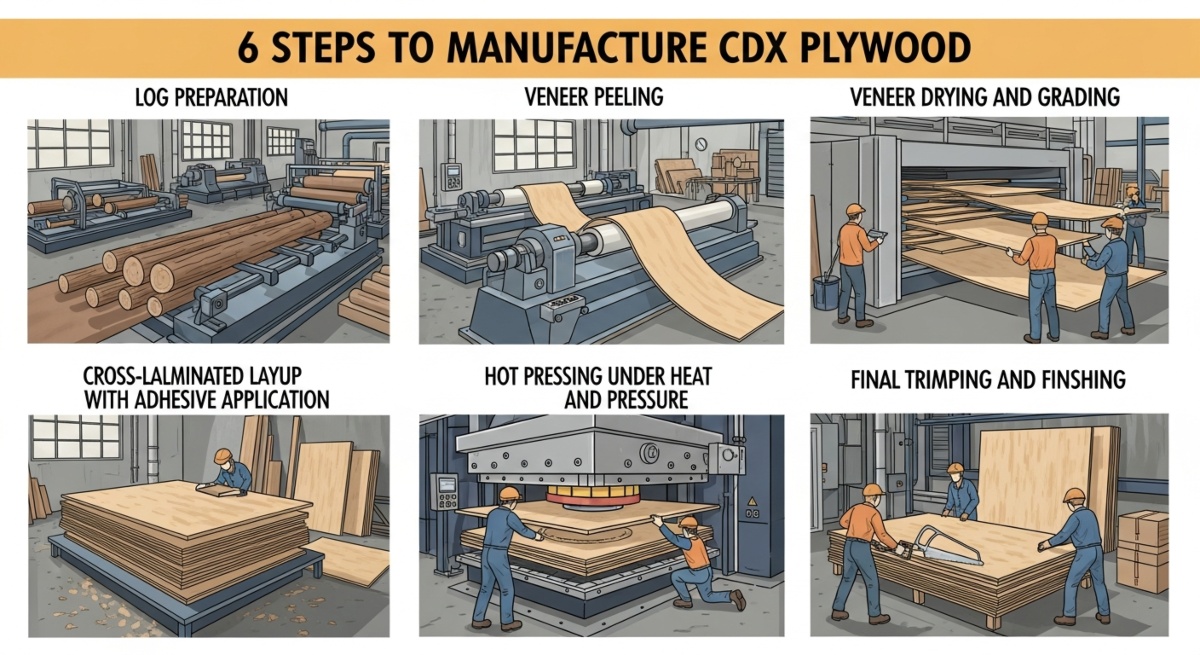

6 Steps to Manufacture CDX Plywood

Understanding how CDX plywood is manufactured reveals why it performs so well in challenging conditions. The manufacturing process involves precise control of materials, equipment, and timing:

Step 1: Log Preparation

Manufacturing begins with raw logs delivered to the mill. Workers debark logs by removing the outer bark, then soften the logs in hot water or steam chambers. This softening process makes the wood pliable and easier to peel without splintering. Hot logs are more uniform in properties, ensuring consistent results throughout the manufacturing process. Temperature-controlled soaking chambers maintain precise conditions for optimal peeling.

Step 2: Veneer Peeling

Softened logs mount on a lathe where a sharp blade continuously peels paper-thin veneers from the rotating log, similar to unrolling paper towels. This continuous veneer peeling maximizes yield from each log. The lathe operator controls thickness (typically 1-4mm) to create veneers with consistent properties. A single log can yield continuous veneer hundreds of feet long, which is then cut into manageable sections.

Step 3: Drying and Grading

Fresh veneers contain high moisture content that must be reduced to achieve proper bonding. Industrial kilns dry veneers to precise moisture content levels (typically 5-15%). As veneers dry, quality inspectors grade them according to standards: higher-quality veneers designated for the C-grade face, lower-quality veneers (with more knots and defects) sorted for D-grade backing and inner layers. Grading ensures appropriate veneers reach the surface where visibility matters.

Step 4: Layup and Gluing

Workers stack dried veneers with grain directions perpendicular between layers; this cross-grain orientation creates the multi-directional strength that makes plywood superior to solid wood. Exterior-grade phenolic adhesive (the critical “X” in CDX) is applied between veneer layers, typically with specialized spray equipment ensuring even coverage. The precise glue application is critical; too little results in weak bonds, too much wastes material and extends processing time.

Step 5: Hot Pressing

The glue-coated veneer stack enters massive hydraulic presses exerting tremendous heat (around 350-400°F) and pressure (up to 400-600 psi). This simultaneous heat and pressure activates the phenolic adhesive, causing it to cure and permanently bond veneer layers into solid panels. Pressing time is precisely controlled typically 5-15 minutes to ensure complete adhesive cure. Temperature and pressure consistency is critical; variations produce weak or improperly bonded panels.

Step 6: Finishing

After hot pressing, panels exit the press and cool. Industrial saws trim panels to standard dimensions (typically 4 feet by 8 feet). Sanding equipment creates consistent smooth surfaces on both sides. Final inspection checks for delamination, structural defects, and manufacturing flaws. Quality control technicians mark substandard panels for downgrading or rejection. Acceptable panels are stacked, wrapped, and prepared for shipment to distributors and retailers.

4 Best Applications of CDX Plywood

CDX plywood’s moisture resistance and affordability make it ideal for specific construction applications:

Exterior Wall Sheathing

CDX plywood serves as the structural layer behind siding on exterior walls. Its exterior-grade adhesive withstands weather exposure during construction before siding installation. The cross-grain veneer structure provides excellent racking resistance (resistance to lateral forces that can distort wall frames). Builders can safely specify CDX knowing it will maintain integrity through weather exposure and the construction process.

Roof Decking and Sheathing

Roof applications demand exceptional moisture resistance since rain and snow melt continuously expose the material. CDX’s phenolic adhesive prevents delamination even when repeatedly wet and dry. The smooth surface provides good nailing and fastening for shingles or metal roofing. Roof-grade CDX is engineered specifically to handle these challenging conditions while supporting foot traffic during installation and maintenance.

Concrete Formwork

Construction crews use CDX plywood to create temporary forms for pouring concrete foundations, walls, and slabs. The smooth face accepts concrete well, creating clean concrete surfaces. CDX withstands concrete moisture exposure during the curing process without delaminating. The cross-grain structure provides excellent strength for supporting concrete’s weight. After concrete cures, forms are stripped away and plywood can be reused for subsequent pours.

Structural Components

CDX plywood works for structural applications like rim board, blocking, and bracing where load-bearing capacity matters. The cross-grain construction provides strength equal to dimensional lumber while allowing flexibility in sizing and cutting to fit specific applications. Engineers often specify CDX for structural components in buildings where temporary or permanent weather exposure occurs.

4 Common Sizes of CDX Plywood

CDX plywood comes in standard dimensions designed for typical construction applications:

3/4 CDX Plywood

The 3/4-inch thickness (3/4″) is the most common CDX size for structural applications. This thickness provides excellent strength for roof decking, floor sheathing, and wall bracing. The 3/4-inch dimension accommodates standard fastening patterns and provides adequate material for nailing without splitting. Most building codes specify 3/4-inch minimum for roof and floor applications. This thickness has the highest monthly search volume, indicating it’s the preferred choice for serious construction projects.

Typical Applications: Roof sheathing, floor underlayment, concrete formwork, structural bracing

1/2 CDX Plywood

The 1/2-inch thickness suits lighter-duty applications and projects where weight matters. This thinner option costs less per sheet than 3/4-inch while providing adequate strength for wall sheathing, underlayment in non-structural applications, and temporary bracing. The reduced weight makes handling easier and speeds installation. Building codes typically allow 1/2-inch for wall applications in appropriate stud spacing configurations.

Typical Applications: Wall sheathing, temporary bracing, non-structural underlayment, lighter-duty applications

5/8 CDX Plywood

The 5/8-inch thickness provides a middle ground between 1/2-inch and 3/4-inch options. This size isn’t as universally common as the two above but serves specific applications where the thin 1/2-inch lacks adequate strength but 3/4-inch overkill seems wasteful. Some builders prefer 5/8-inch for specialized applications requiring intermediate strength.

Typical Applications: Specialty structural applications, specific underlayment requirements, engineered applications

4×8 CDX Plywood

The standard 4 feet by 8 feet dimension is the predominant sheet size in North American construction. This size evolved because it efficiently covers wall heights (standard 8-foot walls) while remaining manageable for workers to handle and transport. A 4×8 sheet covers 32 square feet, making material quantity calculations straightforward. This standardization means maximum availability, competitive pricing, and optimal waste minimization in typical construction layouts.

Typical Applications: All standard CDX applications use 4×8 dimensions by default

How to Choose the Right CDX Plywood

Selecting appropriate CDX plywood for your project requires considering several factors:

Selecting Thickness

Begin by determining your project’s structural requirements. Roof and floor applications typically demand 3/4-inch thickness to meet building codes and provide adequate support. Wall sheathing usually allows 1/2-inch, reducing cost while meeting strength requirements. Check your local building code for minimum thicknesses in your climate; areas with heavy snow loads or high winds may require thicker material. Consider future loads: if you’ll be walking on the surface during installation or maintenance, thicker material reduces deflection and feels more stable.

Conservative selection means choosing thicker material when in doubt. The cost difference between 1/2-inch and 3/4-inch is modest compared to the expense of replacing or reinforcing inadequate sheathing later. Opting for thickness provides safety margin and extends service life.

Inspecting for Defects

Before purchasing, examine plywood sheets for damage and defects. While CDX allows visible knots and repairs, severe defects compromise function. Check for:

- Delamination: Separated veneer layers indicating manufacturing defects or water damage. Reject any sheet showing delamination it signals adhesive failure.

- Large knots or Voids: Knots larger than expected for the grade indicate lower quality. Voids (missing veneer areas) weaken the panel.

- Warping or Cupping: Twisted or cupped sheets won’t lay flat, creating installation problems and potential structural issues.

- Edge Damage: Chipped or crushed edges from rough handling indicate potential internal damage.

- Water Damage: Swollen or discolored areas suggest moisture exposure. Reject any sheet with visible water damage.

Request sheets from the front of pallets where they’ve had less exposure and handling. Inspect several sheets; the first and last sheets on a pallet often show the most damage.

Environmental Considerations

CDX plywood manufacturing involves phenolic adhesives and chemical processing. If environmental impact concerns you, research manufacturers’ sustainability practices. Some mills use certified sustainable forestry practices or salvage small-diameter trees that would otherwise be waste. Consider that CDX’s durability means longer service life, reducing replacement needs and overall environmental impact compared to less durable alternatives.

For interior applications (unusual for CDX but possible), ensure any plywood used indoors offgasses acceptably. Most CDX plywood has low VOC (volatile organic compound) emissions when properly cured, but verify for sensitive applications or environments with air quality concerns.

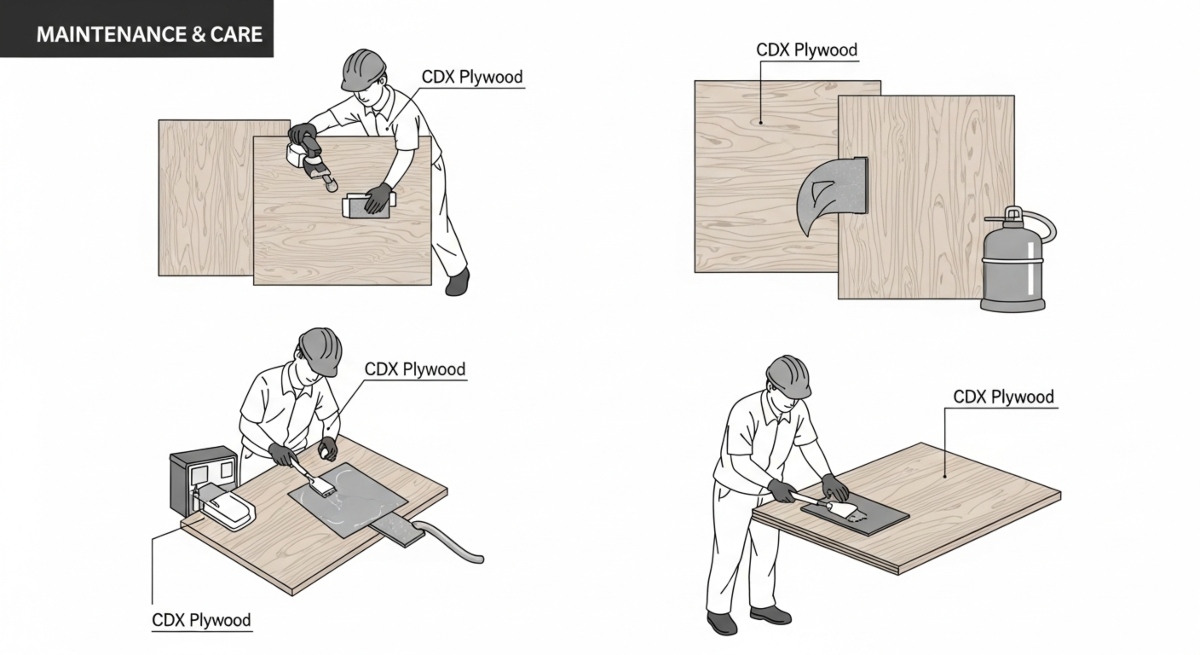

4 tips for Maintenance and Care of CDX Plywood

Proper maintenance extends CDX plywood’s service life and preserves its structural integrity:

Protection and Sealing

Seal All Edges: Plywood edges are most vulnerable to moisture infiltration since cross-grain exposure allows water absorption directly into the veneer layers. Apply paintable sealant, caulk, or paint to all edges, especially cut edges created during installation. This simple step dramatically extends plywood life by blocking the primary moisture entry point.

Apply Weather-Resistant Finishes: For outdoor applications, use exterior-grade paint, stain, or sealant to protect the face and back. Proper finishes block UV rays that degrade wood and fade color, plus they provide water-resistant barriers. Paint or stain penetration creates a protective layer above the plywood surface.

Reapply Finishes Regularly: Exterior finishes degrade over time through UV exposure, weathering, and normal wear. Recoat every 3-5 years (or as recommended by finish manufacturer) to maintain protection. Regular recoating prevents deterioration that, once started, accelerates quickly.

Cleaning and Minor Repairs

Regular Dusting: Use a soft cloth or broom to remove dust and debris that traps moisture and promotes mold growth. Regular cleaning prevents the accumulation that leads to deterioration.

Clean with Mild Solutions: Wash surfaces with mild soap and water using soft brushes. Avoid abrasive cleaners or pressure washers that damage the finish and open the surface to moisture infiltration. Pressure washing forces water into wood fiber and potentially under finishes.

Repair Small Damage: Fill cracks and small gouges with quality wood filler matched to the wood color. Sand smooth once dry, then touch up finish to match. Small repairs prevent damage from expanding, water entering cracks leads to rot and structural failure.

Installation and Environmental Management

Allow Expansion Gaps: Leave approximately 1/8-inch gaps between plywood sheets and between sheets and structural members. This allows for minor wood movement due to moisture and temperature changes without creating destructive stresses.

Minimize Direct Sunlight: Excessive UV exposure fades and degrades finishes. If possible, position applications to reduce direct sun, or use UV-protective finishes designed for high-sun environments.

Handle Carefully: Lift plywood rather than dragging it. Dragging creates dents, abrasions, and potential delamination damage that becomes failure points.

Inspection and Replacement

Inspect Regularly: Check plywood periodically for signs of warping, rot, delamination, or structural failure. Early detection allows remedial action before catastrophic failure.

Address Issues Promptly: Don’t delay repairs. Water infiltration progresses rapidly once started. A small delamination becomes structural failure if ignored.

Replace Severely Damaged Sections: When damage is extensive, replacing the affected section is often more economical and safer than attempting repairs. Structural integrity can’t be compromised in critical applications.

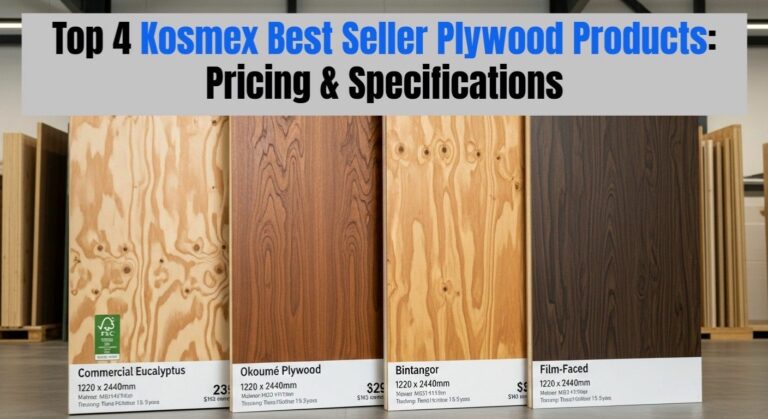

3 Best Alternatives to CDX Plywood

Depending on your specific application and requirements, several alternatives to CDX plywood may be more suitable:

For Structural and Exterior Use

Oriented Strand Board (OSB)

OSB is highly popular and significantly cheaper than CDX plywood, making it attractive for budget-conscious projects. OSB offers comparable strength through its engineered strand orientation. However, OSB has notable disadvantages: it absorbs water more readily than plywood and dries more slowly once wet. For temporary applications or dry environments, OSB works well. For permanent outdoor exposure or applications where quick drying after rain is critical, CDX’s superior moisture behavior makes it preferable despite higher cost.

Pressure-Treated Plywood

Pressure treatment infuses wood with chemical preservatives that provide superior moisture and rot resistance. Pressure-treated plywood excels for ground-contact applications, permanent outdoor structures, and high-moisture environments.

The chemical treatment provides longer service life than CDX in these harsh conditions. However, pressure-treated plywood costs significantly more and the chemicals require careful handling and proper PPE during installation.

Marine Plywood

Marine plywood represents the premium alternative for high-moisture applications. Marine-grade veneers have minimal voids, premium exterior adhesive, and sometimes additional protective treatments. Marine plywood withstands constant moisture, high humidity, and saltwater exposure better than CDX. It’s ideal for permanent outdoor structures requiring maximum durability. The significantly higher cost limits use to applications where longevity justifies the investment.

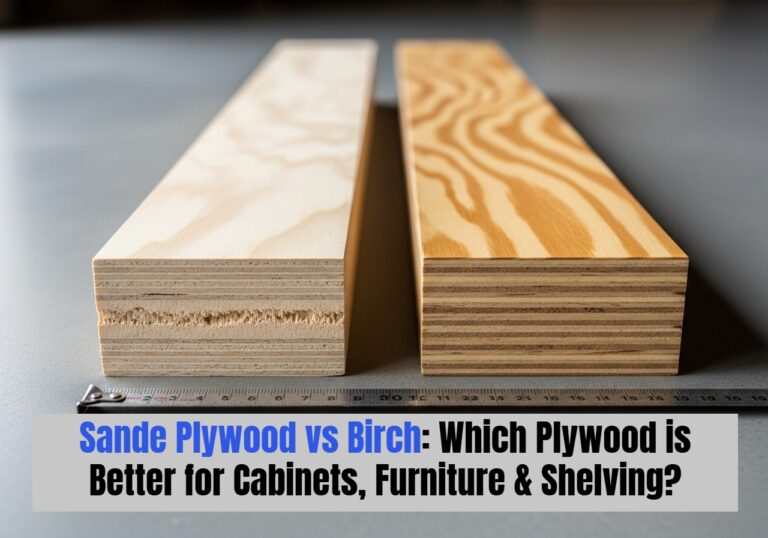

For Indoor Furniture and Cabinetry

Birch Plywood (Cabinet Grade)

Birch plywood features higher-quality veneers with minimal surface defects, making it ideal for visible applications like cabinetry and fine furniture. The smooth surface accepts stain and finish beautifully. Birch’s uniform grain and appearance create professional-looking results. However, birch costs substantially more than CDX and offers no advantage for structural or outdoor applications.

Medium-Density Fiberboard (MDF)

MDF provides a smooth, stable base for painting and veneering, making it popular for cabinet interiors and built-in furniture. MDF machines cleanly without splintering and accepts paint flawlessly. However, MDF lacks structural strength, swells when wet, and isn’t suitable for exterior or moisture-prone areas. It works excellently for interior cabinetry in dry environments.

Particle Board

Particle board is the most budget-friendly option for interior, dry-area furniture. It provides adequate rigidity for light-duty applications like shelving and cabinet bottoms. However, particle board lacks structural strength, deteriorates quickly when wet, and has poor screw-holding ability. Reserve particle board for non-structural interior applications where cost is paramount.

Specialty/Other Options

Fiber Cement Boards

Fiber cement boards (including magnesium oxide boards) offer fire resistance, waterproofing, and superior durability for specialized applications. These boards work excellently as sheathing in wet environments, as backer boards for tile, and in fire-rated assemblies. The premium cost limits use to applications requiring their specific properties. For standard structural or sheathing applications, CDX remains more economical.

CDX Plywood FAQs

What Does CDX Stand For in Plywood?

CDX stands for the veneer grades (C and D) and the adhesive type (X for exterior). The C-grade face veneer allows knots up to 1.5 inches and repairs, making it suitable for structural applications where appearance matters less. The D-grade back veneer permits even more defects, reducing cost while maintaining functionality. The X designation indicates exterior-grade phenolic adhesive providing moisture resistance. Together, CDX describes plywood engineered for outdoor and structural use with moisture-resistant bonding.

Are There Lighter Alternatives to CDX?

Yes, several lighter alternatives exist, particularly for roofing applications. Oriented Strand Board (OSB) weighs about 15% less than traditional CDX plywood, significantly reducing transport and labor costs on large roofing projects. OSB’s lighter weight makes handling easier and reduces labor difficulty. Advantech is a premium OSB variant offering durability and moisture resistance comparable to CDX while weighing slightly less.

Thermoply combines structural sheathing with integrated insulation, reducing the number of layers needed and further decreasing weight while improving thermal efficiency. When selecting among lighter alternatives, weigh the cost savings against the specific durability and moisture-resistance requirements of your project.

When Should You Choose OSB Over CDX?

Choose OSB when budget is the primary concern and the application allows compromises in moisture performance. OSB works well for temporary bracing, interior wall sheathing in protected environments, and projects where rapid installation and cost minimization matter most. OSB offers excellent shear strength for lateral bracing. However, if your project involves permanent outdoor exposure, high-moisture environments, or applications requiring rapid drying after rain, CDX’s superior moisture behavior justifies the higher cost.

Is CDX Plywood Pressure Treated?

Standard CDX plywood is not pressure treated. CDX’s moisture resistance comes from exterior-grade phenolic adhesive, not chemical preservatives. However, pressure-treated plywood is available with exterior-grade adhesive, providing both the chemical preservative protection and moisture-resistant glue. Pressure-treated CDX-style plywood costs more but offers superior protection for ground-contact applications and high-moisture environments. Confirm whether you need standard CDX or pressure-treated CDX when ordering, as they’re distinct products with different applications and costs.

Can CDX Plywood Get Wet?

CDX plywood can withstand moisture exposure and rain without the adhesive failing, unlike interior plywood that delaminations when wet. However, “can withstand moisture” doesn’t mean “waterproof.” The veneer itself absorbs water, which can cause swelling, warping, and potential rot if exposure is prolonged without protective finishes. CDX resists the specific failure mode of adhesive breakdown, but you should still protect it with sealants, paint, or other weather-resistant coatings for long-term durability. The exterior-grade adhesive prevents catastrophic failure, but finish protection prevents wood degradation.

How Long Does CDX Plywood Last?

With proper maintenance and finish protection, CDX plywood can last 10-20+ years in outdoor applications. Interior applications where moisture exposure is minimal can last 20-30+ years. However, unprotected CDX exposed to weather deteriorates much faster; potentially within 3-5 years. Lifespan depends primarily on finish maintenance, environmental exposure, and local climate. Regular recoating and minor repairs extend life significantly. Pressure-treated alternatives last longer in harsh conditions, while marine plywood provides maximum longevity in high-moisture environments.

Conclusion

CDX plywood remains an industry-standard building material for excellent reasons: its combination of moisture-resistant adhesive, cross-grain strength, affordability, and widespread availability makes it the logical choice for most structural and exterior applications. Understanding the manufacturing process, proper applications, sizing options, and maintenance requirements allows you to maximize its performance and value.

Whether you’re framing a roof, sheathing exterior walls, creating concrete formwork, or undertaking structural work, CDX plywood delivers reliable performance at economical cost. Proper selection of appropriate thickness, careful inspection before use, protective finishing, and regular maintenance ensure your plywood investment provides decades of structural integrity and protection.

For applications demanding premium performance or specialized requirements, alternatives like pressure-treated or marine plywood offer enhanced benefits. But for most construction projects, CDX plywood’s proven performance and cost-effectiveness make it the smart choice for builders and DIYers alike.

Bình luận