Plywood vs OSB: 8 Key Differences That Decide Your Subfloor Choice

When choosing materials for subfloors, structural sheathing, or industrial applications, plywood and OSB are two of the most commonly compared engineered wood products. Both are widely used across residential construction, commercial buildings, furniture manufacturing, and protective packaging. While they may appear similar at first glance, plywood and OSB differ significantly in structure, performance, moisture behavior, fastening ability, and long-term durability.

Understanding the key differences between plywood and OSB is essential for selecting the right material for your project. The wrong choice can lead to premature wear, moisture-related issues, noise problems, or unnecessary costs. This guide provides a detailed comparison of plywood vs OSB, helping builders, architects, manufacturers, and procurement teams make informed decisions based on real-world performance rather than assumptions.

What Is Plywood?

Plywood Definition

Plywood is an engineered wood product made from multiple thin layers of wood veneer, known as plies. These plies are bonded together using adhesive, with the grain direction of each layer rotated 90 degrees relative to the adjacent layer. This cross-laminated structure significantly enhances strength, dimensional stability, and resistance to warping or splitting.

The wood species used in plywood production varies by region and manufacturer. Common species include eucalyptus, pine, fir, birch, ash, beech, and spruce, while premium plywood may incorporate hardwoods such as oak, maple, teak, or mahogany. Because plywood is made from natural veneers, slight variations in thickness, grain pattern, and appearance may occur across panels.

At Kosemex, plywood is produced for a wide range of structural, furniture, and industrial applications, with consistent quality control and compliance with international standards such as CE and FSC.

Plywood Pros and Cons

Pros

-

Dries faster after moisture exposure and returns closer to its original dimensions

-

Swells less than OSB and shows better recovery once dried

-

Holds screws, nails, and fasteners more securely, reducing movement and floor squeaks

-

Offers higher stiffness and rigidity in many structural applications

-

Generally off-gasses fewer harmful emissions compared to OSB

-

Proven long-term performance in subfloors, roofing, and load-bearing systems

Cons

-

Typically more expensive than OSB

-

Limited availability in very large panel sizes

-

Veneer-based construction may contain voids or gaps, depending on grade

-

Lower-quality plywood may delaminate under extreme humidity or heat if adhesives are insufficient

What Is OSB?

OSB Definition

Oriented Strand Board, commonly known as OSB, is an engineered wood panel made from large, thin wood strands arranged in layers. These strands are bonded with resin and compressed under heat and pressure to form a dense, uniform panel. Unlike plywood, OSB does not use veneer sheets, and its structure is more homogeneous throughout the panel.

OSB evolved from waferboard, which was first manufactured in the early 1960s. By the early 1990s, OSB had largely replaced waferboard due to its improved structural performance and consistency.

OSB Pros and Cons

Pros

-

Lower cost compared to plywood, suitable for budget-driven projects

-

Available in larger panel sizes, improving material efficiency

-

Uniform density with fewer internal voids or soft spots

-

Consistent load distribution across the panel

-

Often considered more resource-efficient due to use of small, fast-growing trees and wood scraps

Cons

-

Heavier than plywood, increasing handling and installation effort

-

Weaker screw and nail holding capacity, especially along panel edges

-

Poor moisture recovery; edge swelling often remains after drying

-

Swelling can compromise surface flatness and long-term performance

-

Typically higher formaldehyde off-gassing compared to plywood

OSB vs Plywood: 8 Key Differences

How They Are Made

Plywood is manufactured by bonding multiple veneer layers together with alternating grain directions, creating a cross-laminated structure. This construction provides excellent tensile strength, resistance to warping, and better recovery from moisture-related movement. In contrast, OSB is produced by orienting wood strands in layers and compressing them into a dense, uniform panel.

The structural difference is critical. Plywood’s layered veneers offer better dimensional recovery after swelling, while OSB’s uniform structure enhances stiffness and shear strength.

Strength and Load-Bearing Performance

Both materials perform well structurally, but in different ways. OSB provides consistent strength across the entire panel due to the absence of voids. Plywood, however, generally offers higher stiffness and approximately 10 percent more rigidity in subfloor applications. This makes plywood better suited for heavy loads and flooring systems that require minimal deflection, such as tile or stone installations.

Weight

OSB panels are typically heavier than plywood panels of the same thickness. This additional weight can increase labor effort during installation and transportation, particularly on large projects.

Installation and Fastening

Plywood holds screws, nails, and fasteners more securely, especially near edges. This improves floor stability and reduces the risk of squeaks over time. OSB’s reduced fastening grip can require closer fastener spacing and more careful installation practices.

Moisture Resistance and Stability

Moisture behavior is one of the most significant differences. Plywood swells less when exposed to water and generally recovers better after drying. OSB tends to swell at the edges and retain that swelling, creating visible ridges that can telegraph through flooring or roofing materials.

Cost and Long-Term Value

OSB’s lower upfront cost makes it appealing for budget-driven projects. However, plywood often delivers better long-term value due to its durability, reduced maintenance issues, and better performance in variable environmental conditions.

Noise Control

Because plywood holds fasteners more securely and flexes less under load, it is less prone to movement-related noise such as floor squeaks. OSB floors may require additional measures to achieve similar noise performance.

Environmental Considerations

OSB is often viewed as more resource-efficient due to its use of smaller trees and wood waste. Plywood, while using larger veneer logs, may offer longer service life, which can offset environmental impact over time depending on application.

OSB vs Plywood Comparison Table

| Criteria | Plywood | OSB (Oriented Strand Board) |

|---|---|---|

| Manufacturing method | Made from cross-laminated wood veneers bonded with adhesive | Made from compressed wood strands oriented in layers |

| Structural strength | High stiffness and rigidity, good load-bearing performance | Strong and uniform shear strength across panels |

| Dimensional stability | Better resistance to warping and deformation | More prone to permanent edge swelling |

| Moisture behavior | Swells less and recovers better after drying | Absorbs moisture slowly but dries very slowly |

| Edge performance | Stronger edges, better fastener grip | Edges weaken more easily when wet |

| Fastener holding | Excellent screw and nail holding capacity | Weaker fastener holding, especially near edges |

| Noise resistance | Less movement, fewer floor squeaks over time | Higher risk of movement-related noise |

| Panel weight | Lighter than OSB at the same thickness | Heavier, increasing handling effort |

| Panel size availability | More limited in extra-large formats | Available in larger panel sizes |

| Surface appearance | Smoother, more suitable for visible applications | Rougher surface, mainly structural use |

| Environmental aspect | Longer service life, depending on application | Efficient use of fast-growing trees and wood waste |

| Off-gassing | Generally lower formaldehyde emissions | Typically higher formaldehyde emissions |

| Cost | Higher upfront cost | Lower upfront cost |

| Typical applications | Subfloors, roofing, furniture, cabinetry, packaging | Wall sheathing, roof decking, cost-driven construction |

OSB vs Plywood: Which Is Better?

The choice between OSB and plywood depends entirely on the project’s priorities. For subfloors, roofing, and applications exposed to moisture or heavy loads, plywood often provides superior performance and longevity. For large-scale projects where cost control, panel size, and uniformity are critical, OSB can be an effective solution.

In industrial packaging and protective applications, designers must also consider weight, exposure conditions, and whether the material will be visible to end users. Environmental goals may further influence the decision.

OSB vs Plywood FAQs

Plywood vs OSB: Which Subfloor Material Lasts Longer?

Plywood typically lasts longer in subfloor applications, particularly in environments where moisture exposure is possible.

Why Use Plywood Over OSB?

Plywood offers better moisture recovery, stronger fastening, and improved stiffness, making it ideal for high-performance flooring and structural systems.

Can OSB Be Stronger Than Plywood?

OSB provides excellent shear strength and uniform load distribution, but plywood generally offers better overall rigidity and dimensional stability.

OSB vs Plywood for Roofing and Flooring

Plywood performs better under moisture exposure and heavy loads, while OSB is often chosen for cost-driven roofing and wall systems in dry conditions.

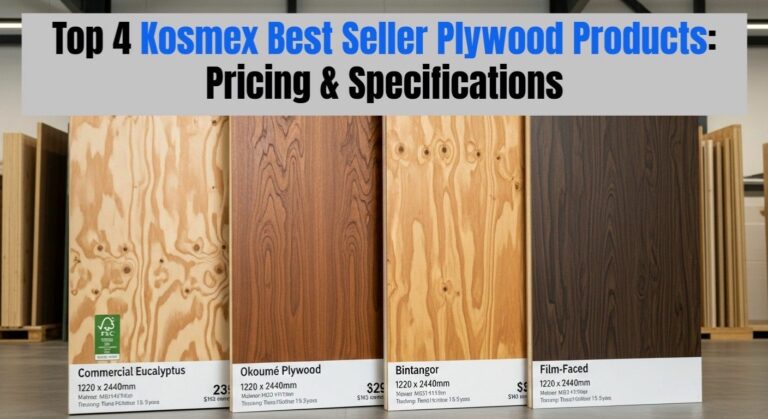

Kosemex – A Leading Plywood Supplier in Southeast Asia

Kosemex is a leading plywood manufacturer and exporter in Southeast Asia, supplying certified plywood products to global markets including Europe and North America. All products comply with international standards such as CE marking and FSC certification, ensuring quality, sustainability, and traceability.

With large-scale production capacity and stable raw material sourcing, Kosemex is capable of delivering consistent quality and high volumes for long-term projects. This makes Kosemex a trusted partner for construction companies, furniture manufacturers, distributors, and industrial buyers seeking reliable plywood solutions.

For product specifications, samples, or commercial inquiries, contact Kosemex for product specifications, samples, or commercial inquiries:

WhatsApp: +84 399 741 589

Email: anna@kosmexgroup.com

Bình luận