Standard Plywood Sizes: Complete Guide to Dimensions, Thickness, and Global Variations

Choosing the right plywood size is a fundamental decision that directly affects structural integrity, material efficiency, cost control, and installation quality. Whether plywood is used for construction, furniture manufacturing, cabinetry, or interior finishing, understanding standard dimensions and thickness options helps prevent material waste and performance issues.

This guide provides a complete overview of plywood sizes, explaining what is considered standard, how plywood dimensions vary by application, and how different countries approach sizing. By the end of this article, readers will have a clear framework for selecting plywood sizes that align with both technical requirements and practical project needs.

What are the Standard Plywood Sizes?

Standard plywood sizes refer to the most commonly manufactured and widely available sheet dimensions in the global market. These sizes are not arbitrary; they are designed to align with typical construction modules, framing systems, and material handling practices.

While exact standards may vary slightly by region, most plywood manufacturers produce panels within a limited set of globally recognized dimensions. These standard sizes reduce cutting time, minimize waste, and simplify design planning across residential, commercial, and industrial applications.

It is also important to distinguish between nominal size and actual size. Nominal size refers to the stated dimension, while actual size may be slightly smaller due to trimming, sanding, and manufacturing tolerances.

Why Understanding Plywood Sizes Matters

Plywood is produced in large panel formats to cover wide surfaces efficiently. However, not all projects require the same sheet dimensions or thickness. Using oversized panels for small-scale furniture can increase waste, while undersized or overly thin plywood in structural applications can compromise safety.

Understanding plywood sizes allows builders, designers, and buyers to balance strength, cost, and material efficiency. It also simplifies logistics, cutting plans, and installation workflows, particularly in large-scale or export-oriented projects.

What Sizes Does Plywood Come In?

Standard Plywood Widths and Lengths

The most widely used plywood sheet size worldwide is 4 × 8 feet, which corresponds to approximately 1220 × 2440 millimeters. This size is popular because it aligns well with standard wall framing and floor joist spacing, making it ideal for construction and structural applications.

Another common size, particularly in Asian and export markets, is 5 × 5 feet, or approximately 1250 × 2500 millimeters. This format is frequently used for concrete formwork, industrial applications, and projects that benefit from slightly larger surface coverage.

| Nominal Size (Feet) | Size (Millimeters) | Common Markets | Typical Applications |

|---|---|---|---|

| 4 × 8 ft | 1220 × 2440 mm | Global (US, EU, Asia) | Construction, subflooring, wall sheathing, roofing |

| 5 × 5 ft | 1250 × 2500 mm | Asia, Export markets | Concrete formwork, industrial use |

| 4 × 10 ft | 1220 × 3050 mm | North America (limited) | Large wall panels, fewer joints |

| 3 × 6 ft | 915 × 1830 mm | Furniture & interior projects | Cabinets, small furniture components |

| Custom sizes | Cut to order | Project-based | Furniture manufacturing, modular systems |

In addition to these, some manufacturers offer extended-length panels for specific industrial uses. However, availability depends on production capacity and transportation constraints.

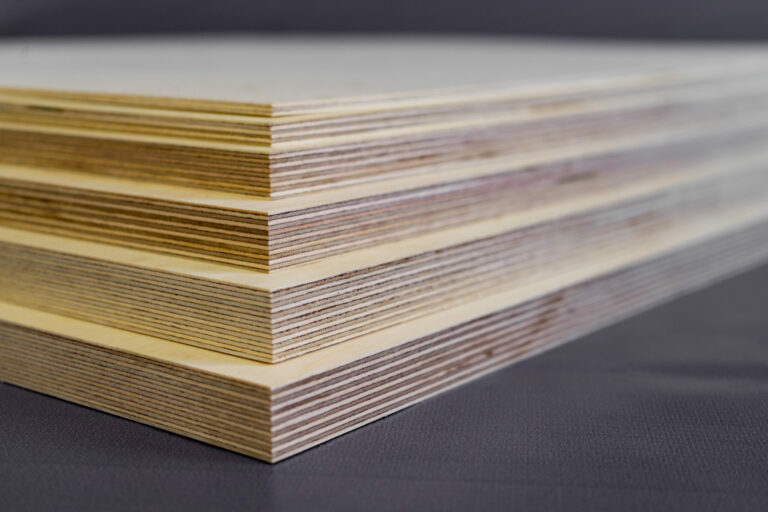

How Thick Is Plywood?

Plywood thickness plays a critical role in determining load-bearing capacity, stiffness, and overall durability. Thickness selection should always be based on application requirements rather than appearance alone.

Plywood is typically produced in a wide range of thicknesses, from very thin panels used for decorative purposes to thick structural panels designed to support significant loads.

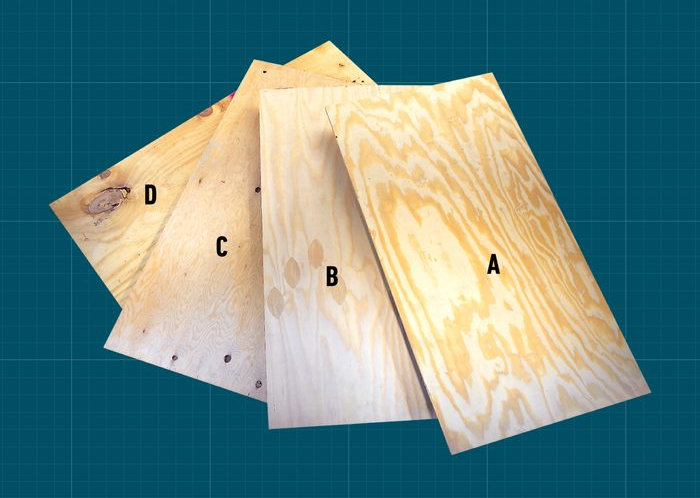

Common Plywood Thicknesses and Their Uses

Thin plywood, around 6 millimeters (approximately 1/4 inch), is commonly used for lightweight applications such as drawer bottoms, cabinet backs, decorative panels, and interior cladding. Its low weight makes it easy to handle, but it offers limited structural strength.

Medium-thickness plywood, around 12 millimeters (approximately 1/2 inch), is widely used for cabinet making, wall panels, and furniture components. This thickness provides a balance between strength and weight, making it suitable for both functional and semi-structural uses.

| Thickness (mm) | Thickness (Inch) | Structural Capacity | Typical Uses |

|---|---|---|---|

| 3-4 mm | ~1/8 inch | Very low | Decorative panels, backing boards |

| 6 mm | 1/4 inch | Low | Drawer bottoms, cabinet backs, wall cladding |

| 9 mm | 3/8 inch | Medium-low | Interior panels, lightweight furniture |

| 12 mm | 1/2 inch | Medium | Cabinets, partitions, wall panels |

| 15 mm | ~5/8 inch | Medium-high | Furniture frames, shelving |

| 18 mm | 3/4 inch | High | Flooring, heavy-duty furniture, subfloors |

| 21-25 mm | 7/8-1 inch | Very high | Structural platforms, industrial use |

Thicker plywood, typically around 18 millimeters (approximately 3/4 inch), is frequently used for flooring systems, shelving, heavy-duty furniture, and structural applications. Its increased stiffness and load-bearing capacity make it a reliable choice where durability is essential.

Some specialized applications may require plywood thicker than 18 millimeters, especially in industrial or heavy-load environments.

Specialized and Custom Plywood Sizes

Beyond standard dimensions, many plywood suppliers offer custom sizes tailored to specific project requirements. Custom cutting allows manufacturers to reduce on-site labor, minimize material waste, and improve installation efficiency.

Custom-sized plywood is particularly useful in furniture production, modular construction, and export projects where container optimization and precise fitting are important. However, custom sizes may involve longer lead times and higher production costs.

Plywood Size Tolerances

Manufacturing tolerances refer to the acceptable variation between nominal and actual plywood dimensions. Small deviations in length, width, or thickness are normal and allowed within industry standards.

Understanding size tolerances is especially important for projects requiring precise alignment, such as cabinetry, prefabricated components, or large-scale installations. Consistent tolerances contribute to smoother installation and better overall finish quality.

How Plywood Size Affects Different Applications

Plywood size directly influences how panels perform in real-world applications. Larger sheets reduce the number of joints, improving structural continuity and visual consistency. Smaller sheets, on the other hand, are easier to handle and may be more efficient for furniture or decorative projects.

Thickness selection also affects vibration resistance, load distribution, and fastening strength. Choosing the right size and thickness combination ensures that plywood performs as intended without unnecessary material use.

5 Tips to Choose the Right Plywood Size for Your Project

Consider the Project Scope and Layout

Before selecting plywood, it is essential to assess the overall project scope. Large surface areas benefit from standard large sheets that minimize seams, while smaller or more detailed projects may require reduced dimensions for ease of handling and cutting accuracy.

Match Plywood Size with Application Type

Different applications impose different demands on plywood size. Construction and structural projects prioritize large, thick panels, while furniture and cabinetry often require moderate sizes that allow precise fabrication and finishing.

Choose the Right Thickness for Load Requirements

Thickness should always be chosen based on expected loads and span lengths. Thinner panels may appear cost-effective initially but can lead to deflection or failure if used beyond their capacity.

Balance Material Efficiency and Cutting Waste

Selecting plywood sizes that closely match design dimensions helps reduce offcuts and waste. This not only lowers material costs but also improves sustainability by maximizing resource utilization.

Check Supplier Capabilities and Custom Options

Not all suppliers offer the same size range or custom cutting services. Working with a manufacturer capable of producing consistent standard and custom sizes ensures smoother project execution, especially for large or repeat orders.

Standard Plywood Sizes by Application

Plywood Sizes for Construction and Structural Use

In construction, plywood is commonly used for subfloors, wall sheathing, and roofing. The standard 4 × 8 feet sheet is widely favored because it aligns with framing layouts and provides efficient coverage. Thickness typically ranges from 12 to 18 millimeters, depending on load requirements and spacing.

Plywood Sizes for Furniture and Cabinet Making

Furniture and cabinetry often require more precise sizing to achieve clean lines and accurate joints. Medium-sized panels and moderate thicknesses are commonly selected to balance strength and workability. Custom-sized panels are frequently used in this sector to optimize production efficiency.

Plywood Sizes for Decorative and Interior Projects

Decorative applications such as wall panels, ceilings, and artistic installations often use thinner plywood in smaller formats. These sizes are easier to handle and install, especially when appearance rather than structural strength is the primary concern.

Plywood Sizes in Different Countries

Plywood Sizes in Sri Lanka

In Sri Lanka, plywood sizes commonly follow international standards, with 4 × 8 feet sheets widely available. Thickness selection varies by application, and pricing is influenced by import costs and wood species availability.

Plywood Sizes in the Philippines

The Philippine market commonly uses both 4 × 8 feet and metric-sized panels. Plywood is widely used in construction and interior projects, with size and thickness choices reflecting local building practices and climate considerations.

Plywood Sizes in Nigeria

Nigeria’s plywood market includes a mix of locally produced and imported panels. Standard sizes are commonly used, but availability may vary depending on supply chains and import regulations.

Plywood Sizes in Ghana

In Ghana, plywood sizes are influenced by construction demand and regional trade. Standard sheet formats dominate, with thickness choices aligned to residential and commercial building needs.

Plywood Sizes in Australia

Australia generally follows standard international plywood dimensions, with a strong emphasis on compliance with building codes. Thickness selection is carefully regulated for structural applications.

Plywood Sizes in Canada

Canada primarily uses North American standard plywood sizes, especially the 4 × 8 feet format. Thickness and grade requirements are closely tied to structural standards and climate conditions.

Relationship Between Plywood Size and Price

Plywood size has a direct impact on pricing. Larger and thicker panels require more raw material and energy to produce, increasing cost. Custom sizes may further affect pricing due to additional processing and reduced production efficiency.

Understanding how size and thickness influence price helps buyers evaluate cost in relation to performance and long-term value rather than focusing solely on initial expense.

Designed for applications where surface grip and safety are critical, anti-slip film faced plywood is commonly used for construction flooring, scaffolding platforms, and container floors. Kosemex anti-slip panels are available in thicknesses from 9mm to 21mm, with standard sheet sizes of 1220 × 2440mm and 1250 × 2500mm, ensuring consistent performance and easy integration into structural layouts.

Common Mistakes When Choosing Plywood Sizes

A common mistake is selecting plywood without considering how size affects installation and performance. Ignoring thickness requirements, overlooking tolerances, or choosing dimensions that lead to excessive waste can all compromise project outcomes.

Careful planning and alignment between design requirements and plywood sizing help avoid these issues.

Plywood Size FAQs

What is the standard size of plywood?

The most common standard size is 4 × 8 feet, or approximately 1220 × 2440 millimeters.

What is the size of plywood in centimeters?

Standard plywood sheets typically measure around 122 × 244 centimeters.

What size is an 8 × 4 sheet of plywood in millimeters?

An 8 × 4 sheet measures approximately 2440 × 1220 millimeters.

What size plywood is used for roofing?

Roofing commonly uses standard sheets with sufficient thickness to meet load and spacing requirements.

What size plywood is suitable for a ceiling or attic floor?

Size and thickness depend on structural design and load expectations.

In practice, standard plywood sizes and thicknesses are most commonly applied in specific product categories, particularly in construction and formwork applications. The following plywood types illustrate how standardized dimensions are used across different use cases.

Conclusion: Choosing the Right Plywood Size for Better Performance

Understanding plywood sizes is essential for achieving reliable performance, efficient material use, and cost-effective construction. By considering standard dimensions, thickness options, application requirements, and regional variations, buyers can select plywood sizes that support both structural integrity and practical execution.

Selecting the right plywood size is not simply a technical detail, it is a strategic decision that influences the success and longevity of any woodworking or construction project.

Bình luận