Types of Plywood 2026: A Complete Guide to Classification, Grades and Applications

Plywood is one of the most essential engineered wood materials in modern construction, furniture manufacturing, and interior design. Although it is widely used across residential, commercial, and industrial projects, many buyers still struggle to distinguish between the different types of plywood available on the market and to understand which option best fits their specific needs.

This article provides a comprehensive explanation of all major types of plywood, examining how they are classified, how they perform under different conditions, and how they should be selected for practical applications. Rather than listing products superficially, the guide focuses on structure, material logic, and real-world use cases, helping readers make informed decisions based on performance rather than assumptions.

What is Plywood?

Plywood Definition

Plywood is an engineered wood panel manufactured by bonding multiple thin layers of wood veneer together under heat and pressure. Each veneer layer is arranged so that its wood grain runs perpendicular to the adjacent layer, forming a cross-laminated structure.

This construction method significantly enhances the panel’s mechanical strength and reduces the natural weaknesses found in solid wood, such as: cracking, splitting, and warping. As a result, plywood offers consistent quality and reliable performance across a wide range of structural and non-structural applications.

Why Plywood is Widely Used in Construction and Furniture

Plywood is widely used in construction and furniture manufacturing because it delivers an excellent balance between strength, stability, and cost. Its high strength-to-weight ratio allows plywood panels to support substantial loads without excessive material thickness, making them efficient for flooring, roofing, and furniture frames.

The cross-laminated structure also provides dimensional stability, meaning plywood is far less likely to expand, shrink, or deform when exposed to changes in temperature and humidity. In addition, plywood is more cost-efficient than solid wood for large-scale applications, as it maximizes the use of raw timber while maintaining reliable structural performance and surface quality.

How many Types of Plywood are there?

There is no fixed number that defines how many types of plywood exist. This is because plywood is classified using multiple criteria, including core composition, wood species, surface grade, performance standard, and intended application. Instead of counting categories, it is more accurate to understand plywood through these classification systems, which are explained in the following sections.

Types of Plywood by Core Material

Core structure has a direct impact on strength, weight, screw-holding capacity, and overall panel stability. Among all types of plywood, core composition is one of the most important technical distinctions.

Veneer Core Plywood

Veneer core plywood is constructed entirely from stacked wood veneers. Because the core and faces are made from the same material form, load distribution is balanced throughout the panel. This type offers strong fastening performance and consistent structural behavior, making it one of the most widely used formats in furniture manufacturing and construction projects.

Lumber Core Plywood

Lumber core plywood uses solid wood strips arranged side by side in the core, with veneer layers bonded on both faces. This structure increases stiffness and reduces bending, especially in wide panels. As a result, it is commonly used in doors, tabletops, and large furniture components where flatness is critical.

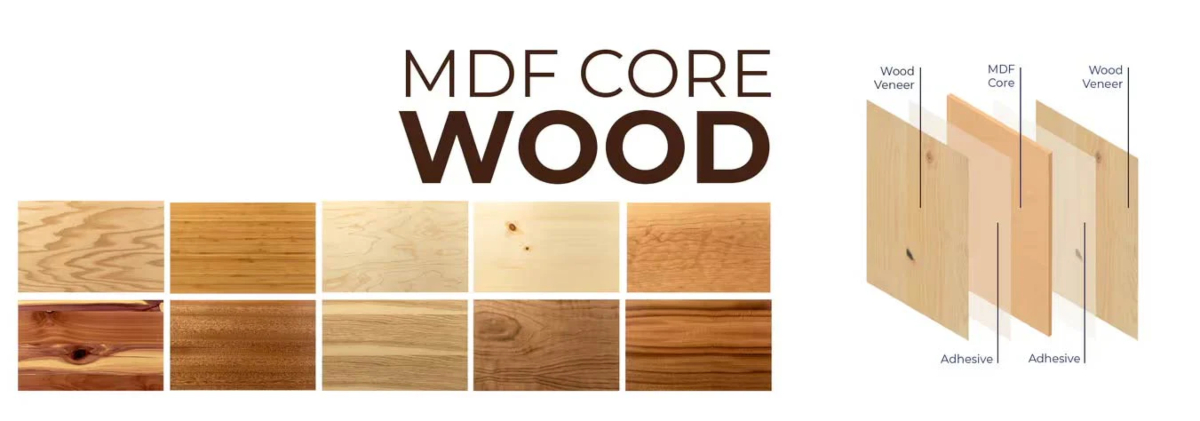

MDF Core Plywood

MDF core plywood combines a medium-density fiberboard core with decorative veneer faces. The MDF core provides a smooth and uniform surface, which is ideal for painted or laminated finishes. However, this type is less resistant to moisture than veneer-based alternatives and is therefore best suited for controlled interior environments.

Particle Core Plywood

Particle core plywood uses compressed wood particles in the core. While this construction lowers material cost, it also reduces screw-holding strength and load-bearing capacity. Among all types of plywood, particle core panels are generally limited to non-structural interior applications.

Types of Plywood by Wood Species

Wood species selection affects density, appearance, and mechanical performance across different types of plywood.

Hardwood Plywood

Hardwood plywood is manufactured from species such as birch, eucalyptus, acacia, rubberwood, or oak. These woods typically provide higher density and better bending strength, making hardwood plywood suitable for cabinetry, furniture, and decorative interiors where durability and aesthetics are important.

Softwood Plywood

Softwood plywood is produced from species such as pine, spruce, or fir. It is lighter in weight and more economical, which explains its widespread use in construction, sheathing, and structural panels where appearance is less critical.

Tropical Plywood

Tropical plywood is sourced from fast-growing hardwood species in tropical regions. It offers a balance between cost efficiency and mechanical performance and is widely used in export-oriented types of plywood, particularly in construction and industrial markets.

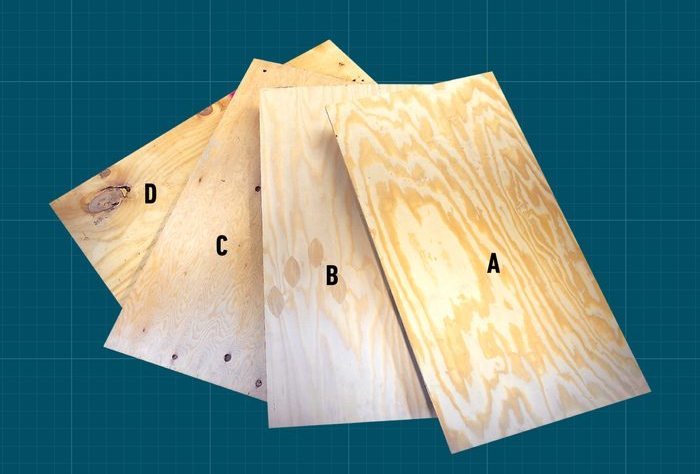

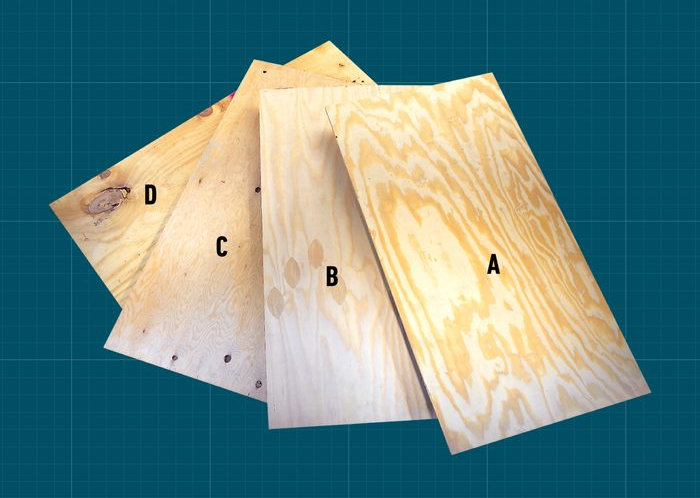

Types of Plywood by Grade

Plywood grades are primarily used to describe surface appearance rather than internal strength or load-bearing capacity. This grading system helps buyers understand how a plywood panel will look once installed, especially in applications where the surface remains visible. Regardless of core structure or wood species, these grades are applied consistently across most types of plywood.

Grade A Plywood

Grade A plywood features a smooth, fully sanded surface with minimal natural defects. Knots are either absent or very small and properly repaired, resulting in a clean and uniform appearance. This grade is commonly used in high-visibility applications such as furniture, cabinetry, wall panels, and decorative interiors, where surface quality and finish consistency are critical.

Grade B Plywood

Grade B plywood allows minor surface imperfections that have been neatly repaired using patches or filler. While the surface is not as flawless as Grade A, it remains visually acceptable for semi-visible applications. This grade is often selected for furniture components, shelving, or interior structures where the plywood surface may be partially exposed but is not the primary visual focus.

Grade C Plywood

Grade C plywood contains visible knots, patches, and natural wood characteristics that are not fully concealed. Although the surface appearance is less refined, the panel can still provide reliable structural performance when manufactured with proper core quality and adhesive systems. Grade C plywood is commonly used in construction, substructures, and areas that will be covered by other finishing materials.

Grade D Plywood

Grade D plywood represents the lowest surface appearance grade. It includes open knots, larger imperfections, and minimal surface repair. This grade is typically used in applications where appearance is not a concern, such as temporary structures, concealed framing, or industrial uses. Despite its rough appearance, Grade D panels may still be suitable for certain functional purposes when used appropriately.

These grading standards help differentiate visual quality across various types of plywood while allowing buyers to balance appearance requirements with cost and application needs.

Types of Plywood by Application

Many users prefer to understand types of plywood based on how and where the material will be used rather than how it is manufactured.’

Interior Plywood

Interior plywood is designed for dry environments and controlled humidity. It is commonly used in furniture, cabinetry, shelving, and wall paneling where moisture exposure is minimal.

Exterior Plywood

Exterior plywood is bonded with waterproof adhesives, allowing it to withstand exposure to moisture and weather conditions. It is suitable for outdoor structures, exterior walls, and areas subject to fluctuating humidity.

Structural Plywood

Structural plywood is engineered and tested to meet load-bearing requirements. It is commonly used in flooring systems, roofing decks, and structural framing where safety and performance standards must be met.

Construction Plywood

Construction plywood is a broad category that includes multiple types of plywood used in general building projects. Performance requirements vary depending on specific use cases and standards.

Specialty Types of Plywood

In addition to standard panels, the industry offers specialized types of plywood designed for demanding or niche applications.

Marine Plywood

Marine plywood is manufactured using high-quality veneers and phenolic glue, ensuring strong resistance to moisture and preventing core gaps. It is commonly used in boat building and high-humidity environments.

Film Faced Plywood

Film faced plywood is coated with phenolic film on both surfaces. This finish provides a smooth surface and high durability, making it ideal for concrete formwork systems where panels are reused multiple times.

Aircraft Plywood

Aircraft plywood is produced to strict specifications, offering exceptional strength-to-weight performance. It is used in aviation and other applications where lightweight strength is critical.

Flexible Plywood

Flexible plywood is designed to bend without cracking, making it suitable for curved surfaces and architectural design features.

Overlaid Plywood

Overlaid plywood incorporates resin-impregnated paper or decorative overlays, enhancing surface durability and appearance.

Types of Plywood for Specific Uses

Choosing the right types of plywood depends heavily on application requirements. Subflooring typically requires structural plywood with sufficient thickness and waterproof bonding. Roofing applications rely on exterior-grade panels that can withstand weather exposure. Cabinetry benefits from hardwood or MDF core plywood with stable surfaces. Flooring systems require high-density panels, while exterior walls demand moisture-resistant plywood with sealed edges.

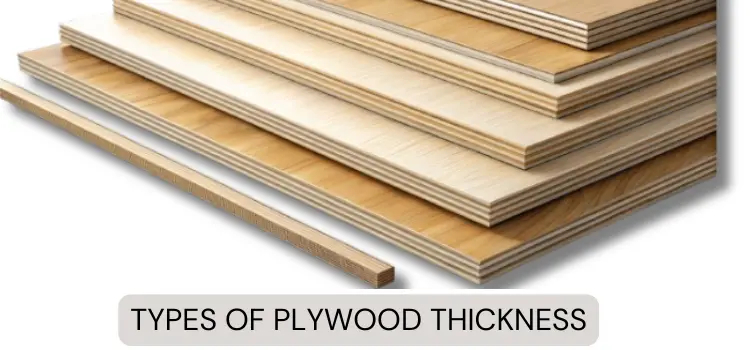

Plywood Sizes and Thicknesses

Most types of plywood are produced in standard sheet sizes such as 1220 × 2440 millimeters or 1250 × 2500 millimeters. Thickness options usually range from 3 millimeters to 25 millimeters. Selecting the appropriate thickness depends on span length, load conditions, and the specific application.

Types of Plywood and Pricing Considerations

Pricing varies significantly among types of plywood due to differences in raw materials, core quality, adhesive systems, and certification standards. Higher-priced panels typically reflect better bonding integrity, higher density, and longer service life. Understanding these factors helps buyers evaluate cost based on value rather than price alone.

5 common mistakes When Selecting Plywood

Mistakes often occur when buyers confuse commercial plywood with marine-grade panels, overlook adhesive specifications, or focus solely on cost. A clear understanding of the technical differences between types of plywood helps prevent premature failure and unnecessary replacement. In practice, there are five recurring mistakes that frequently lead to poor performance, increased maintenance costs, or even structural risks.

Confusing Commercial Plywood with Marine-Grade Plywood

One of the most common mistakes is assuming that all plywood labeled as “water-resistant” can be used interchangeably. Many buyers believe that commercial plywood and marine plywood offer similar moisture resistance, when in fact they are designed for very different environments. Commercial plywood is typically bonded with moisture-resistant or melamine glue, which performs adequately only in dry or semi-humid interior conditions. Marine plywood, by contrast, is manufactured using phenolic glue and higher-grade veneers, enabling it to withstand prolonged exposure to water without delamination. Confusing these two categories often results in swelling, edge separation, and early material failure in humid or outdoor applications.

Overlooking Adhesive Specifications

Another frequent mistake is ignoring adhesive specifications and focusing only on surface appearance or panel thickness. Adhesive performance is a critical factor in determining how plywood behaves under moisture, heat, and long-term stress. Even panels made from high-quality veneers will fail prematurely if bonded with an unsuitable glue. This issue becomes particularly serious in applications such as roofing, subflooring, and exterior walls, where temperature and humidity fluctuate regularly. Understanding adhesive classifications is essential when comparing different types of plywood and selecting panels that can maintain bonding integrity over time.

Choosing Plywood Based Solely on Price

Selecting plywood based only on price is a mistake that often leads to higher long-term costs. While budget constraints are a valid concern, the lowest-priced plywood usually involves compromises in core quality, veneer grading, or adhesive formulation. Inexpensive panels may contain core gaps, mixed-grade veneers, or diluted glue, all of which weaken structural performance. These hidden defects may not be visible at the time of purchase but can result in delamination, warping, or reduced load-bearing capacity. Evaluating overall value rather than initial cost alone is a more reliable approach when choosing between different types of plywood.

Ignoring Core Structure and Density Requirements

A fourth common error is neglecting core structure and density when selecting plywood. Buyers sometimes prioritize surface grade without considering whether the core material is appropriate for load-bearing or fastening requirements. For example, particle core plywood may appear suitable for certain interior uses but performs poorly under structural loads or repeated screw fastening. Core composition directly influences strength, stiffness, and durability, making it a decisive factor in applications such as flooring systems, cabinetry frames, and construction panels.

Failing to Match Plywood to the Application Environment

The final mistake is failing to align plywood specifications with the actual conditions in which the material will be used. Plywood installed in flooring, roofing, cabinetry, or exterior walls is exposed to very different mechanical stresses and environmental factors. Using interior-grade plywood in high-humidity areas or selecting appearance-grade panels for structural roles often results in underperformance and reduced service life. Understanding how different types of plywood are engineered for specific environments ensures that the selected material can perform reliably and safely over time.

Frequently Asked Questions About Types of Plywood

Are there different types of plywood?

Yes, plywood is classified by core structure, wood species, grade, and application.

What are the main types of plywood?

Interior, exterior, and structural plywood are the most common categories.

What are the four grades of plywood?

Grades A, B, C, and D describe surface quality.

Which plywood is best for outdoor use?

Exterior or marine plywood bonded with phenolic glue is recommended.

Conclusion

Understanding the full range of types of plywood is essential for selecting the right material for construction, furniture, or industrial use. There is no single plywood solution that fits every project. Instead, performance depends on matching core structure, wood species, adhesive system, grade, and application conditions. By approaching selection systematically, buyers can ensure long-term durability, safety, and cost efficiency from their chosen plywood.

Bình luận