Vietnam Plywood Export Price Trend: Complete 2025 Guide for Global Buyers

Are you losing money on unpredictable plywood price trend? Many importers struggle with sudden cost spikes, inconsistent quality, and suppliers who cannot explain price fluctuations.

This guide reveals how to navigate Vietnam plywood pricing, protect your margins, and partner with manufacturers who deliver stable costs even when global markets become volatile.

Understanding Vietnam Plywood Market Pricing for International Importers

Vietnam has established itself as one of the most reliable plywood supply centers for buyers in the European Union, United States, Middle East and Asian markets. International importers choose Vietnamese plywood manufacturers because of consistent production quality, flexible shipping arrangements, and highly competitive pricing when compared to alternatives from China, Indonesia or Russia.

The plywood export price is influenced by multiple factors including veneer availability, resin costs, government export regulations, and demand patterns from furniture manufacturing, construction projects and concrete formwork applications. Monthly price monitoring enables importers to optimize procurement timing, reduce cost volatility risks and protect profit margins throughout their supply chain.

Vietnamese plywood manufacturers offer an excellent balance of affordability, performance standards and international certifications. For buyers seeking predictable quality and sustainable business relationships, Vietnam represents a premium value proposition rather than simply a budget option.

This comprehensive analysis provides monthly price updates, current export conditions, and forward-looking market forecasts for the upcoming quarter.

Current Vietnam Plywood Export Prices: Monthly Market Data

Average FOB prices from Hai Phong Port and Cat Lai Port vary based on core wood species, adhesive bonding type, panel thickness and certification requirements including CE marking, FSC certification and laboratory test documentation.

Vietnam Commercial Plywood Price Table (FOB)

| Plywood Type | Price Range (USD/m³) | Price Difference vs MR Glue |

|---|---|---|

| Commercial Plywood MR Glue 1220 x 2440mm | $250 to $300 | Baseline pricing |

| Commercial Plywood Melamine Glue 1220 x 2440mm | $260 to $315 | +$10 to $15/m³ |

| Commercial Plywood Phenolic Glue 1220 x 2440mm | $350-400$ | +$35 to $50/m³ |

Note: Exact pricing depends on panel thickness, core quality, surface grade and order volume.

Vietnam Film Faced Plywood Price Table (FOB)

| Film Faced Plywood Specification | Price Range (USD/m³) | Key Features |

|---|---|---|

| Low Density Face + Hand Jointed Core + Melamine Glue | $280 to $300 | Entry level formwork grade |

| High Density Face + Composer Jointed Core + Melamine Glue | $350 to $380 | Superior core strength, no gaps |

| High Density Face + Composer Jointed Core + Phenolic Glue | $400 to $450 | Premium durability, maximum reuse cycles |

Note: Film faced plywood prices vary by thickness, film density (90-180 g/m²), core species and pressing requirements. High density film provides better surface finish and burn resistance.

Industry price patterns across thickness categories:

- 2.7mm to 9mm panels: Lower market demand with moderate price fluctuation

- 12mm to 18mm panels: Highest export volumes with stable pricing structure

- 21mm to 30mm panels: Specialty product orders with prices affected by core material supply and hot press production time

Export pricing closely tracks international resin markets. Phenolic resin costs remain higher than melamine resin alternatives, however panels manufactured with phenolic adhesive deliver substantially better durability, bending strength performance and long term moisture resistance.

European buyers increasingly prefer phenolic bonded plywood over melamine alternatives, driving stronger demand for high performance panels which can create modest price increases during peak shipping seasons.

Key Factors Affecting Vietnam Plywood Export Prices

Veneer Supply Market Conditions

Veneer pricing in Northern Vietnam fluctuates according to seasonal rainfall patterns, timber harvesting conditions and domestic manufacturing demand. Inconsistent veneer moisture content reduces factory production capacity and increases cost per cubic meter. Stable veneer supply chains enable predictable export pricing.

Resin Cost Fluctuations (Phenolic and Melamine Adhesives)

Phenolic resin prices show significant global volatility. Costs increase whenever crude oil markets rise or when major Chinese production facilities reduce output capacity. Melamine resin demonstrates greater price stability but still responds to international urea market conditions.

Premium Specification Orders

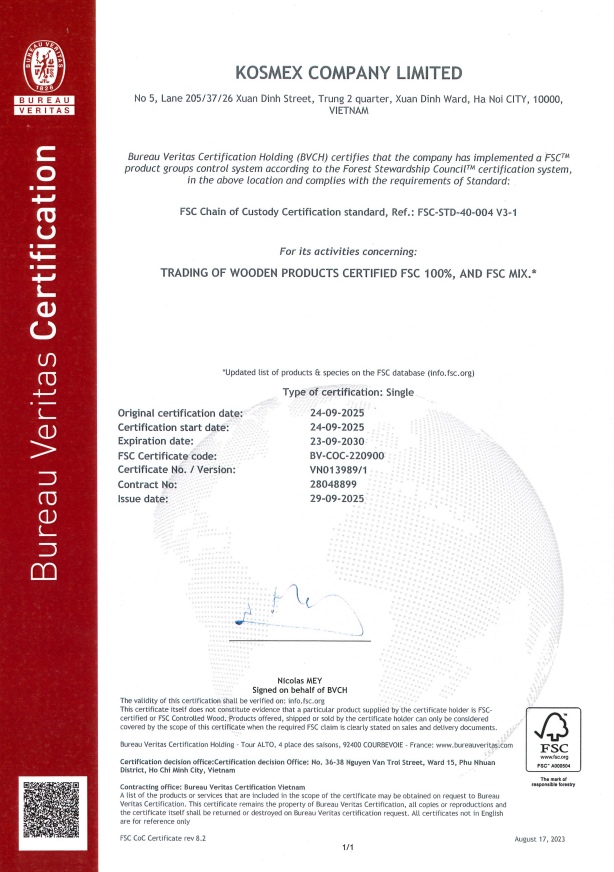

Panels requiring CE certification, FSC documentation, EN 310 testing or EN 314-2 water resistance testing command premium prices due to stricter quality control protocols. Orders specifying composer jointed cores, high density film face veneers or premium phenolic adhesive systems also impact total production costs.

Seasonal Market Demand Cycles

Furniture industry demand peaks before Christmas holidays and summer seasons. Formwork plywood demand increases during dry weather construction periods. These predictable cycles create moderate upward pressure on export prices.

Why Vietnamese Plywood Pricing Remains More Stable Than Other Asian Suppliers

Vietnam manufacturers consistently offer more predictable pricing because:

- Mills establish long term veneer supplier partnerships instead of spot market purchasing

- Production operations experience fewer disruptions from sudden government policy changes

- Exporters maintain strong relationships with European buyers generating predictable order volumes

- Mills operate with advanced automation reducing labor cost variability

Even during raw material cost increases, Vietnamese plywood avoids the sudden aggressive price jumps characteristic of certain competing markets.

Kosmex Manufacturing Advantages in Current Market Conditions

Most market analysis reports focus exclusively on price movements, but buyers also need suppliers who maintain consistent quality during cost fluctuations. Kosmex delivers distinct production advantages that sustain high performance even when material costs vary.

Advanced Core Production Technology

Kosmex utilizes composer machinery to joint core veneers. This eliminates core gaps and veneer overlaps, producing stronger adhesive bonding and fewer panel defects. Competitors using manual jointed cores experience inconsistent bonding quality and unpredictable load bearing performance.

Superior Surface Quality Standards

High density film face veneer ranging from 145 to 180 grams per square meter ensures clean, non burning surfaces and minimizes surface defects. Competing suppliers typically apply lower density film faces around 90 to 100 grams per square meter.

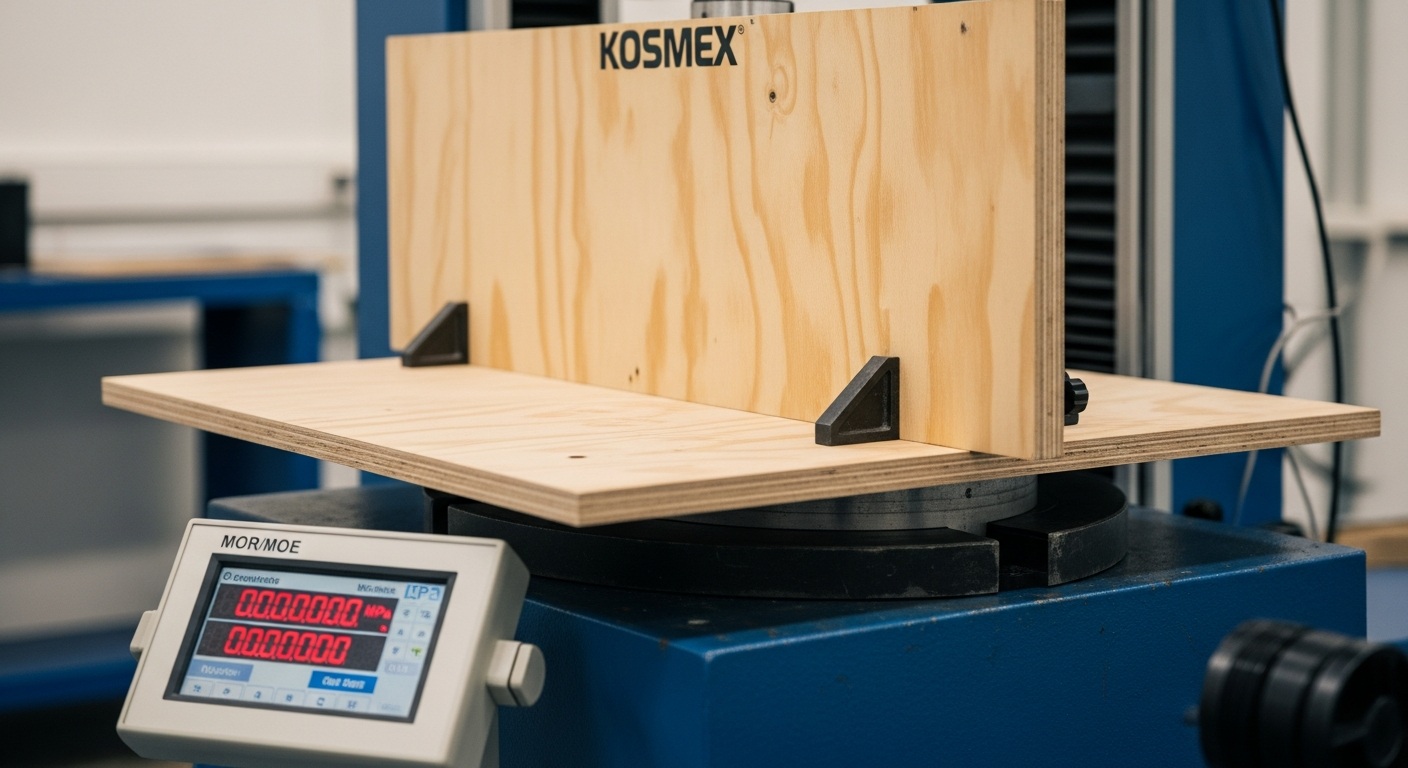

Structural Strength Performance

Kosmex maintains high bending strength panels manufactured to meet EN 310 performance standards. This makes panels suitable for sofa frames, bed base construction, cabinetry applications and concrete formwork systems.

Premium Adhesive Systems

Kosmex uses phenolic adhesive for high impact plywood applications, providing superior durability and moisture resistance. Many suppliers continue using melamine adhesive for cost reduction, resulting in compromised long term performance.

These production differences make Kosmex less vulnerable to raw material volatility and enable stable output quality and pricing even in fluctuating markets.

Vietnam Plywood Price trend forecast: Next quarter outlook

Based on current market analysis:

- Veneer prices are increasing due to heavy rainfall and flooding in raw material regions, which has disrupted timber harvesting and transportation. This upward pressure is expected to continue for the next 1 to 2 months until weather conditions stabilize

- Phenolic resin may increase moderately depending on global oil market trends

- European Union export demand recovering, particularly for phenolic bonded plywood

- Middle East construction orders increasing, raising demand for film faced plywood panels

Under these conditions, buyers should anticipate mild price adjustments without severe fluctuations. Bulk purchase orders and long term supply contracts will receive more stable pricing structures. Premium panels featuring high density film faces or machine jointed cores may experience slight increases due to higher resin costs.

Strategic Procurement Recommendations for International Importers

- Secure early pricing commitments for phenolic film faced plywood when project specifications require consistent quality

- Obtain CE certification and FSC documentation before finalizing long term supply contracts

- Request current EN 310 and EN 314-2 laboratory test reports matching your specific thickness requirements

- Evaluate physical panel samples by inspecting core gaps, bending stiffness and surface density

- Place trial container orders before peak shipping seasons

Buyers in the European Union, United States and Middle East markets who require dependable supply prefer manufacturers with controlled production processes over mills pursuing short term profit maximization.

Why Choose Kosmex for Export Quality Plywood Supply

Kosmex combines high performance manufacturing capabilities with international certification standards and transparent documentation. Key advantages include:

- Composer jointed cores eliminating gaps and overlaps

- High density surface veneer for enhanced durability

- Phenolic adhesive bonding for extended product lifespan

- Strong EN 310 bending test results

- CE marking and FSC certification available

- Independent laboratory reports from JAS and EN testing authorities

- Reliable monthly pricing and production capacity for repeat orders

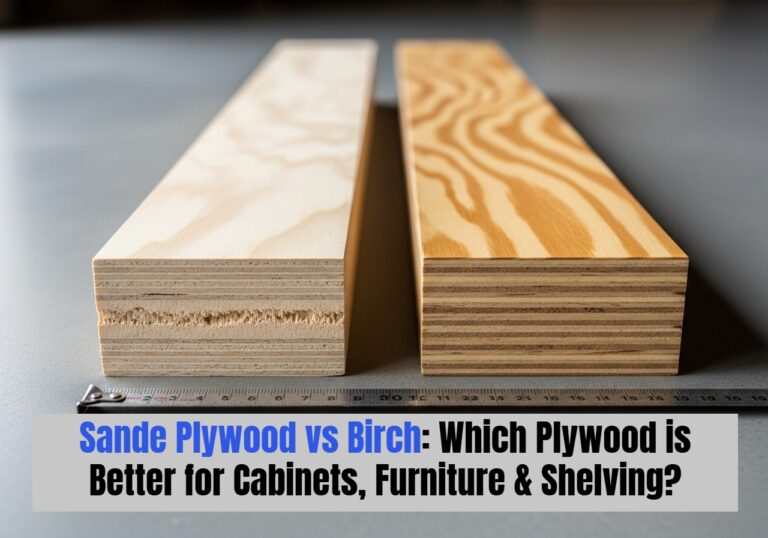

Kosmex positions itself as a premium commercial plywood supplier offering performance comparable to birch plywood at significantly lower cost, typically saving buyers 100 to 150 dollars per cubic meter.

Monthly Market Updates and Price Monitoring

This analysis updates monthly to reflect:

- Veneer input cost changes

- Resin market price fluctuations

- Export order volume trends

- Shipping and logistics developments

- New government policies affecting plywood trade

Buyers can subscribe to receive monthly price updates delivered directly.

Vietnam Plywood Export Market Summary

Vietnam plywood export prices remain among the most stable and competitive across Asian markets. With consistent raw material supply and robust export infrastructure, Vietnam continues as a preferred sourcing location for global buyers.

Kosmex enhances this market advantage through production methods delivering high structural strength, gap free cores and phenolic bonded durability meeting European Union and United States market standards.

Importers seeking reliable performance, transparent quality documentation and consistent monthly pricing will find Kosmex a dependable long term supply partner for commercial plywood applications.

KOSMEX CO., LTD. (Kosmex Group)

- Office address: House No. 5, Lane 205/37/26, Xuan Dinh Street, Trung 2 Residential Area, Xuan Dinh Ward, Hanoi City

- Factory address: Yen Son district, Tuyen Quang province

- Hotline: +84 399 741 589

- Email: anna@kosmexgroup.com | anna.kosmex@gmail.com

- Website: kosmexgroup.com

To speed up quoting, send three inputs in your first message: target thickness, fastening method (staple/screw + edge distances), and destination market (EU/non-EU). That’s the fastest path to qualifying high bending strength plywood from Kosmex against your birch baseline—using real production data, the way procurement teams prefer.

Bình luận