Common Defects in Plywood aren’t just “cosmetic.” They create rejects, rework, delays, and warranty risk—especially for buyers in furniture, packaging, and construction.

If you’ve ever discovered hollow “soft spots” only after cutting, coating, or mid-project, you already know the real cost: defects show up late, when fixing them is most expensive. This guide breaks down the most common plywood defect types, why they happen, how to spot them quickly, and how to avoid them with a repeatable QC checklist—plus how to shortlist low-defect factories such as Kosmex Group (Vietnam).

Common Defects in Plywood: Quick QC checklist (3 minutes per shipment)

Start with the job (so you check the right defects)

- Furniture / interior: face grade, sanding quality, moisture stability, warp control, clean glue lines

- Formwork / construction: bonding durability, thickness consistency, edge sealing, low core voids, predictable reuse cycles

- Packaging: core integrity + bonding consistency (visual grade can be lower if structure is stable)

Core defects: voids, overlaps & crushed core

The most expensive defects are often hidden inside the panel. Common core problems include:

- Core voids: open gaps between veneers

- Overlaps: veneer pieces stacked instead of sitting flat

- Crushed/broken core: damaged areas from handling, poor drying, or press settings

These defects reduce bending strength, create local “soft spots,” and can lead to failure in furniture frames, flooring, or formwork under load.

How to avoid these core defects (buyer actions):

- Ask your supplier for cross-cut photos/videos taken from random panels during production—not only packing photos.

- Confirm whether they rely on manual patching or a more consistent core-joining approach (and whether they can show process checkpoints).

- Request test evidence that matches your end use:

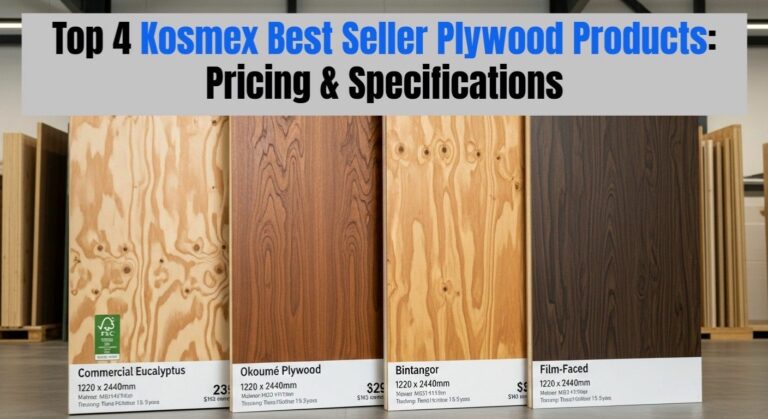

Where Kosmex fits: When you shortlist factories, prioritize suppliers that can show repeatable process control (not just one good batch). Use Kosmex’s published pages as a quick benchmark for transparency and a plywood QC system Vietnam buyers can actually audit, plus their EU program example: Eucalyptus plywood for the EU market.

Delamination & weak glue lines

Delamination happens when veneers separate along the glue line. In real use, you’ll see bubbling, edge lifting, or layers peeling after cutting or moisture exposure. It’s one of the most serious defects because it compromises strength and durability.

Typical root causes:

- Wrong adhesive system for the intended use

- Glue spread too low / uneven application

- Incorrect pressing parameters (temperature, pressure, time)

- Veneers too wet or contaminated before gluing

If you want an authoritative explanation of what makes strong, durable bonds (and why the process matters), see the USDA Forest Products Laboratory reference: USDA Forest Products Laboratory – Wood adhesives: bond formation & performance (FPL-GTR-282, 2021).

How to avoid delamination (buyer actions):

- Ask for bond evidence aligned with your use case (e.g., EN 314-2 class and supporting test documentation, or internal EN314 plywood bonding test reports from your supplier).

- Confirm the glue system used (UF / MUF / phenolic) and whether it matches your exposure conditions.

- Run a simple soak screening on sample offcuts to detect obvious early delamination before committing containers (screening only; lab tests decide acceptance).

Internal deep dive for furniture buyers: High bending strength plywood for furniture – complete guide.

Face veneer defects: knots, patches, splits & color issues

Even when the core is sound, face veneer issues can ruin a project—especially furniture, doors, cabinetry, or fair-faced concrete finishes:

- Large knots or knot holes

- Heavy patching/putty that sinks after painting

- Open splits that catch dust and moisture

- Color inconsistency between sheets (batch mismatch)

How to reduce face veneer defects:

- Specify face grades clearly in the PO/contract (e.g., B/BB, BB/BB)—not vague terms like “good quality.”

- Ask for high-resolution photos of random sheets from current production, not old catalog images.

- If volume matters, do a trial order and attach acceptance examples (OK vs reject photos).

Internal context: History of formation – 15 years of plywood manufacturing.

Thickness variation, warping & moisture problems

Common symptoms include uneven thickness across the panel, sheets that warp after storage, and edge swelling linked to wet veneers or poor storage.

How buyers can control these defects:

- Measure thickness at multiple points per sheet (corners + center) and record results per batch.

- Check moisture content with a meter—especially for furniture and indoor applications.

- Ask about drying control, sanding calibration, and in-process QC (moisture checks before gluing; thickness checks after sanding).

Factory transparency reference: Factory & Lab Test page.

Acceptance criteria template (copy into your PO)

EU documentation defects: missing DoP, unclear scope & traceability

In EU-facing supply chains, “paper defects” can be as costly as physical defects.

In EU-facing supply chains, “paper defects” can be as costly as physical defects.

For EU buyers (especially construction-related supply), documentation risk often looks like:

- CE logo shared without a valid Declaration of Performance (DoP)

- Unclear intended use + unclear standard scope for the product being purchased

- Certificates that cannot be verified or don’t match the real spec (thickness range, glue/bond class, end use)

How to avoid documentation defects:

- Ask for a complete documentation pack (DoP + relevant test reports)—not just a logo in an email.

- Use official references to align expectations: EU Commission: DoP & CE marking and EUR-Lex: CPR (EU) No 305/2011.

- Note (2025): CPR 305/2011 remains valid, but the new CPR Regulation (EU) 2024/3110 will apply progressively from 8 Jan 2026—buyers should start requesting traceable, digital-ready DoPs.

Internal guide for buyers who want to review a Vietnam plywood factory EU compliance example and get a clear CE certificate for plywood explanation.

How to shortlist a low-defect supplier (buyer view)

Shortlist suppliers who can show repeatable control + evidence (not just claims).

Shortlist suppliers who can show repeatable control + evidence (not just claims).

- Controlled core building (void/overlap prevention you can verify via cross-cuts)

- Repeatable bonding performance (glue disclosure + EN/JAS evidence)

- Stable thickness/moisture control (drying + sanding calibration + recorded QC)

- Export-ready documentation (DoP/test pack/traceability aligned to your market)

Kosmex positions its factory and content hub around these pillars—machinery transparency, lab testing orientation, and export-focused documentation. Useful internal starting points: Factory & Lab Test and EU market program example.

Contact Kosmex Group (Vietnam)

If you want to benchmark your current supplier against a low-defect, documentation-first factory in Vietnam, reach out to Kosmex:

- Company name: KOSMEX CO., LTD (Kosmex Group)

- Office address: House No. 5, Lane 205/37/26, Xuan Dinh Street, Trung 2 Residential Area, Xuan Dinh Ward, Hanoi City, Vietnam

- Factory address: Yen Son district, Tuyen Quang province, Vietnam

- Hotline: +84 399 741 589

- Email: anna@kosmexgroup.com & anna.kosmex@gmail.com

- Website: kosmexgroup.com

- Contact form: kosmexgroup.com/en/contact/

Bottom line: Common Defects in Plywood are predictable. If you define acceptance criteria early and choose suppliers who can show repeatable process control and evidence, you’ll cut rejects and rework drastically.

FAQ: Common questions about plywood defects

1) What are the most Common Defects in Plywood that buyers should watch for?

Prioritize core voids/overlaps, delamination, thickness variation/warp, edge swelling, and face defects that add labor (patches/splits/knots). These drive the biggest cost in rejects and rework.

2) Are all plywood defects visible from the surface?

No. The most expensive ones—core gaps and weak glue lines—can be hidden. That’s why cross-cut checks, soak screening, and transparent lab evidence matter.

3) Is “zero-defect plywood” realistic?

Not in mass production. A realistic requirement is low, controlled defect rates, clear grading rules, and a supplier that replaces out-of-spec material consistently.

4) How many defects are acceptable in furniture plywood?

It depends on grade and end use. High-end furniture needs strict limits on patches/knots and color variation, while packaging can accept more visual defects if bonding and core strength are consistent. Define limits in the PO/contract.

5) Why do EU buyers care so much about CE/DoP and test documentation?

Because documentation affects legal and financial risk. A clear DoP/test pack and traceability protect you during disputes, inspections, or project claims—especially in EU-facing supply chains.

Bình luận