How to Choose Plywood for Formwork (Contractor Guide)

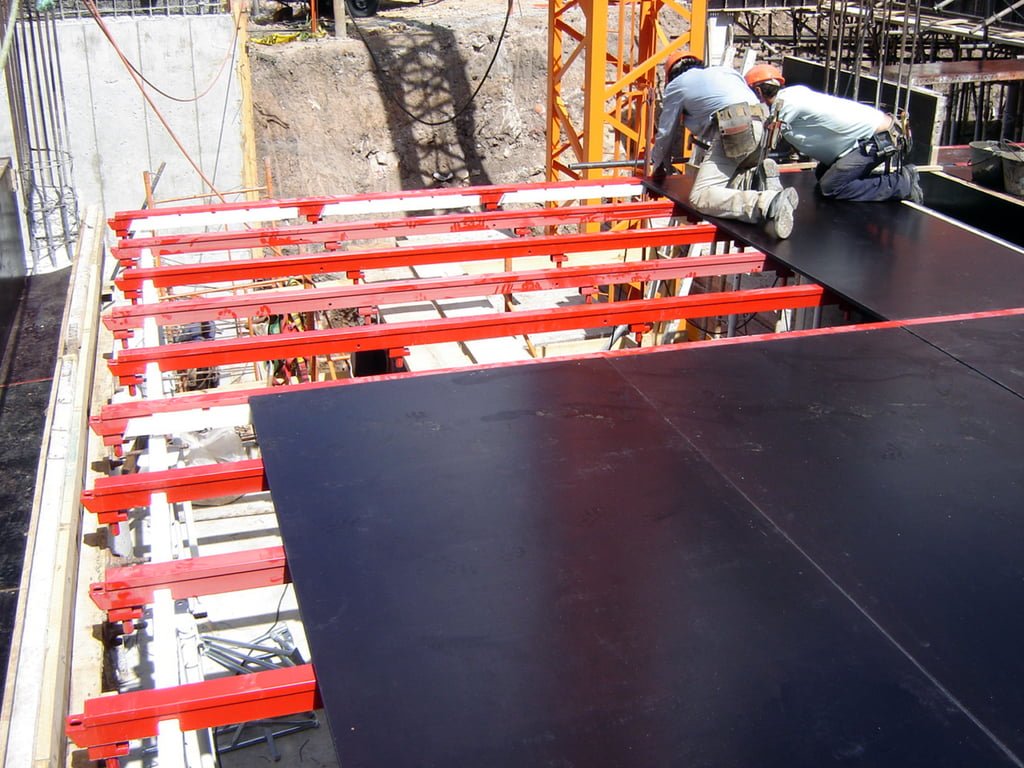

If you’ve ever stripped a slab and found patchy concrete, swollen panel edges, or a board that “let go” halfway through a pour, you already know the truth: Plywood for Formwork isn’t just plywood. It’s a jobsite tool. If it fails, your crew spends the weekend grinding concrete instead of moving to the next pour.

This guide is written for contractors, site engineers, and buyers who want formwork plywood that actually matches their pour conditions, reuse targets, and QA requirements. We’ll break down the key specs in simple language and then show how they come together in a real-world spec example using Kosmex film faced plywood – especially their high-density film options in the ~145–220 g/m² range and machine-jointed core construction.

Start with the job (not the price): what are you pouring?

The worst time to discover you chose the wrong plywood is when you’re stripping. So instead of starting from price, start from the reality of your site:

- Concrete finish: fair-faced / architectural surfaces need cleaner film and flatter sheets; car parks and hidden slabs are more forgiving.

- Reuse target: do you need 3–5 uses, or are you trying to push it into double digits?

- Exposure: are panels stored under a roof, or sitting in the rain between pours?

- Fastening & handling: heavy screwing, crowbars, crane lifting and drops punish weak cores fast.

- Geometry: slabs and simple walls can live with more flex; beams, edges and columns cannot.

Once you answer those, you’re no longer asking “cheap vs expensive” plywood. You’re asking the better question: “What spec fits my pour + cycles + finish?”

Formwork plywood is a system: core + glue line + film

A good sheet behaves like a system:

- Core gives you stiffness and screw-holding strength.

- Glue line keeps everything together when moisture and load try to tear it apart.

- Film overlay protects the surface, helps concrete release, and decides how the concrete actually looks.

Most “bad plywood stories” on site come from one of three things: weak core construction, low-grade or thin film, or poor moisture control in production and storage.

Film GSM: where concrete finish and reuse are really decided

“Film faced plywood” is not a spec. It’s a category. What you actually care about is the film weight (GSM) and the quality of the film itself. Higher-density film (higher GSM) usually means:

- better surface durability and abrasion resistance across reuses,

- more consistent concrete release,

- slower wear-down at corners and edges when your crew is working fast.

In this guide, we focus on high-density film programs roughly in the 145–220 g/m² range — the kind of film spec you discuss when your goal is reusable formwork, not disposable one-off sheets. Kosmex’s film faced product line includes different film weights (from eco to heavier-duty segments), so buyers can match film GSM to their reuse target instead of guessing.

For deeper background (not from a competitor), APA Wood Europe offers a neutral design & construction guide for concrete forming:

Design / Construction Guide: Concrete Forming (APA Wood Europe)

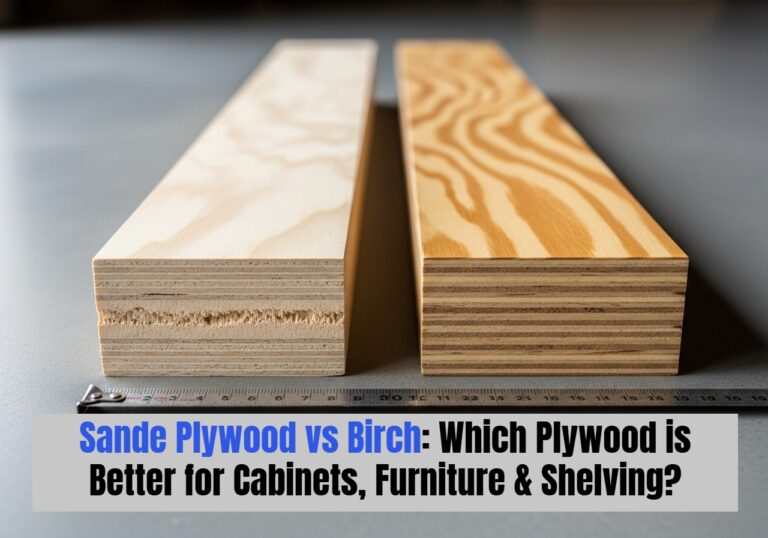

Core quality: why composer-machine cores matter on real jobs

The film is what you see. The core is what decides whether the sheet survives. Typical problem cores have:

- voids and holes that crush under pressure,

- overlapping veneers that create high spots and stress lines,

- poorly jointed veneer strips that open up when moisture changes.

Kosmex tackles this at the production level using a core veneer composer machine. According to their technical content, the composer machine:

- joins core veneers with clean, uniform connections,

- helps eliminate gaps, overlapping veneers and internal voids,

- lets the glue penetrate evenly across layers for better internal bonding.

You can see this mentioned directly in: “Phenolic vs Melamine Glue in Plywood” (Kosmex) and in their factory machine list: Kosmex Machines System.

On site, a better core simply means fewer “mystery weak panels” in the middle of the stack and a more predictable response

when you load, strip, and reuse sheets in a tight schedule.

Basic paperwork: don’t overcomplicate, but don’t skip it

You don’t need a lab in your office. But you do want to know your supplier understands what they’re doing. For EU-oriented projects, plywood performance is usually framed against standards like EN 636 (use conditions / classification) and EN 314-2 (bond quality discussion). Kosmex references these EN standards across several technical pages when discussing phenolic-bonded plywood and formwork applications.

At minimum, ask any supplier for:

- a technical data sheet (sizes, film type, density, application notes),

- a clear statement of bonding system (e.g. phenolic / WBP-class systems for construction use),

- how they control moisture content of veneers and panels,

- a short summary of their QC and testing flow (what defects get rejected, what’s tested in the lab).

Kosmex makes this easier by publishing: QC Process, Lab Test System, and a Test Report Library that buyers can refer to during qualification.

Handling: how to stop wasting good plywood

Even high-spec panels die early if they’re treated like rough packing boards. A few simple habits can easily add extra cycles.

Use a proper release agent (and go light)

- Use a release agent that’s compatible with film faced plywood.

- Apply a thin, even coat—puddles cause staining and can damage the surface over time.

Clean after stripping

- Knock off concrete residue before it fully cures.

- Avoid tools that gouge the film—most water ingress starts at damaged spots.

Protect and reseal edges

Kosmex notes that film faced panels leave the factory with edges sealed using waterproof paint, but jobsite cutting and impact will expose new edges. Touch up exposed edges and tie-rod holes with paint or sealant whenever you see raw wood.

Store flat and dry

- Stack panels flat on bearers; avoid leaving them in standing water.

- Cover bundles from rain and direct sun; let air flow to avoid trapping moisture.

Quick inspection checklist (before you accept the shipment)

You don’t need special tools—just look at a few sheets from the middle of the bundle, not only the top.

- Face film: no big bubbles, overlaps, or clearly burned patches; printing and color look consistent.

- Edges: sealed, not crushed; no open gaps or “missing” sections of veneer.

- Core line: look at the edge; avoid obvious voids and messy overlaps.

- Flatness: put two panels face-to-face—excessive rocking means alignment problems later.

- Random thickness checks: uneven thickness shows up as lines in concrete and makes panel joining harder.

Why many buyers move from “no-name plywood” to a spec like Kosmex

On paper, a lot of offers look similar: “film faced plywood, WBP, 18mm, 1220×2440.” In practice, buyers switch away from no-brand sheets for three reasons:

- Inconsistent core: too many weak boards buried in each bundle.

- Unclear bonding: labels say “WBP” but fail under real moisture and handling.

- No real QC story: nothing to show clients when something goes wrong.

Kosmex positions itself as a Vietnam plywood producer focused on documented quality:

- High-density film options for formwork, including heavier GSM programs suitable for reuse-focused buyers.

- Machine-jointed core using a composer machine to reduce gaps, overlaps and internal voids. :contentReference[oaicite:3]{index=3}

- Transparent factory setup (machines page, QC process, lab test page, test report library).

You can see a neutral company profile here: Kosmex profile on GlobalWood.

That combination (film GSM you can specify + machine-jointed cores + published QC) is what many serious buyers now look for

when they want to move away from anonymous shipments and towards a repeatable spec.

RFQ template you can send to Kosmex (or any serious supplier)

Copy, adjust, and paste this into your email/WhatsApp:

- Project type: [slab / wall / column / bridge deck] – target reuse: [X] cycles

- Panel size: [1220×2440 / 1250×2500 / other]

- Thickness: [12 / 15 / 18 / 21mm] + tolerance expectation

- Film: high-density phenolic film, target range ~145–220 g/m² depending on your recommendation

- Core: hardwood/mixed hardwood – please confirm how core voids/overlaps are controlled

- Bond / EN references: suitable for concrete formwork; share related EN 314-2 / EN 636 test references where available

- QC & documents: available test reports + brief QC process summary

- Quantity & terms: [X] m³ or [X] sheets, [FOB/CIF] [port name]

For more background before you send the RFQ, you can review: Kosmex Film Faced Plywood and Phenolic vs Melamine Glue in Plywood.

Conclusion: match the sheet to your cycles, not just your budget

If you only remember one thing from this guide, make it this: choose plywood by pour type + reuse target + finish requirement, not just by price.

When you prioritize film GSM, core construction, and basic, honest paperwork, you dramatically reduce the chance of surprise failures, patchy concrete, and last-minute sheet replacements when the schedule is tight.

If you want a formwork plywood spec tuned to your project and an offer backed by a clear QC story, you can contact Kosmex directly:

- Company: KOSMEX CO., LTD.

- Registered address: House No. 5, Lane 205/37/26, Xuan Dinh Street, Trung 2 Residential Area, Xuan Dinh Ward, Hanoi City, Vietnam

- Factory location: Yen Son District, Tuyen Quang Province, Vietnam

- Phone / WhatsApp: +84 399 741 589

- Email: anna@kosmexgroup.com / anna.kosmex@gmail.com

- Contact page: https://kosmexgroup.com/en/contact/

Request a Formwork Plywood Quote from Kosmex

FAQ

1) What thickness plywood is usually used for formwork?

Common thicknesses are 12–18mm for many slabs and general shuttering jobs. Heavier sections and longer spans often use 21mm. The right choice depends on load, support spacing, and how many times you expect to reuse the panel.

2) Is WBP always required for formwork plywood?

For construction use where panels are exposed to water, you want a glue system that can handle moisture cycles. In practice, contractors often prefer phenolic or WBP-type bond systems when they’re aiming for repeated reuses.

3) How many times can film faced plywood be reused?

There is no single number. Reuse depends on film GSM, core quality, and how the panels are handled. High-density film + good core + careful handling can reach significantly more cycles than low-density film and rough handling. Suppliers can share test-based examples for their own products.

4) What film GSM should I choose?

If you only need a few pours, a lighter film can be economical. If you’re chasing more cycles or a cleaner architectural finish, many buyers start around

145–180 g/m² and go higher for tougher jobs, assuming site handling is disciplined.

5) What causes delamination in formwork plywood?

Typical contributors include: repeated wetting and drying, poor bonding, core voids and overlaps that create stress points, and damaged/untreated edges that let water in. Good production and good site habits are both needed.

6) What documents should I ask for on EU-focused projects?

At minimum, ask for a clear technical data sheet, intended use description, and EN-related test references (e.g. bonding and classification aligned with EN 314-2 / EN 636 discussions). For background, APA Wood Europe provides useful summaries:

Bình luận