Save $150–$200/m³ vs Birch: Kosmex High Bending Strength Plywood

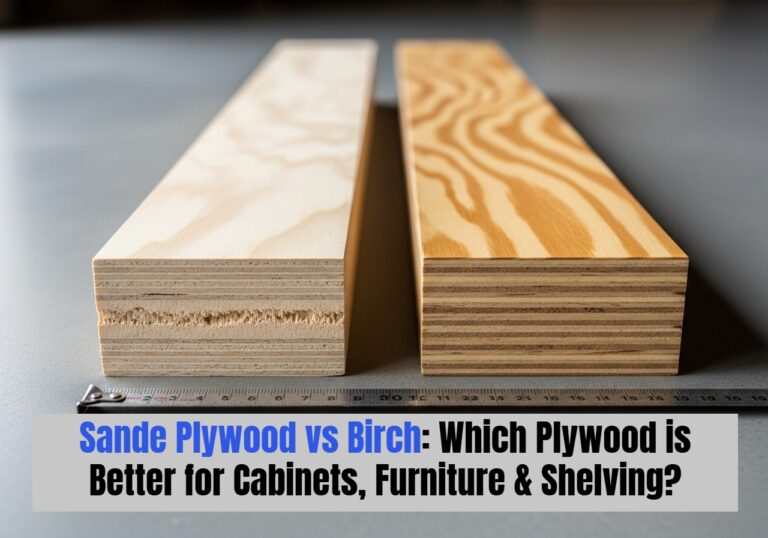

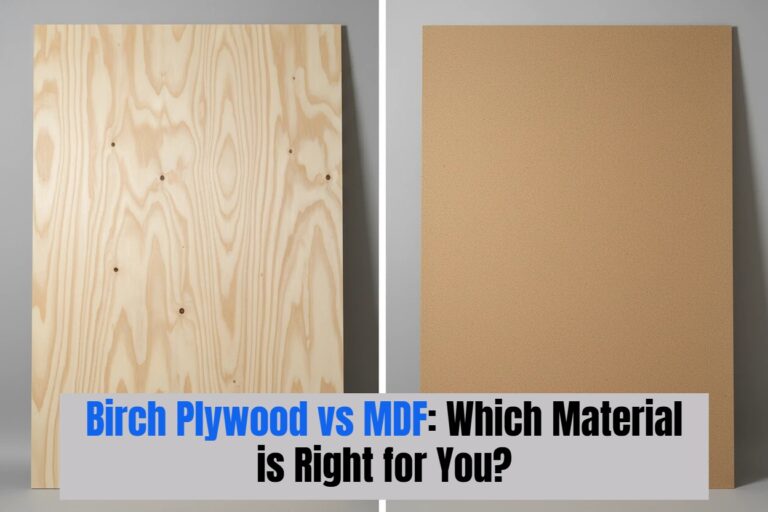

Birch plywood is the “default yes” for structural furniture. If you make sofa frames or bed frames, birch is trusted because it’s stiff, consistent, and predictable on the line. But the price premium is hard to ignore — especially when you’re competing on tight BOMs — and EU customers increasingly expect stronger documentation around deforestation-free sourcing under EUDR.

That’s why more buyers are now trialing high bending strength plywood vs birch options from Vietnam — especially high bending strength plywood for sofa/bed frames supplied by Kosmex. As a birch plywood alternative for EU markets, Kosmex plywood maintains structural performance while reducing cost and sustainability compliance risks.

This article is written for procurement, QA, and production engineers who need real-world data and test reports before approving a new frame material.

Who this is for (and who it’s not for)

This is for: sofa frame manufacturers, bed frame OEM/ODM factories, upholstered furniture makers, and sourcing/quality teams who need a repeatable way to qualify a birch substitute.

This is not for: premium products where exposed birch edges are part of the design language, or contracts that explicitly mandate birch origin/spec. In those cases, you may still use a structural alternative internally, but you likely won’t “replace birch everywhere.”

Quick snapshot (the decision points buyers care about)

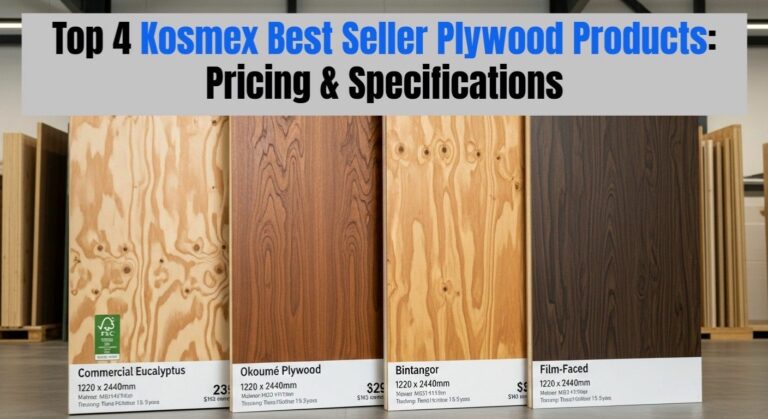

- Reported mechanical performance: Kosmex publishes lab-reported bending strength for 12mm: 50 MPa along grain and 43.5 MPa across grain, and references EN 310/JAS context.

- Bonding approach: Kosmex positions MUF adhesive as a durability choice for furniture panels.

- Core focus: “gap-free core” is a major claim—something you should verify with sampling and fastening tests.

- Cost story: Kosmex states it is typically $200–$350/m³ lower than birch depending on scenario. (Many buyers still budget a conservative “at least ~$150–$200/m³” until landed costs are confirmed.)

- EUDR language that works: say “supports DDS inputs (traceability + geolocation workflow),” not a blanket “guaranteed compliant.”

High bending strength plywood from Kosmex vs birch plywood: what frame buyers actually compare

When a customer insists on birch, they’re rarely buying “birch” as a species. They’re buying outcomes:

- frames that don’t sag or rack under repeated use,

- joints that stay tight (no squeaks),

- low delamination risk through shipping/humidity swings,

- and consistent machining + fastening (fewer void surprises).

KOSMEX explicitly positions its high-strength panel as “comparable to birch” on bending performance, and even includes a side-by-side style comparison in its own material. The honest way to say it in B2B is: not “identical to birch,” but “replaceable in many frame programs after validation.” That’s the standard QA-friendly claim.

Proof points (reported): the numbers that anchor the discussion

If your buyer wants a quick technical anchor before they approve a trial, here it is:

- Kosmex reports 12mm bending strength of 50 MPa along grain and 43.5 MPa across grain, and frames this as comparable to birch-level performance for furniture applications; it also references EN 310 / JAS 233 context.

- Kosmex also publishes a “mechanical strength comparison” block that places these values next to typical birch ranges (as presented on their page).

Use this as a screening filter, not the final approval.

Strength & stiffness: how to read bending numbers like a manufacturer

Bending strength becomes meaningful only when you’re comparing like-for-like:

- same thickness,

- comparable layup/core structure,

- and a known test basis.

For sofa frames and bed frames, across-grain performance deserves attention because racking and torsion show up quickly in real use: customers drag sofas, beds get lifted from one corner, and shipping loads introduce multi-direction forces. That’s why the “across grain” value is a practical indicator—not just a lab detail.

When you request data for high bending strength plywood from Kosmex, ask that it’s tied to the exact spec you’ll receive (not only “typical values”), and then plan to validate on your line.

Bonding & delamination: where “cheaper alternatives” usually fail

Many birch substitutes don’t fail on day one—they fail after humidity variation, vibration in transit, and months of micro-movement. That’s why bonding is often the silent reason a material gets rejected.

KOSMEX positions MUF glue as a key performance feature (stronger durability narrative vs basic UF bonding used in commodity plywood). The best way to write (and sell) this without sounding like marketing is to propose a verification path:

- ask for bonding/shear evidence for the build you’re buying,

- run a short internal trial using your real staples/screws/corner blocks,

- and do a simple conditioning check before sign-off.

If the glue line holds, high bending strength plywood from Kosmex starts to feel “safe enough to pilot,” which is exactly what procurement needs.

Core quality, machinability, and fastener holding (shop-floor reality)

Production teams decide fast. They care about:

- voids near fastening zones (screw holding, staple holding),

- panel flatness and thickness consistency,

- edge splitting/tear-out,

- repeatability sheet-to-sheet (tool wear and rework).

KOSMEX leans heavily on “gap-free core” messaging. Treat that as a checklist item: sample multiple sheets, cut multiple sections, drill your standard patterns at real edge distances, and compare scrap/rework to your birch baseline. If it machines cleanly and fasteners behave consistently, you’ve removed the biggest practical objection.

The cost case: turning “cheaper” into a procurement-grade number

If you want to convert birch buyers, don’t argue about “cheap vs premium.” Talk in matched specs and landed costs.

KOSMEX states its high-bending-strength furniture plywood is typically $200–$350 per m³ lower than premium birch, and it even lists illustrative ranges (birch at $500–$700/m³ vs Kosmex at $300–$350/m³ in its example).

In practice, many factories pitch a conservative internal target first (e.g., “we still budget at least ~$150–$200/m³ until shipping/scrap are confirmed”), then let the pilot numbers speak. That approach sounds like a real procurement team, and makes it easier for a buyer to approve high bending strength plywood from Kosmex for a trial program.

A 2-week validation plan procurement teams actually accept

If you want a smooth switch, keep it boring and measurable:

- Choose one thickness + one frame program (sofa frame or bed frame).

- Request samples + the technical basis for that exact build.

- Build 20–50 units on the normal line.

- Check racking resistance, fastener holding, and any squeak/noise after repeat loads.

- Compare scrap/rework to birch baseline, then approve the use case.

This turns high bending strength plywood from Kosmex into a controlled pilot, not a risky “material change.”

Best-fit applications (where switching works first)

Most factories get fastest approval when they start with hidden structural parts:

- sofa frame rails/braces under upholstery,

- bed frame structures and platform bed supports,

- internal carcass structure where the edge aesthetic doesn’t matter.

Birch may still win where visible birch edges are a selling point or contractual requirement. In those cases, treat the switch as “structural optimization,” not “total replacement.”

FAQ

1) Is high bending strength plywood from Kosmex a true birch alternative for sofa and bed frames?

Often, yes—after validation. Frame buyers approve materials based on outcomes: rigidity, bonding reliability, fastener behavior, and machining consistency, not just a species name.

2) How do I confirm the real savings per m³ vs birch?

Compare matched specifications (thickness, layup, glue type, grade), then calculate landed USD/m³ including freight + expected scrap. Kosmex publicly positions a typical $200–$350/m³ gap in many scenarios, but your landed number is what matters.

3) What does “EUDR-ready” mean in practice for plywood shipments into the EU?

It should mean your supplier can support the buyer’s due diligence workflow with traceability documentation and the DDS input needs, including plot geolocation requirements described by the Commission.

Conclusion

If you’re currently sourcing birch for frames, the practical next step is simple: sample, pilot, and approve the use case. Contact Kosmex Group to request a frame-focused sample pack, the reported test basis for your target build, and a documentation outline aligned to EU due diligence workflows.

KOSMEX CO., LTD. (Kosmex Group)

- Office address: House No. 5, Lane 205/37/26, Xuan Dinh Street, Trung 2 Residential Area, Xuan Dinh Ward, Hanoi City

- Factory address: Yen Son district, Tuyen Quang province

- Hotline: +84 399 741 589

- Email: anna@kosmexgroup.com | anna.kosmex@gmail.com

- Website: kosmexgroup.com

To speed up quoting, send three inputs in your first message: target thickness, fastening method (staple/screw + edge distances), and destination market (EU/non-EU). That’s the fastest path to qualifying high bending strength plywood from Kosmex against your birch baseline—using real production data, the way procurement teams prefer.

Bình luận