Phenolic vs Melamine: The Complete Guide for Furniture and Formwork Plywood Buyers

Furniture and formworks manufacturers are becoming more selective with glue technology as durability, moisture resistance, and international compliance become non-negotiable requirements. Understanding the difference between phenolic vs melamine glue is essential for anyone producing sofa frames, bed bases, cabinets, or structural plywood where long term reliability matters.

Kosmex is a Vietnam plywood manufacturer specializing in phenolic plywood for EU markets, trusted for consistent bonding strength and export grade quality. We supply Vietnam plywood for furniture and formwork certified with CE and FSC, ensuring performance that meets international standards.

What is Phenolic Glue in the Plywood Industry

Phenolic glue is a synthetic resin created from phenol and formaldehyde. It is widely considered the gold standard for exterior grade plywood and heavy duty structural applications. When cured at high temperature, phenolic resin forms a dark glue line that is waterproof, heat resistant, chemical resistant and extremely strong under mechanical stress.

In professional environments such as construction formwork, marine use, industrial furniture or outdoor cabinets, phenolic glue provides performance that cheaper adhesives cannot replicate. Once the glue line is cured, it becomes completely thermoset. It does not soften again even under extreme moisture or temperature changes. This makes plywood bonded with phenolic glue suitable for long term load bearing tasks.

Because of its strength and resilience, phenolic glue is required for most European and American structural standards including EN 314 and EN 310 bending strength requirements.

Read more: High Bending Strength Plywood for Furniture: The Complete Buyer’s Guide for Manufacturers

What is Melamine Glue and where it is used

Melamine glue is produced from melamine and formaldehyde. It has better moisture resistance than pure urea glue but it is not as durable as phenolic resin. Melamine bonded plywood is generally suitable for interior furniture, shelves, partitions and decorative items. It performs well in dry environments but does not reach the same structural stability as phenolic bonding.

Melamine glue softens more easily under heat and extended exposure to humidity. When used in formwork or outdoor applications, its bonding strength can decrease over time. Therefore, melamine is typically chosen for cost sensitive projects or products not intended to support heavy loads.

Key Differences between Phenolic vs Melamine glue

Although phenolic vs melamine adhesives may look similar during production, their long term performance is not comparable.

Phenolic adhesives deliver superior bonding strength, especially for bending stress and high load applications. They resist boiling water, strong solvents and decades of repeated use without weakening.

Melamine adhesives provide moderate bonding stability. They offer acceptable water resistance for indoor furniture but degrade faster under heavy mechanical pressure.

Phenolic glue maintains shape under extreme bending forces, which explains why phenolic bonded plywood often passes EN 310 bending modulus of rupture and modulus of elasticity tests with high results. Melamine bonded plywood typically fails at lower loads.

Phenolic adhesives retain strength in humid, outdoor and construction environments. Melamine adhesives perform best only in controlled indoor conditions.

Phenolic resin ages slowly and remains stable for many years. Melamine resin shows faster aging, particularly when exposed to high temperature drying cycles.

Why Phenolic glue makes Kosmex Plywood stronger and more reliable

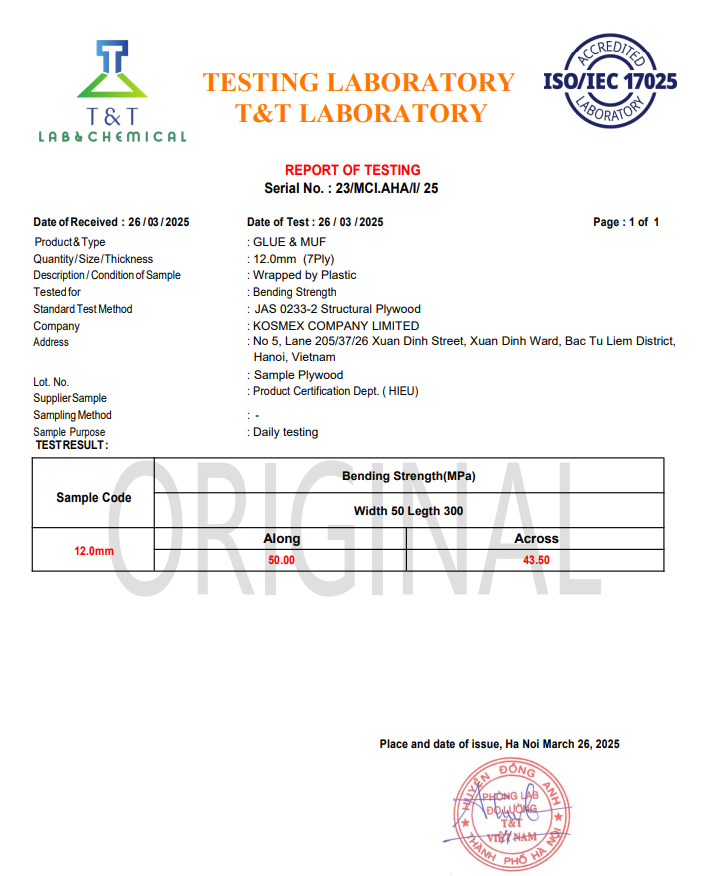

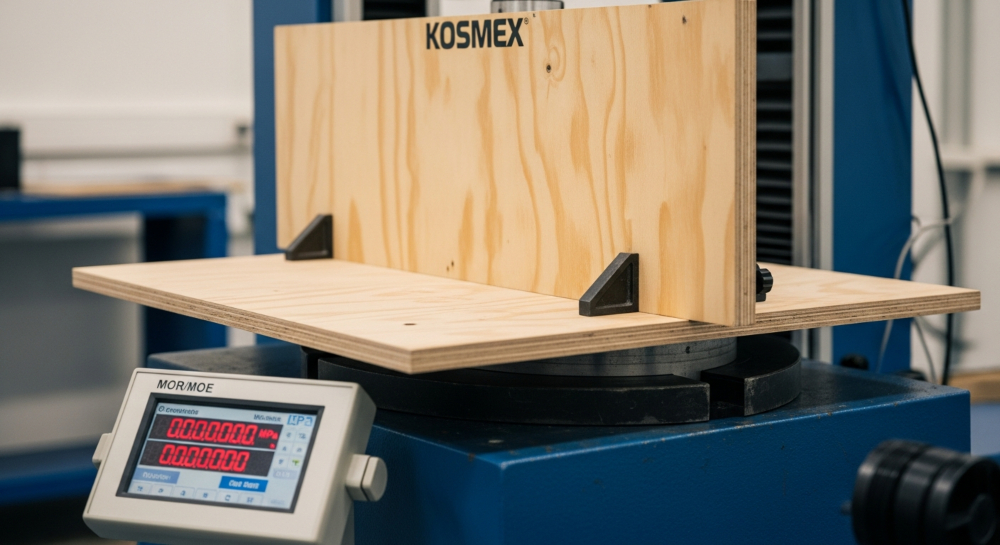

Kosmex manufactures high bending strength plywood using phenolic adhesive that meets strict European requirements. The difference is visible not only in laboratory test reports but also in real world performance.

In March 2025, Kosmex 12 mm plywood recorded bending strength of 50 MPa along the grain and 43.5 MPa across the grain under JAS 0233 testing. These numbers are remarkably high, reaching the performance of premium birch plywood imported into the EU and US markets.

Kosmex uses phenolic glue consistently across its structural and film faced plywood lines. This results in a hard, waterproof and extremely durable glue line.

Kosmex plywood displays higher resistance to bending and deflection under heavy loads, making it suitable for sofa frames, bed platforms, cabinets and formwork panels.

Phenolic adhesive allows Kosmex panels to remain stable in shipping containers, cold environments, humid tropical climates and seasonal temperature changes.

This performance positions Kosmex as a premium commercial plywood supplier whose products are strong enough for structural furniture, yet more affordable than birch plywood.

Core Construction: Machine Jointed vs Hand Jointed Cores

Adhesive alone does not determine plywood quality. The way core veneers are jointed also affects the strength of the panel. Kosmex uses a composer machine to join core veneers which creates clean and uniform connections.

Machine jointed cores eliminate gaps, overlapping veneers and internal voids. As a result, the glue can penetrate evenly across layers, creating strong internal bonding.

Hand jointed cores found in many local Vietnamese suppliers often show holes, overlap marks and weak spots. These defects reduce the effective glue contact areas, lowering bending strength and long term durability.

When combined with phenolic glue, Kosmex machine jointed cores produce a significantly stronger panel compared to melamine bonded plywood with hand jointed cores.

Surface Quality: High Density Film vs Low Density Film

When compare phenolic vs melamine, For film faced plywood, the surface veneer also determines how long the product lasts.

Kosmex uses high density film veneer ranging from 145 to 180 grams per square meter. This results in a smooth surface without burning marks, bubbles or overlaps.

Other suppliers often use low density film veneer between 90 and 100 grams per square meter. These surfaces show defects quickly and wear out after fewer reuse cycles.

Phenolic film combined with high density surface veneer ensures long formwork life and professional finishing quality.

Price Comparison: Phenolic Bonded Kosmex Plywood vs Birch Plywood

Birch plywood is popular in European and US markets because of its high strength. However, birch is expensive and prices often fluctuate depending on supply.

Kosmex plywood offers similar mechanical performance at a more competitive price, typically lower by 100 to 150 dollars/ m³ compared to full birch plywood.

This positions Kosmex as a premium commercial plywood option. Buyers receive a strong and durable product with phenolic glue bonding, excellent bending strength, reliable surface quality and strict QC without paying the high cost of birch.

For large orders from furniture factories, bed manufacturers or construction companies, the cost advantage becomes highly significant.

Why Melamine Bonded Plywood Is Not Suitable for Heavy Duty Use

Some suppliers promote melamine bonded plywood as a cheaper option for structural furniture. However, melamine adhesive cannot match the performance of phenolic resin.

Melamine glue weakens faster under cyclic loads and repeated stress. It absorbs moisture over time and loses rigidity. When used in bed frames or sofa supports, melamine plywood can deform sooner than phenolic bonded panels.

Melamine is suitable for decorative furniture, partitions or lightly loaded shelves. For structural applications, buyers should select phenolic bonded panels if long term safety and product reliability are priorities.

Certifications That Confirm Kosmex Quality

International buyers carefully check for third party certifications when evaluating plywood suppliers. Certifications signal credibility and compliance.

Kosmex holds FSC certification which confirms responsible forest management and traceable sourcing.

Kosmex also holds CE certification Vietnam plywood, which is essential for exporting to the European Union and demonstrates that the product meets safety and performance standards.

Laboratory test reports for bending strength, MOR and MOE, adhesive quality and surface stability further validate Kosmex manufacturing standards.

These documents make Kosmex a trusted supplier for customers in Europe, Australia, Japan and across Asia who prioritize long term partnerships.

Read more: What Is a CE Certificate? Everything You Need to Know

Practical Buying Advice for Phenolic vs Melamine Plywood

When choosing between phenolic bonded plywood and melamine bonded plywood, the most important factor is the purpose of your project. Phenolic plywood is engineered for strength, durability and long-term stability. It is the superior choice for any application that must carry weight, handle moisture or maintain performance over many years. This includes sofa frames, bed bases, cabinetry exposed to frequent movement, industrial work surfaces, construction formwork and environments with high humidity.

Melamine plywood, by contrast, performs best in light-duty interior settings. It is suitable for decorative wall panels, wardrobe separators, small shelves and furniture pieces that do not bear heavy loads. While cost-effective in the short term, its bonding strength and moisture resistance are significantly lower, making it unsuitable for structural or demanding applications.

If your goal is reliability, safety and long-term product value, phenolic bonding consistently delivers better performance and lower lifecycle cost. The comparison below summarizes the key differences:

| Property | Phenolic Glue (Phenol Formaldehyde Resin) | Melamine Glue (Melamine Formaldehyde Resin) |

| Water Resistance | Excellent. Complies with WBP (Weather and Boil Proof) standards. | Moderate. Complies with MR (Moisture Resistant) standards. |

| Bonding Strength | Very High (Very Strong). Offers high bond grab. | Medium to Strong. |

| Heat Resistance | High. Ideal for applications with high thermal factors. | Moderate. Sufficient for most indoor applications. |

| Suitable for Outdoor Use | Yes. Superior water and heat resistance make it ideal for exterior use. | No. Not suitable for prolonged water exposure. |

| Suitable for Heavy Load | Yes. Provides a stronger and more long-lasting plywood structure. | Limited. Offers good durability for indoor use but not harsh environments. |

| VOC Emissions (Formaldehyde) | Can be higher. | Can be higher, but low-formaldehyde MUF (Melamine Urea Formaldehyde) options exist. |

| Typical Applications | Structural, formwork (concrete formwork), marine applications, container flooring and demanding environments. | Indoor decorative furniture, cabinets, countertops and applications requiring moderate moisture resistance. |

| Cost | Expensive (due to superior properties). | Less Expensive than Phenolic. |

| Lifespan | 20-50+ years (Excellent durability). | 5-10 years (Good durability for indoor applications). |

| Compliance with EN 310 (Bending Strength) | Yes (Applicable to high MOR/MOE plywooplywood). | Not typically (Applicable to lower bending strength requirements). |

For manufacturers producing export-grade furniture, frames, cabinetry or industrial plywood products, phenolic glue provides a clear performance advantage. Its superior mechanical strength, excellent moisture resistance and long-term stability make it the preferred bonding system for companies seeking to deliver durable, high-value plywood that meets international standards and customer expectations.

Why EU buyers prefer Phenolic Plywood from Vietnam

European importers place strict requirements on bonding strength, moisture resistance, emissions and long term structural stability. For this reason, phenolic bonded plywood from Vietnam has become a preferred choice for EU markets. The combination of high MOR/MOE values, strong internal bonding and excellent water resistance provides a level of reliability that melamine bonded plywood cannot match.

Vietnam phenolic plywood that is manufactured under CE and FSC standards also meets the environmental and compliance expectations of European distributors. Consistent factory quality control, machine jointed cores and stable supply chains make Vietnam plywood a dependable option for furniture manufacturers, formwork suppliers and wholesalers across Europe. For EU buyers who need predictable performance and certification ready documentation, phenolic plywood from Vietnam offers superior long term value.

Conclusion: Why Kosmex Phenolic Plywood is the superior choice

The global plywood market is moving toward stronger, safer and more durable bonding technologies. Phenolic bonded plywood from Kosmex offers structural reliability, high MOR and MOE performance, and long term stability that melamine bonded boards simply cannot match.

If you are looking for a dependable plywood source that meets international standards, Kosmex is ready to support you with:

- Free samples in the exact thickness and core specification you need

- Export quotes for EU, US, Middle East and Southeast Asian buyers

- One to one technical guidance for sofa frames, bed frames, cabinets and structural components

- Full FSC, CE certifications and test reports following JAS and EN requirements

To request samples or pricing, please email Kosmex or contact our WhatsApp or email: anna@kosmexgroup.com

For technical consultation, our engineering team can help you choose the right plywood based on load, environment and design.

Bình luận