High Bending Strength Plywood for Furniture: The Complete Buyer’s Guide for Manufacturers

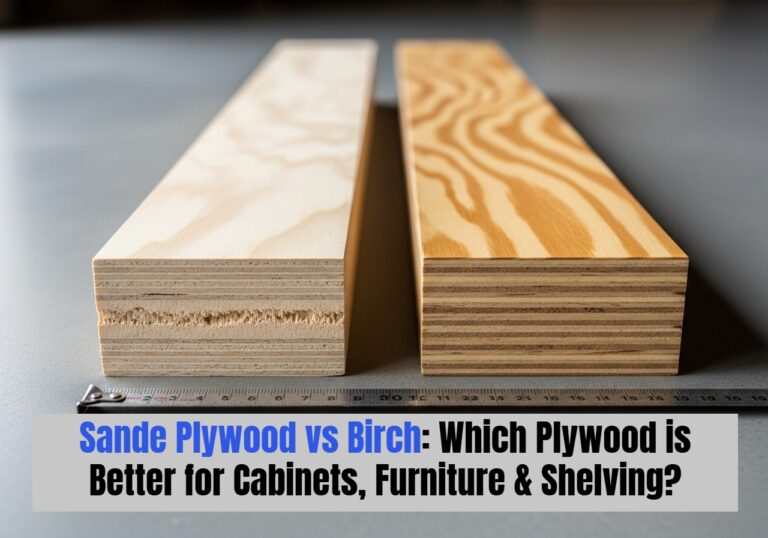

Global furniture manufacturers face a critical decision in 2026: continue relying on expensive Birch plywood or switch to innovative high bending strength plywood for furniture that matches performance at significantly lower costs.

European and North American manufacturers are already making this transition, replacing conventional MDF and commercial-grade plywood with advanced engineered solutions. This comprehensive guide reveals why premium furniture-grade plywood is transforming the industry, how to evaluate quality and why Kosmex is leading this revolution in Vietnam.

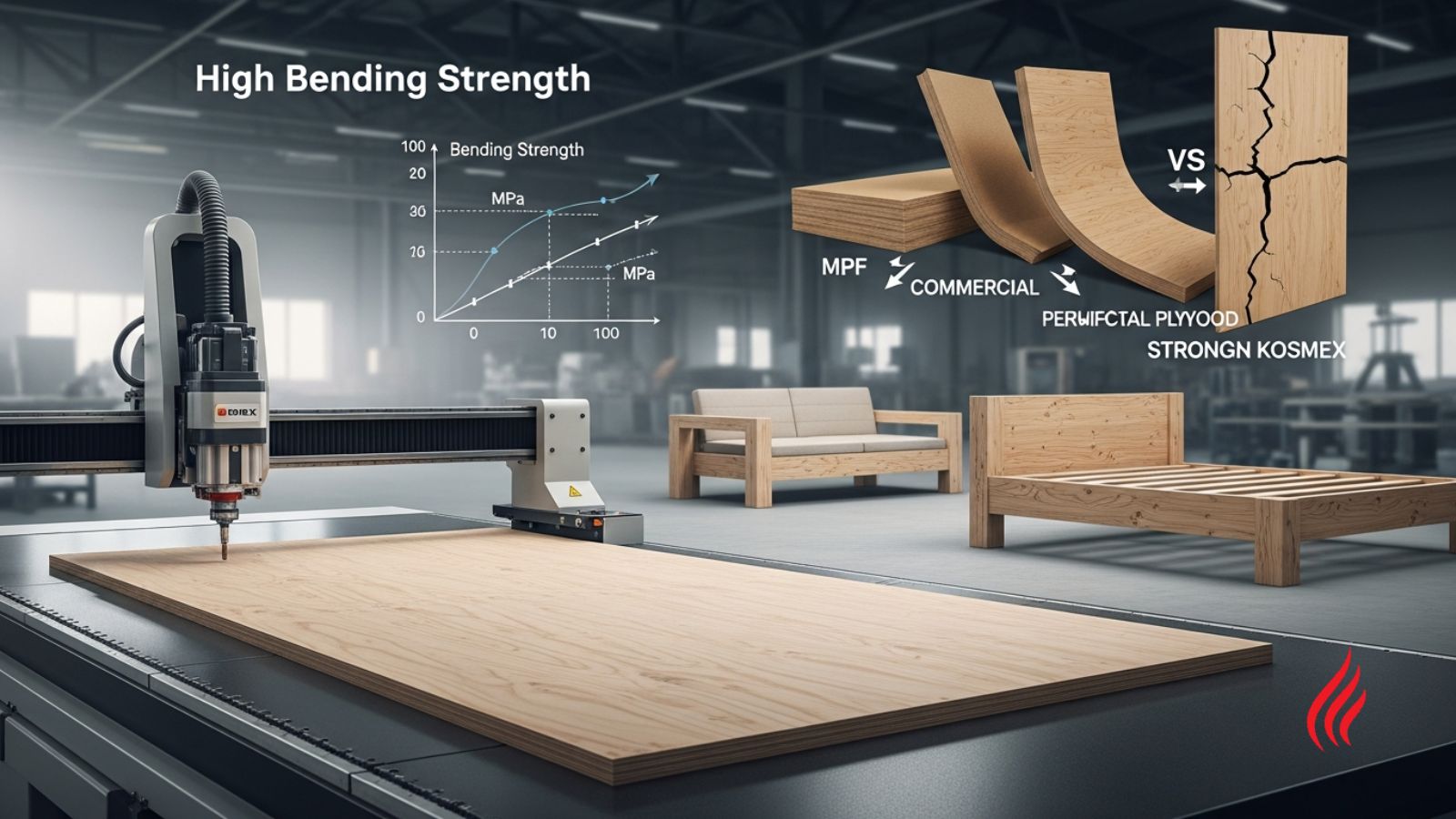

Why High Bending Strength Plywood Is Changing Modern Furniture Manufacturing?

Furniture manufacturers across EU and US markets increasingly demand high bending strength plywood as an alternative to expensive 100% Birch. Sofa and bed frame producers are abandoning traditional MDF and commercial plywood because these materials fail under real-world stress, causing sagging, squeaking, and structural failure within 2-3 years.

Bending strength determines how much weight a material supports before permanent deformation or breaking. Premium high bending strength plywood maintains integrity for decades, making higher initial investment cost-effective through extended product lifespan and reduced warranty claims.

Kosmex 12mm Plywood: Lab-Verified Performance Data & Technical Specifications

Kosmex laboratory testing demonstrates exceptional performance: 50 MPa along the grain and 43.5 MPa across the grain, directly comparable to 100% Birch plywood. These metrics align with stringent EN 310 Europe and JAS 233 Japanese standards and exceed international furniture requirements.

Independent verification confirms that Kosmex plywood performs identically to premium Birch while maintaining manufacturing advantages.

7 reason why Kosmex Plywood outperforms other suppliers

Vietnam hosts numerous plywood manufacturers, but most prioritize volume over quality. Kosmex distinguishes itself through unwavering commitment to specifications and transparency. Here’s what sets Kosmex apart:

Exceptional Bending Strength (Up to 50 MPa) Comparable to 100% Birch

Kosmex consistently achieves 50 MPa along the grain, matching premium European Birch specifications. This performance ensures furniture can support substantial weight loads without permanent deformation. Independent laboratory certification proves these claims without relying on marketing hyperbole.

Superior Bonding Strength with MUF Glue for Zero Delamination

Most Vietnamese plywood uses urea-formaldehyde adhesive, which deteriorates under humidity and stress. Kosmex employs Melamine Urea Formaldehyde (MUF) glue, providing superior bonding that resists delamination even in challenging environmental conditions. Furniture made with Kosmex plywood maintains structural integrity throughout its lifespan.

Smooth Premium Surface Ideal for Lamination

Surface quality directly impacts finished product aesthetics and production efficiency. Kosmex plywood features consistently smooth surfaces without knots, gaps, or irregularities. This quality enables seamless lamination, veneer application and upholstery work, reducing secondary processing and waste.

Gap Free Core Construction

Many cheaper Vietnamese suppliers use plywood with core gaps, compromising structural integrity. Kosmex maintains strict quality control to eliminate core gaps entirely. A gap-free core means predictable performance and maximum structural stability for heavy-duty applications.

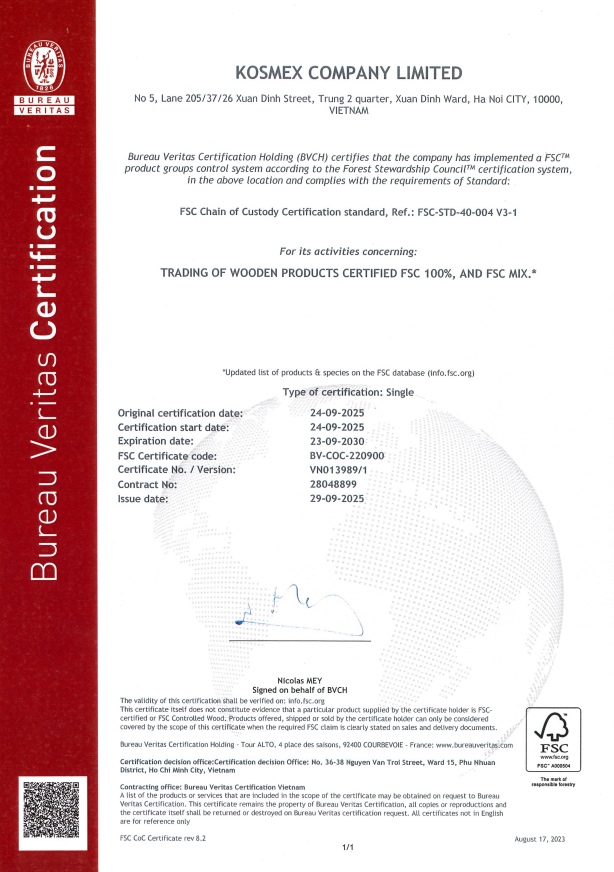

FSC and CE Certified for Global Export Compliance

International compliance matters. Kosmex holds Forest Stewardship Council (FSC) certification proving sustainable sourcing, plus CE certification guaranteeing European safety standards. These credentials open doors to discerning European and North American buyers who demand certified sustainable materials.

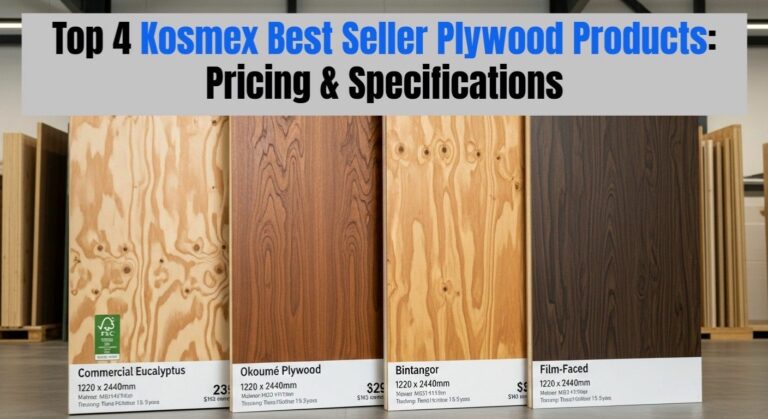

200-350 USD/m³ lower than Birch

Despite matching Birch performance, Kosmex plywood costs significantly less, typically USD 200 – 350 per cubic meter below premium European alternatives. This price advantage translates directly to manufacturer profit margins without sacrificing product quality.

Birch vs Kosmex High-Strength Plywood: Which Is Better for Furniture?

Mechanical Strength Comparison (Lab Data)

Independent laboratory testing provides clear performance comparison:

| Property | Kosmex HBS Plywood | 100% Birch Plywood |

| Bending Strength (Along Grain) | 50 MPa | 50-52 MPa |

| Bending Strength (Across Grain) | 43.5 MPa | 44-46 MPa |

| Bonding Strength | Excellent (MUF) | Excellent |

| Delamination Risk | Minimal | Minimal |

Cost Comparison (Per m³, Per Finished Product)

Raw material costs tell only part of the story. Consider total landed cost including freight, tariffs and waste:

- Birch Plywood (European): 500-700$/m3

- Kosmex Plywood: 300-350$/m3

- Net Savings per m³: $200-350 (40-50%)

Suitable Applications for Each Material

Birch plywood remains optimal for specialized applications requiring specific aesthetic qualities or when imported certification is contractually mandated. However, for structural furniture applications (bed frames, sofa bases, cabinet carcasses), Kosmex plywood delivers identical performance at substantially lower cost. Manufacturers can confidently specify Kosmex for 90% of furniture applications.

When Manufacturers Should Switch from Birch to Kosmex Plywood

The decision to transition from Birch to Kosmex plywood for furniture makes sense when:

- Manufacturers prioritize cost optimization without compromising quality

- Products require EU/US market compliance (FSC and CE certifications are critical)

- Lead times are critical (Kosmex delivers faster than European suppliers)

- Volume purchasing enables economy-of-scale benefits

- Sustainability credentials matter to target customers

4 usages of high bending plywood

Plywood for Sofa Frames

Sofa frame construction demands exceptional bending strength because frames endure continuous stress from sitting and reclining. Repeated bending cycles eventually weaken inferior plywood, causing frame sagging and squeaking noises that frustrate customers. Kosmex plywood’s 50 MPa bending strength ensures sofa frames maintain structural integrity for years. The importance of bonding strength cannot be overstated here, as frame components experience complex multi-directional forces. MUF adhesive prevents delamination that would compromise safety.

Plywood for Bed Frames and Platform Beds

Bed frames must support human weight while maintaining dimensional stability. Best plywood for furniture beds typically requires 15-18 mm thickness with exceptional bending strength. Queen and full-size beds distribute weight across large surface areas, making bending strength the critical performance factor. Kosmex plywood excels here, preventing the gradual sagging that reduces comfort and indicates structural failure to consumers.

Plywood for Cabinets and Drawers

Cabinet construction emphasizes surface smoothness and dimensional stability. Kosmex’s consistently smooth surface enables precise CNC cutting and seamless veneer application. Drawer boxes benefit from gap-free core construction that prevents racking (twisting) under load. Cabinet doors require flat, stable surfaces that resist warping, another area where Kosmex demonstrates superiority over standard commercial plywood for furniture.

How to Evaluate High-Strength Plywood Before Buying

Smart purchasing requires systematic evaluation. Use this checklist before committing to volume orders:

- Check core gaps: Visual inspection and X-ray testing reveals internal voids. Gap-free cores indicate quality manufacturing.

- Check glue bonding: Request shear strength testing data proving adhesive performance.

- Check bending strength certificate: Demand independent laboratory certification, not just supplier claims.

- Check moisture content: Plywood for furniture shipped with high moisture content expands/contracts causing warping.

Remember to use pre-purchase technical checklist.

- Check surface defects: Inspect for knots, splits and irregularities affecting finished product quality.

- Check FSC/CE certification: Verify compliance documentation for international market requirements.

- Compare weight density: Consistent weight indicates uniform core construction and quality control.

Where to buy high bending strength Plywood

Kosmex holds a unique market position in Vietnam. As the first and only supplier manufacturing 12mm high bending strength plywood at 50 MPa, Kosmex pioneered this category. Beyond product innovation, Kosmex offers:

- Direct factory supply with stable container quantities for bulk orders

- Export packaging and quality control procedures meeting international standards

- FSC and CE certification documentation included with every shipment

- Technical support and customization options for specific applications

Plywood for Furniture FAQs

Q: What is the best plywood for furniture?

A: The best plywood for furniture combines high bending strength (50+ MPa), strong bonding properties, smooth surfaces and gap-free core construction. Kosmex plywood meets all these requirements while offering cost advantages over European alternatives.

Q: Is Kosmex plywood good for making furniture?

A: Absolutely. Kosmex 12mm plywood delivers 50 MPa bending strength matching premium Birch while costing 200-350 USD/m³ less. With MUF adhesive bonding, gap-free core construction and FSC/CE certifications, Kosmex is specifically engineered for durable furniture. Sofa frames, bed structures and cabinets built with Kosmex plywood maintain integrity for decades without sagging, squeaking or delamination, making it the ideal choice for manufacturers prioritizing quality and profitability.

Conclusion

The global furniture industry is turning to smarter, more sustainable material choices. Kosmex high impact Plywood delivers Birch-like performance at a lower cost, with full international certification.

Are you looking for a stable, affordable and international standard plywood source?

Kosmex is ready to provide:

- Free samples in the exact thickness you require

- Container quotes for EU, US, Middle East and Southeast Asia markets

- 1:1 technical consultation for sofa frame, bed frame, cabinet and structure designers

- FSC, CE documents and test reports according to Japanese JAS

Get samples and quotes today: Please send your request via email or Kosmex’s WhatsApp/Zalo for support within 24 hours.

Schedule a technical consultation: Kosmex’s team of experts will help you choose the right plywood to suit your design, load and budget.

Bình luận